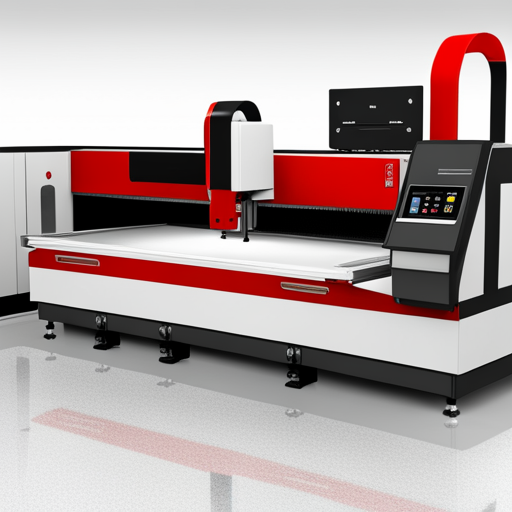

What is a Sheet Metal Laser Cutter?

A Sheet Metal Laser Cutter is a highly sophisticated piece of machinery used for precise cutting and shaping of metal sheets. It employs a high-powered laser beam that focuses on the material’s surface, heating, melting, and vaporizing it to achieve the desired shape or design. The cutter operates under computer numerical control (CNC), which ensures remarkable accuracy and efficiency in the process. This technology is widely used in various industries, including automotive, aerospace, and manufacturing, due to its ability to handle complex designs and high-volume production runs with minimal waste and maximum precision.

How does a sheet metal laser cutter work?

The operation of a sheet metal laser cutter hinges on a series of coordinated steps. First, the design to be cut is programmed into the CNC system. Upon initiation, the high-power laser beam, either of CO2 or fiber type, is guided onto the metal sheet by a series of mirrors. The intensity of the laser beam heats the metal and pierces through it, following the predetermined path set by the CNC program. An assist gas, usually oxygen or nitrogen, is concurrently used to blow away the molten metal, leaving a clean and precise cut. The cutter’s CNC capability allows for repeatable precision and efficiency, making it ideal for both simple and complex designs.

What are the advantages of using a sheet metal laser cutter?

Sheet Metal Laser Cutters provide a multitude of benefits that make them indispensable in today’s industries. Among these, the foremost is their precision and accuracy. The use of high-powered lasers guided by CNC programming ensures that intricate designs are cut with an extremely high degree of accuracy, which is typically measured in micrometers.

The second advantage is speed and efficiency. Laser cutters can handle high-volume production runs rapidly, significantly reducing manufacturing time. Their quick operation combined with the ability to work unattended (thanks to the CNC system) leads to considerable time savings.

The third advantage is versatility. Laser cutters can cut a wide range of materials beyond just sheet metal, including plastics, wood, and other metals. Their CNC systems can be reprogrammed to produce different patterns and designs, providing flexibility in product design.

Lastly, the use of laser cutters results in minimal waste. The precision of the laser beam reduces the amount of off-cut material, leading to more efficient use of raw materials and waste reduction, making it an environmentally friendlier option in manufacturing.

Are there limitations to using a sheet metal laser cutter?

Despite the numerous advantages, there are also some limitations to using a sheet metal laser cutter. One significant limitation is cost. The upfront investment for a laser cutter can be high, making it a less viable option for small businesses or hobbyists. Additionally, the cost of operation and maintenance can be significant, due to the need for cooling systems and regular servicing.

Another limitation is the thickness of the material. While laser cutters are highly effective for thin and medium-thickness materials, they struggle with thicker materials, with the quality and speed of the cut decreasing as material thickness increases.

Finally, there’s the issue of safety. Laser cutters, by their nature, are hazardous if not used correctly. They emit high-intensity light that can cause harm to eyes and skin, necessitating the use of specific safety equipment and precautions, adding another layer of complexity to their operation.

Which materials can be cut using a sheet metal laser cutter?

A sheet metal laser cutter is a versatile piece of equipment capable of cutting a wide array of materials. Primarily, it is designed to cut various types of metals such as stainless steel, mild steel, aluminum, brass, and copper. However, the utility of a laser cutter extends beyond metals. With appropriate settings, lasers can also cut non-metallic materials including wood, plastics, glass, and even certain types of fabrics. It is crucial to note, though, that the effectiveness of the cut depends significantly on the material’s thickness and the power of the laser being used. For instance, hard and thick materials like glass and certain types of metals may require a high-power laser cutter for optimal results.

What are the different types of sheet metal laser cutters?

There are primarily three types of sheet metal laser cutters, each employing a different type of laser beam source: CO2 laser cutters, Fiber laser cutters, and Crystal laser cutters.

CO2 laser cutters use a gas mixture, primarily composed of carbon dioxide, in a tube excited by electricity. These cutters are versatile and capable of cutting non-metallic materials as well as metals, making them suitable for various applications. However, they are relatively large and require more power compared to other types.

Fiber laser cutters, on the other hand, generate their laser beam through optical fibers doped with rare-earth elements. They are known for their efficiency, and offer high speed and precision when cutting metals, but are less effective on non-metal materials.

Crystal laser cutters use nd: YAG (neodymium-doped yttrium aluminum garnet) and nd: YVO (neodymium-doped yttrium orthovanadate) crystals to produce laser beams. While they can cut both metals and non-metals and have a longer operational life than CO2 lasers, they’re more expensive and have a shorter service life compared to fiber lasers.

Choosing the right type of laser cutter depends on several factors including the material to be cut, its thickness, the desired precision, and budget constraints.

Key Features of Sheet Metal Laser Cutting Machines

When evaluating sheet metal laser-cutting machines, there are several key features to consider:

- Power output: The power output of the laser determines the cutting speed and the thickness of the material that can be cut. Higher power outputs allow for faster cutting speeds and the ability to cut thicker materials.

- Cutting speed: The speed at which the machine can cut the material is crucial, particularly in an industrial setting where efficiency and productivity are key.

- Precision: High-precision cutting is essential for detailed work and accurate results. A machine with high precision will produce less waste material and require less finishing work.

- Ease of use: Some machines come with software that makes them easier to use and program, reducing the learning curve and allowing for more efficient operation.

- Service life & maintenance: The service life of the laser source and the maintenance requirements of the machine can significantly impact the overall cost and uptime of the machine.

- Versatility: A versatile machine can cut a variety of materials and thicknesses, making it a more flexible option for different projects.

Remember, choosing the right sheet metal laser-cutting machine will largely depend on your specific needs and constraints.

What role does the laser source play in sheet metal laser-cutting machines?

The laser source is a pivotal component of a sheet metal laser cutting machine since it generates the laser beam used for cutting. Its quality and performance significantly influence the capacity of the machine to cut through materials with precision and speed. A high-quality laser source provides a consistent, focused beam that enables the machine to cut with accuracy, reducing waste and enhancing efficiency. It also affects the machine’s maintenance needs as a longer-lasting laser source means reduced downtime for replacements and repairs. Furthermore, the power output of the laser source dictates the thickness of the material that could be cut, and the speed at which the cutting can be done. Thus, when considering a laser-cutting machine, attention should be given to the type, quality, and power output of the laser source.

How does the cutting process work in sheet metal laser cutting machines?

The cutting process in sheet metal laser cutting machines involves several precisely controlled steps. First, the design to be cut is programmed into the machine’s control system. This digital design guides the laser beam’s path for cutting. The laser source then generates a high-powered, focused laser beam that is directed onto the sheet metal surface through a series of mirrors and a focusing lens. The intense heat of the laser beam vaporizes the material, resulting in a precise cut. A high-pressure jet of assist gas, typically oxygen or nitrogen, is simultaneously directed at the cut. The gas jet blows away the vaporized metal and any molten material, allowing for a clean cut. This process continues, as the laser beam moves across the material surface, following the programmed design path. The result is a highly accurate cut of the desired shape and size. Thus, the cutting process in a sheet metal laser cutting machine is a complex interaction of light, heat, and force, precisely controlled for optimal results.

What are the different laser power options available for sheet metal laser cutting machines?

Sheet metal laser cutting machines come with a variety of laser power options to accommodate different operational requirements. At the lower end of the spectrum, machines with laser power outputs of 500 to 1000 watts are suitable for cutting thin materials, such as thin gauge steel or aluminum, with good speed and precision. Machines with laser powers between 1500 to 2500 watts offer more versatility, capable of cutting both thinner and somewhat thicker materials, including stainless steel, efficiently. For heavy-duty industrial applications, machines with laser power outputs ranging from 3000 to 6000 watts are preferred. These machines can cut through thick steel plates and other robust materials with ease and speed. However, it is critical to note that as the laser power increases, so do the machine’s operational and maintenance costs. Therefore, users should carefully consider their cutting needs and budget before selecting the appropriate laser power option.

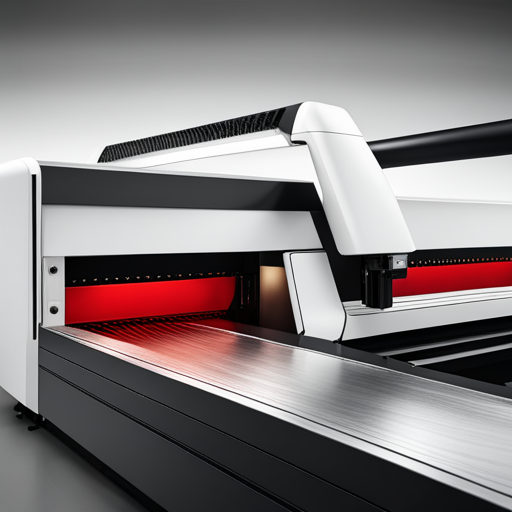

How does the cutting head contribute to the precision of sheet metal laser cutting machines?

The cutting head of a sheet metal laser cutting machine plays a crucial role in ensuring precision in the cutting process. It houses the focusing lens that converges the laser beam to a fine point, facilitating high-precision cuts. The cutting head also contains a nozzle that directs the assist gas, typically oxygen or nitrogen, to the cut zone. This gas serves to eject molten material, reduce heat influence on the surrounding material, and prevent oxidization. Furthermore, advanced cutting heads often feature adaptive optics to adjust the focus dynamically for varying material thicknesses or automated focal length control systems for maintaining optimal focus, which further enhances precision. Lastly, the stability and accuracy of the cutting head’s movement, typically controlled by high-precision servo motors, have a direct impact on the cut quality and precision.

What are the speed and quality factors associated with sheet metal laser cutting machines?

The speed and quality of cuts achieved with sheet metal laser cutting machines are influenced by several factors, including the power of the laser, the type and thickness of the material, and the complexity of the cut. Higher-power lasers can cut more quickly through thicker materials, but the speed must be appropriately balanced with the cut quality. For instance, cutting too fast can lead to a less precise cut, adversely affecting the quality.

The type of material also plays a significant role. Metals like aluminum and steel can be cut faster than hard materials such as titanium. Similarly, thinner materials can be cut faster than thicker ones. However, the speed must be managed to prevent heat buildup, which can distort the material and degrade cut quality.

Furthermore, the complexity of the cut can influence speed and quality. Straight cuts are typically faster and cleaner than complex or intricate cuts, which require slower speeds to maintain precision.

Lastly, the skill and experience of the operator also factor into achieving optimal speed and quality. An experienced operator can make adjustments based on the material, job requirements, and machine capabilities to achieve the best possible balance of speed and quality.

Applications and Industries Using Sheet Metal Laser Cutters

Sheet metal laser cutters find widespread application across a multitude of industries due to their precision and efficiency.

Automotive Industry

January 29, 2024

In the automotive industry, these machines are employed for cutting complex parts and intricate patterns for components such as engine parts, car bodies, and interior elements. The precision of laser cutters is crucial in maintaining the strict tolerances required in automotive manufacturing.

Aerospace Industry

In the aerospace sector, laser cutters are used to fabricate components of aircraft and spacecraft. Given the premium placed on weight reduction in this sector, the ability of laser cutters to cut exact shapes from high-strength, lightweight materials is indispensable.

Electronics Industry

The electronics industry uses laser cutters to accurately cut thin sheets of metal used in components like circuit boards, connectors, and casings. The precision offered by these machines ensures the functionality and reliability of electronic products.

Construction Industry

In the construction sector, laser cutters are used for cutting structural elements, panels, and HVAC components. The speed and accuracy of these machines contribute to increased productivity and cost-effectiveness in construction projects.

How are sheet metal laser cutters employed in the automotive industry?

In the automotive industry, sheet metal laser cutters are commonly used to create intricate parts with high precision. They are especially significant in the production of components such as exhaust systems, transmission parts, and car body elements. Laser cutters can create complex geometries and patterns in sheet metal, resulting in parts that conform to exact design specifications. Additionally, they play a crucial role in prototyping, allowing engineers to produce sample parts quickly and cost-effectively for testing and validation. The flexibility of laser cutting technology also supports customization in car manufacturing, enabling the production of custom parts efficiently and with high precision.

What role do sheet metal laser cutters play in the aerospace industry?

In the aerospace industry, sheet metal laser cutters play an integral role in the manufacturing and maintenance of aircraft components. These machines create precise cuts on a variety of materials, including high-strength alloys, necessary for the construction of critical aircraft parts. The high precision of laser cutters ensures the components fit together seamlessly, which is vital for maintaining the structural integrity and safety of the aircraft. Laser cutters also allow for the rapid prototyping of new part designs, facilitating innovation and efficiency in aerospace engineering. Furthermore, the ability of laser cutters to create intricate design patterns helps in reducing the weight of components, a critical factor in the aerospace industry.

What are some common applications of sheet metal laser cutters in the manufacturing sector?

In the manufacturing sector, sheet metal laser cutters have a wide range of applications. They are commonly employed in the production of HVAC components, such as ductwork and vents, where precision and efficiency are paramount. These machines are also used in the fabrication of machinery and equipment parts, creating components with tight tolerances and complex shapes. Additionally, in the electronics industry, laser cutters are instrumental in producing precision parts for devices, such as computer chassis and electronic enclosures. In the medical technology field, laser cutters play a significant role in manufacturing medical devices and instruments that require accurate cutting and shaping. Lastly, in the construction industry, laser cutters contribute to the production of building materials and architectural elements, offering advantages in speed, precision, and repeatability.

How do sheet metal laser cutters benefit the electronics industry?

Sheet metal laser cutters provide invaluable benefits to the electronics industry. They enable the precise and accurate cutting of intricate shapes and designs, essential in creating components for electronic devices. By ensuring high levels of precision, these cutters aid in reducing waste and improving overall efficiency in manufacturing processes. Moreover, laser cutters can handle various materials, including metal, plastic, and ceramics, commonly used in the electronics industry. This versatility makes them an indispensable tool for creating components like printed circuit boards, semiconductor devices, and casings for various electronic devices. Furthermore, their capability for rapid prototyping accelerates the design and development process, contributing significantly to shorter product development cycles in this fast-paced industry.

What are the advantages of using sheet metal laser cutters in architectural applications?

Sheet metal laser cutters offer several strategic advantages in architectural applications. The foremost is precision. The high level of accuracy provided by laser cutters allows for intricate designs to be executed flawlessly, which is crucial in applications such as decorative metalwork or precision-cut structural components. This precision also reduces waste, driving cost-effectiveness. Additionally, laser cutters can handle a wide variety of materials commonly used in architecture, from metals to glass and plastics, rendering them a versatile tool. Furthermore, laser cutters provide excellent repeatability, ensuring that every cut, even for large-scale production, maintains the same level of precision and quality. Finally, the speed and efficiency of laser cutters enable rapid prototyping and faster production times, making them invaluable in today’s fast-paced construction industry where time is often a critical factor.

Comparing Fiber Laser and CO2 Laser Cutting Machines

When comparing Fiber Laser and CO2 Laser Cutting Machines, several factors come into play. Firstly, Fiber Lasers tend to be more efficient in terms of operational costs and energy use. They offer a higher electrical efficiency and need less maintenance than CO2 lasers. In terms of performance, Fiber Lasers excel at cutting thin material types and can cut at a faster rate, significantly reducing production time. CO2 Lasers, on the other hand, are better suited for thicker material applications, providing superior edge quality in thicker materials compared to Fiber Lasers. However, they are slower and require more maintenance, increasing their operational costs. It’s also worth noting that Fiber Lasers have a longer lifespan compared to CO2 lasers, thus providing a better return on investment in the long term. The choice between Fiber and CO2 Laser Cutting Machines ultimately hinges on the specific needs and objectives of the operation.

What are the primary differences between fiber laser and CO2 laser cutting machines?

The primary differences between Fiber Laser and CO2 Laser Cutting Machines lie in their operational efficiency, performance, maintenance requirements, and lifespan. Fiber Lasers are more efficient, requiring less energy and maintenance, and they excel at cutting thin materials at a faster rate. Conversely, CO2 Lasers are better for thicker materials, providing superior edge quality, but they operate at a slower pace and require more maintenance. Additionally, Fiber Lasers have a longer lifespan than CO2 Lasers, providing a better return on investment in the long run. The decision between the two types of laser cutting machines should be based on the specific operational needs and objectives.

How do fiber laser cutting machines perform in comparison to CO2 laser cutting machines?

In terms of performance, Fiber Laser Cutting Machines often outperform CO2 Lasers in several key areas. Firstly, they are highly efficient, requiring less energy to operate and therefore reducing overall operational costs. Secondly, they excel at cutting thin materials, able to do so at a faster rate than CO2 lasers, which increases productivity and reduces turnaround time. However, when it comes to cutting thicker materials, CO2 lasers tend to provide superior edge quality. It’s important to note that Fiber Lasers require less maintenance and have a longer lifespan than CO2 Lasers. This not only minimizes downtime for maintenance but also contributes to a more favorable return on investment over the long term. Therefore, the performance comparison between Fiber and CO2 Laser Cutting Machines will depend largely on the specific operational needs and objectives.

What are the specific advantages of using a fiber laser cutting machine for sheet metal cutting?

Fiber laser cutting machines present several advantages specifically for sheet metal cutting. They boast superior precision and speed, especially for thin sheet metal, compared to traditional cutting methods. The high-energy beam of fiber lasers allows for cleaner, more precise cuts, reducing the need for finishing processes. They are also known for their efficiency and low operational cost, as they consume less energy and require less maintenance due to their solid-state nature. Furthermore, fiber lasers provide excellent beam quality and a smaller focus diameter, resulting in smaller kerf width which enables precise cutting of intricate designs. Lastly, fiber laser cutting machines are more capable of handling reflective materials like aluminum, brass, or copper, which often pose challenges to other laser types. The ability to effectively cut reflective materials widens the range of applications for fiber lasers in the realm of sheet metal cutting.

Are there any limitations associated with using CO2 laser cutting machines for sheet metal cutting?

Yes, there are a few limitations associated with using CO2 laser cutting machines for sheet metal cutting. Firstly, CO2 lasers tend to struggle with cutting reflective materials like brass, copper, and aluminum as these materials can reflect the laser beam, potentially leading to damage to the machine. Secondly, they generally consume more power and require more maintenance than their fiber laser counterparts, leading to higher operational costs. Moreover, they may not deliver the same level of precision as fiber lasers, especially when dealing with very thin sheet metals. Their larger focus diameter results in a larger kerf width which may not be suitable for intricate designs. Lastly, the speed of cutting with CO2 lasers can be slower than fiber lasers, making them less efficient for large-scale production.

Which industries favor fiber laser-cutting machines over CO2 laser-cutting machines for sheet metal applications?

Fiber laser cutting machines are favored in industries where precision, efficiency, and versatility are paramount. These include the automotive industry, where they are used for cutting complex components and parts with high precision. The aerospace industry also extensively uses fiber lasers due to their ability to deal with lightweight, reflective materials such as aluminum alloys. In the medical device manufacturing sector, fiber lasers facilitate the precise cutting needed for intricate devices. Additionally, the electronics industry favors fiber lasers for their ability to accurately cut small, complex components. Lastly, the jewelry industry appreciates fiber lasers for their ability to handle intricate designs and precious metals.

Factors to Consider When Choosing a Sheet Metal Laser Cutter

When choosing a sheet metal laser cutter, several factors need to be considered. First, one should take into account the Type of Laser. As discussed, fiber lasers and CO2 lasers have different properties, making them suitable for different applications. The Material Type and Thickness of the sheet metal being cut is also a crucial factor. For instance, fiber lasers are better equipped for cutting reflective materials and thin sheets. Cutting precision is another important consideration, especially for industries that require high-precision cuts like the aerospace and medical device manufacturing sectors. Operational Costs should also be taken into account. This includes not only the initial cost of the machine but also running costs, maintenance expenses, and energy consumption. Lastly, the Production Speed and Machine Versatility are worth considering, particularly for high-volume manufacturers. These factors will help guide you to a suitable sheet metal laser cutter for your needs.

What factors should be considered when determining the ideal laser power for a sheet metal laser cutter?

Determining the ideal laser power for a sheet metal laser cutter entails a careful evaluation of several factors. The Material Type and Thickness play a crucial role, as denser and thicker materials typically require a higher-power laser for effective cutting. The Cutting Speed also influences the power choice – high-speed cutting demands higher power to maintain the cutting efficiency. Furthermore, the Cut Quality desired affects the decision – higher power can lead to smoother edges, but excessive power might result in material deformation. The Operational Costs should also be considered since higher-power lasers consume more energy and may have higher maintenance costs. Lastly, the Production Volume can impact the decision – if large-scale production is involved, a higher-powered laser may be necessary to maintain the efficiency and speed of the process.

How important is the cutting speed when selecting a sheet metal laser cutter?

Cutting speed is a critical factor when selecting a sheet metal laser cutter. It directly impacts the efficiency and productivity of manufacturing operations. A higher cutting speed enables rapid processing of workpieces, reducing the time per unit and thus allowing for higher volume production. It’s a crucial parameter for high-volume manufacturers where time and productivity are of the essence. However, it’s important to balance cutting speed with cut quality — faster speeds can sometimes lead to rougher finishes. Hence, an optimal cutting speed maintains a balance between efficiency and quality. Furthermore, the cutting speed can affect the operational cost, as faster cutting speeds may require more powerful lasers with higher energy consumption and maintenance costs. Therefore, the cutting speed’s importance cannot be overstated in the selection of a sheet metal laser cutter.

What role does the type of laser source play in the selection of a sheet metal laser cutter?

The type of laser source plays a significant role in the selection of a sheet metal laser cutter. There are primarily two types of laser sources used in sheet metal cutting – CO2 lasers and fiber lasers. CO2 lasers have been traditionally used for many years and are known for their excellent cut quality and high-speed cutting on materials like plastic, wood, and other non-metallic materials. However, they are more expensive to maintain and operate due to their higher energy consumption and need for regular mirror cleaning.

On the other hand, fiber lasers are more modern and have several advantages over CO2 lasers. They are highly efficient, have low operational and maintenance costs, and provide high-speed cutting on metallic materials. Their energy consumption is lower than CO2 lasers, making them a more environmentally friendly option. Also, fiber lasers have a smaller focal diameter, resulting in a thinner kerf width and more precise cuts. However, they may not perform as well on non-metallic materials. Therefore, the choice between CO2 and fiber lasers ultimately depends on the specific requirements of your cutting tasks, such as the type of materials you are working with and the desired cut quality and speed.

How does the size and type of material impact the choice of a sheet metal laser cutter?

The size and type of material significantly impact the choice of a sheet metal laser cutter. First, the size of the material determines the working area required for the laser cutter. A machine with a larger bed size would be necessary for cutting large sheets of metal, while a smaller bed size would suffice for smaller materials. Second, the type of material influences the laser source and the power required. For instance, thicker and harder materials like stainless steel or aluminum demand a laser cutter with higher power output for effective cutting. Additionally, different materials react differently to specific wavelengths of the laser source. While CO2 lasers are excellent for cutting non-metallic materials, fiber lasers are more effective for cutting metals. Hence, understanding the size and type of the material you aim to cut is crucial in selecting the appropriate sheet metal laser cutter.

What are the primary cutting system features to evaluate when choosing a sheet metal laser cutter?

When choosing a sheet metal laser cutter, several primary cutting system features should be evaluated. The power output is a crucial factor as it directly affects the cutter’s ability to cut through different materials and thicknesses. The machine’s speed and efficiency of cutting are also important considerations, as they impact the productivity and turnaround times of projects. Furthermore, accuracy and precision are vital for ensuring high-quality cuts, especially for detailed designs. The system’s software and control interface should also be user-friendly and capable of integrating with your existing systems. Finally, consider the machine’s maintenance needs, durability, and service life, as these factors directly impact the total cost of ownership.

Frequently Asked Questions

Q: How does a laser metal cutter work?

A: A laser metal cutter works by focusing a laser beam onto the surface of the metal sheet, which melts, burns, or vaporizes the material, creating a clean and precise cut.

Q: What types of metals can be cut with a laser metal cutting machine?

A: Laser metal cutting machines can cut various types of metals, including stainless steel, aluminum, copper, and carbon steel, among others.

Q: What are the advantages of using a laser metal cutter?

A: Some advantages of using a laser metal cutter include high precision, minimal material wastage, fast cutting speeds, and the ability to cut complex shapes with ease.

Q: Can a laser metal cutting machine cut metal tubes?

A: Yes, many laser metal cutting machines are equipped to cut metal tubes, providing efficient and precise results for tube-cutting applications.

Q: What is the future of laser metal cutting technology?

A: The future of laser metal cutting technology looks promising, with continued advancements in fiber laser power, CNC capabilities, and integration with automated systems for enhanced efficiency and productivity.

Q: Are laser metal cutting machines suitable for sheet metal fabrication?

A: Yes, laser metal cutting machines are widely used in sheet metal fabrication due to their ability to cut complex shapes and perform high-precision cutting operations.

Q: What are the key components of a fiber laser metal cutting machine?

A: The key components of a fiber laser metal cutting machine include the laser source, cutting head, CNC control system, machine bed, and optical system for delivering the laser beam to the workpiece.

Q: How do fiber laser metal-cutting machines compare to other metal-cutting technologies?

A: Fiber laser metal cutting machines offer several advantages over traditional metal cutting methods, including higher cutting speeds, lower maintenance requirements, and superior cut quality.

Q: What are the typical applications of laser metal cutting machines?

A: Laser metal cutting machines are commonly used for applications such as metal fabrication, automotive parts manufacturing, aerospace components, and general metalworking processes.

References

- The Fabricator: A comprehensive online article that discusses the technical aspects of laser cutting along with its applications in the metal fabrication industry.

- Laser Cutting Process Overview – SME: An overview of the laser cutting process from the Society of Manufacturing Engineers, offering technical insight into the operations and mechanisms of laser cutters.

- Laser Cutting Systems – Sci Direct: An academic source that provides in-depth research on the science and technology behind laser cutting systems.

- Technical Report – Illinois.edu: This technical report from the University of Illinois delves into the physics and engineering of laser cutting, providing a detailed analysis of laser cutters.

- Bystronic Laser Cutting Guide: A manufacturer’s guide that provides information on operating a specific model of a laser cutter, which would be beneficial for users.

- Laser Cutting – OSA Publishing: An academic journal article discussing advanced techniques and recent developments in laser cutting technology.

- Thomas Net – Understanding Laser Cutting: An online article providing a detailed explanation of the tolerances of laser cutting.

- Laser Cutting Technology – ResearchGate: A research paper detailing the laser cutting technology including the process, benefits, and limitations.

- TRUMPF Laser Cutting Handbook: A handbook from a laser cutting machine manufacturer, offering comprehensive instructions and guidelines on using their machines.

- Laser Cutting Blog – Boss Laser: A series of blog posts from Boss Laser, a manufacturer of laser cutting machines, detailing different aspects of laser cutting technology.

Recommended Reading: CNC Knife Cutting Machine