What is Acrylic and Its Properties?

Acrylic, also known as Poly(methyl methacrylate) or PMMA, is a transparent thermoplastic often used as a lightweight or shatter-resistant alternative to glass. Its optical clarity, high tensile strength, and weather-resistant properties make it ideal for a variety of applications. Acrylic is also characterized by its ability to be sanded and buffed to a glossy finish, lending itself to aesthetic uses. The material exhibits low water absorption, good electrical resistivity, and fair tensile strength. However, due to its brittle nature, acrylic can be susceptible to cracking or shattering under extreme stress or at lower temperatures.

Understanding the Composition of Acrylic

Acrylic, chemically represented as (C5O2H8)n, is a polymer of methyl methacrylate (MMA). Its molecular structure comprises a long chain of polymers, with each polymer consisting of repeating units of methyl methacrylate. MMA in its monomer state is a colorless and transparent fluid that polymerizes easily to form acrylic. The polymerization process involves the use of catalysts, typically organic peroxide compounds, and heat to trigger a reaction where multiple MMA molecules link together to form long polymer chains. This process creates a solid, translucent material known for its robustness and clarity.

Different Types of Acrylic for Laser Cutting

In terms of laser cutting, it’s crucial to understand that acrylic comes in two primary types – cast and extruded – each with its unique characteristics and benefits.

- Cast Acrylic: Also known as cell-cast acrylic, this type is created through a process that involves pouring the liquid acrylic into a mold. This method allows for greater thickness consistency and offers superior optical clarity. Cast acrylic is highly recommended for laser cutting due to its high-quality cutting edges and minimal heat impact area.

- Extruded Acrylic: Extruded or “continuous cast” acrylic is made by pushing the acrylic mass through a form while applying heat, which makes the production process faster and cheaper. However, the heat distribution during laser cutting is less optimal, which could lead to more significant heat impact areas and potentially less sharp cutting edges compared to cast acrylic.

Both types can be successfully cut with a laser, but understanding the subtle differences between them is essential for achieving optimal results.

Factors Affecting Acrylic Laser Cutting

Several factors can impact the quality of acrylic laser cutting:

- Laser Power: The laser’s strength plays a pivotal role in the cutting process. A higher-power laser yields cleaner cuts, but too much power can lead to the melting or burning of the material.

- Cutting Speed: The speed at which the laser moves can also affect the cutting quality. A slower speed may result in melting, while a too-high speed may lead to an incomplete cut.

- Material Thickness: The thickness of the acrylic significantly influences the laser’s effectiveness. Thicker materials require slower cutting speeds and higher laser power.

- Lens Focal Length: The focal length of the lens in the laser cutting machine can affect the quality of the cut. A smaller focal length results in a smaller spot size, providing a more precise cut.

- Air Assist: Using air assist can help reduce the risk of the material catching fire and can improve the quality of the cut by blowing away the heat and combustible gases.

Understanding and adjusting these factors can help achieve the cleanest and most precise acrylic laser cuts.

Importance of Thickness and Laser Power in Acrylic Cutting

The importance of material thickness and laser power can’t be overstated in the realm of acrylic cutting. These two elements directly influence the quality and precision of the end product. Thicker acrylic sheets necessitate a slower cutting speed and higher laser power to ensure a clean, unbroken cut. Conversely, lower thickness requires less power and faster speeds to prevent melting or burning of the material.

Laser power also plays a significant role in determining the clarity of the edges post-cutting. Higher laser power results in cleaner, smoother edges with reduced risk of chipping or melting. However, excessively high power can lead to the undesirable melting of the acrylic. Therefore, it’s crucial to balance these two factors – thickness and laser power – to achieve optimum cutting results. This balance ensures the efficiency of the process and the quality of the final product, underlining its importance in the realm of acrylic cutting.

How to Achieve Clean and Flame-Polished Cut Edges on Acrylic

To achieve clean and flame-polished cut edges on acrylic, several steps need to be followed diligently.

- Set the Correct Parameters: Adjust the laser power, speed, and frequency based on the thickness of the acrylic sheet. A solid understanding of how these parameters interact is crucial for achieving a polished cut.

- Use Air Assist: Always use air assist when cutting acrylic. It helps blow away heat and combustible gases, reducing the risk of the material catching fire and enhancing the quality of the cut.

- Post-Cutting Air Blast: After cutting, use a high-pressure air blast to remove any remaining dust or debris from the edges.

- Flame Polishing: Finally, flame polish the cut edges with a propane or butane torch to give them a glossy finish. Ensure that the flame is blue and make the paste quickly to avoid burning or melting the acrylic.

By carefully adhering to these steps, clean and flame-polished cut edges on acrylic can be achieved, enhancing the aesthetic and functional quality of the finished product.

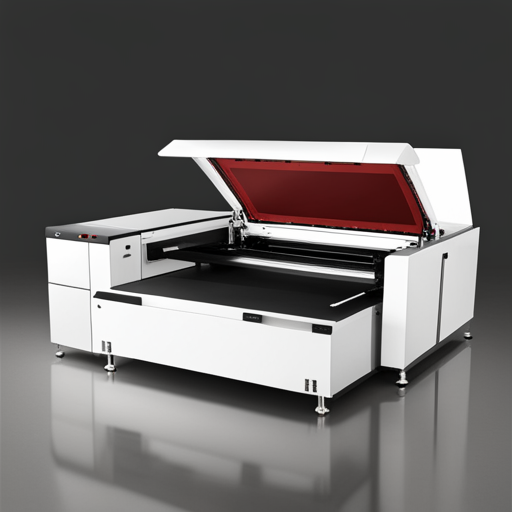

Choosing the Right Laser Cutter for Acrylic

When selecting a laser cutter for acrylic, it’s important to consider several key factors. Firstly, the power of the laser cutter is vital – a higher-power laser can cut through thicker acrylic sheets but, as mentioned earlier, excessively high power may lead to melting. Secondly, consider the cutting speed of the machine, as a faster cutter reduces job time, increasing productivity. Thirdly, evaluate the precision and accuracy of the cutter – for detailed designs, a laser cutter with high precision is essential. Fourthly, evaluate the machine’s safety features. Look for features like air assist, cooling system, and emergency stop functions. Lastly, consider the machine’s compatibility with different software – a device compatible with several design software offers more flexibility in creating designs. By taking these factors into account, selecting the right laser cutter for acrylic becomes an easier and more precise task.

Key Features to Look for in an Acrylic Laser Cutting Machine

- Power Output: The power output of the laser cutting machine plays a crucial role in determining the thickness of the acrylic that can be cut. Machines with a higher power output can handle thicker acrylic sheets. However, be wary of excessive power as it could lead to melting or damage of the material.

- Cutting Speed: A machine with a high cutting speed can complete tasks more efficiently, hence, improving workflow and productivity. Speed should, however, not compromise the quality of the cut.

- Precision and Accuracy: For intricate and detailed designs, precision and accuracy are paramount. The machine should be able to follow the design patterns closely and make clean, precise cuts.

- Safety Features: Safety should never be compromised. Look for machines that include safety features such as air assist, cooling systems, and emergency stop functions to ensure safe operation.

- Software Compatibility: The machine’s compatibility with different design software provides flexibility in creating designs. Machines that support a range of software can handle various file formats, making them more adaptable to different project requirements.

- Ease of Use and Maintenance: The machine should be user-friendly with intuitive controls and easy setup. Additionally, it should be easy to maintain, with readily available replacement parts and responsive customer service.

By evaluating these features, you can select a laser-cutting machine that fits your needs and provides the best value for your investment.

Understanding Co2 and Diode Laser Technology for Acrylic Cutting

CO2 and Diode lasers represent two distinct technologies used for acrylic cutting, each offering unique capabilities and advantages.

CO2 lasers, widely recognized for their versatility and efficiency, employ a gas mixture (predominantly composed of carbon dioxide) electrically stimulated to produce a high-energy light beam. This beam, when focused on the acrylic surface, heats, melts, and vaporizes the targeted material, enabling precise and clean cuts. CO2 lasers excel in cutting thicker acrylic sheets, and their high power output makes them ideal for large-scale industrial applications.

On the other hand, Diode lasers, also known as semiconductor lasers, generate laser beams through the stimulated emission of radiative energy. These lasers are typically compact, efficient, and boast a longer operational lifespan. While they may lack the raw cutting power of CO2 lasers, Diode lasers are particularly effective for engraving intricate designs or cutting thinner acrylic materials.

In conclusion, the choice between CO2 and Diode lasers should be dictated by the specific requirements of your project. Consider factors such as the thickness of the acrylic, the complexity of the design, and the scale of operation when deciding on the optimal laser technology.

Optimizing Cutting Speed and Quality for Acrylic with Laser Machines

Optimizing cutting speed and quality when using laser machines for acrylic involves a delicate balance of several factors. A critical aspect to consider is the laser’s power setting, which should be tailored to the thickness of the acrylic to ensure smooth, clean cuts. Higher power settings are suitable for thicker materials, while lower settings are ideal for thinner ones.

Accuracy is another vital element in the optimization process. The use of a laser beam with the optimal diameter will ensure precise cuts and minimal waste. A smaller beam diameter is preferable for intricate designs, while a larger diameter is beneficial for straight, broad cuts.

Lastly, the speed at which the laser moves across the acrylic plays a pivotal role in influencing the cut’s quality and appearance. Faster speeds may reduce the total cutting time but might result in incomplete cuts or a rough finish. Conversely, slower speeds can produce cleaner, more polished cuts, but increase the operation time. Therefore, it is crucial to balance speed and quality, taking into account the nature of the project and the desired outcome.

Therefore, by carefully managing these parameters – power, accuracy, and speed – you can efficiently optimize the cutting process, maximizing productivity while ensuring an excellent finish on the acrylic material.

Benefits of Using Fiber Lasers for Acrylic Cutting

Fiber lasers offer numerous advantages for acrylic cutting, which are key to enhancing productivity and output quality:

- High Precision: Fiber lasers possess an exceptionally small focal diameter, enabling the creation of highly detailed and precise cuts in the acrylic.

- Efficiency: They consume less power compared to other laser types, such as CO2 lasers, making them more energy-efficient.

- Low Maintenance: Fiber lasers have few moving parts and no consumables, reducing the frequency and cost of maintenance.

- Speed: These lasers operate at high speeds, significantly reducing the cutting time and increasing throughput.

- Versatility: Fiber lasers can cut a variety of materials, not limited to acrylic, providing flexibility for different projects.

- Safety: The beam delivery system in fiber lasers is fully enclosed, minimizing the risk of accidental exposure to the laser beam.

- Quality: They produce clean, polished cuts, minimizing the need for post-processing.

- Durability: Fiber lasers have a long operational life, making them a cost-effective choice for long-term use.

By selecting a fiber laser for acrylic cutting, businesses can achieve superior results, saving time and reducing costs.

Tips for Engraving and Cutting Acrylic Sheets with Precision

When it comes to engraving and cutting acrylic sheets with precision, certain best practices can significantly enhance the quality of the end product:

- Choose the Right Laser Power: The laser power selected should be appropriate for the thickness of the acrylic sheet. Higher power is typically required for thicker sheets.

- Set the Correct Speed: Slower speeds result in deeper cuts and darker engravings. Find the right balance between speed and the desired outcome.

- Perform Regular Maintenance: Regular cleaning and maintenance of the laser cutter ensure its optimal performance and precision.

- Use Air Assist: Air assist helps to reduce heat and combustion risks, providing a cleaner cut.

- Quality of Acrylic: Use high-quality acrylic for a smoother cut and better engraving results. Lower-quality materials can result in rough edges and poor engraving visibility.

- Protection: Always protect the un-engraved area to avoid any damage or unwanted marks.

Implementing these tips can enhance the precision of your acrylic cutting and engraving, ensuring a high-quality result while optimizing the efficiency of the process.

The Laser Cutting Process for Acrylic

The laser cutting process for acrylic begins by creating a digital design in graphic software, which serves as the guide for the laser cutter. The acrylic sheet is then placed on the cutting bed of the laser machine. Once the settings are appropriately adjusted for the thickness and type of acrylic, the process begins. The laser beam, guided by the digital design, moves across the surface of the acrylic, heating it to a high temperature. This intense heat vaporizes the material, resulting in a precise and clean cut. For engraving, the laser beam intensity is lowered to merely remove the surface of the acrylic, creating the desired design without cutting through the material. The speed, power, and focus of the laser beam can be adjusted to achieve various results, offering great versatility. Cooling and air assist mechanisms are used to prevent overheating and combustion, ensuring a clean and high-quality finish.

Step-by-Step Guide to Laser Cutting Acrylic Material

- Design Preparation: Begin by preparing your design in graphic design software compatible with your laser cutter. Make sure to convert your design into vector format for precise cutting and engraving.

- Material Setup: Place the acrylic sheet on the cutting bed of the laser machine. Ensure it’s securely fixed to avoid any movement during the process.

- Adjust Settings: Configure the settings of the laser machine according to the thickness and type of acrylic. Adjust the power, speed, and focus of the laser beam for optimal results.

- Initiate Cutting: Start the process. The laser, guided by your design, will move across the surface of the acrylic, vaporizing the material and creating a precise cut.

- Engraving (if required): If your design involves engraving, reduce the intensity of the laser beam. This will remove only the surface of the acrylic, leaving the desired design without cutting through.

- Cooling and Air Assist: Make sure to utilize cooling and air assist mechanisms during the process to prevent overheating and combustion.

- Final Inspection: After completion, examine the acrylic for any imperfections. If all is well, your laser-cut acrylic piece is ready for use.

Benefits of Using a Laser for Engraving on Acrylic

Laser engraving on acrylic offers numerous benefits:

- Precision: Laser engraving offers unmatched precision, allowing for intricate designs with very fine details. It performs reliably even on complex shapes and sizes.

- Non-Contact Method: Being a non-contact process, laser engraving eliminates the risk of damaging or distorting the acrylic material during the engraving process.

- High-Speed Operation: Laser machines can engrave designs at a much faster pace compared to traditional methods. This results in increased productivity and efficiency.

- Consistency: Lasers provide consistent results, making them suitable for both one-off productions and large-scale manufacturing.

- Cost-Effective: Lasers have lower operating costs, and due to their precision, there is less waste material produced.

These advantages make laser engraving an ideal choice for working with acrylic materials.

Ensuring High-Quality Output with Laser-Cut Acrylic Projects

To ensure high-quality output with laser-cut acrylic projects, a few key steps should be meticulously followed:

- Material Selection: Choose high-quality acrylic with a consistent thickness for optimal results. Imperfections in the material can lead to inconsistent engraving and cutting.

- Optimal Parameters: Adjust the settings of the laser machine for the specific type of acrylic you’re working with. The parameters should be fine-tuned to achieve the desired depth of engraving and smooth cutting edges.

- Proper Maintenance: Regular maintenance of the laser machine is crucial to maintain its performance and prolong its lifespan. This includes cleaning the lens, checking the alignment, and ensuring the cooling system is functioning properly.

- Post-Processing: After the cutting and engraving process, the acrylic piece should be cleaned to remove any residues. It can then be polished or finished as required to enhance its appearance.

Adhering to these best practices will result in high-quality laser-cut acrylic pieces that are both functional and aesthetically appealing.

Optimizing Laser Parameters for Different Types of Acrylic

When optimizing laser parameters for different types of acrylic, understanding the composition and thickness of the material is critical.

- Extruded Acrylic: This type of acrylic melts easily and requires a lower power setting. For cutting, a higher speed and lower power yield clean edges. For engraving, a high-speed and low-power combination can prevent the material from melting too much.

- Cast Acrylic: Unlike extruded acrylic, cast acrylic is denser and requires a higher power setting for cutting and engraving. It produces a high-contrast, white engraved image ideal for detailed designs.

- Colored Acrylic: The laser parameters for colored acrylic can vary due to the pigments and the transparency of the material. Darker and less transparent materials typically require higher power settings, while lighter and more transparent materials need less power.

Adjusting the speed and power settings of the laser machine according to the type and thickness of the acrylic can enhance the quality of the cut and engraved designs. Always perform a test cut before proceeding with the actual project to ensure the optimal settings are used.

Advanced Techniques for Engraving and Cutting Acrylic Parts

Inverse Engraving

Inverse engraving is a technique that involves engraving the areas around the design instead of the design itself. This method can give a dramatic effect to the engraved design, making it stand out more on the acrylic piece.

3D Engraving

3D engraving is another advanced technique that creates depth in the acrylic by varying the engraving density in different areas of the design. This technique requires a laser machine with 3D engraving capabilities.

Vector Cutting

Vector cutting is a technique that involves cutting along a path or a line in the acrylic. This method is highly precise and is ideal for creating intricate designs or pieces with sharp, exact edges.

Multipass Cutting

Multipass cutting involves making several passes with the laser over the same cut line. This technique can help to achieve a cleaner edge, especially on thicker pieces of acrylic.

Cooling Techniques

Applying a cooling technique can prevent overheating and melting of the acrylic during the cutting or engraving process. One simple method is to use air assist to blow a stream of air at the point where the laser touches the acrylic.

Remember, each of these advanced techniques requires a thorough understanding of the laser machine’s capabilities and settings. Always perform a test run before applying these techniques to the main project.

Tips for Successful Acrylic Laser Cutting and Engraving

- Understand Your Material: Different types and thicknesses of acrylic respond differently to laser cutting and engraving. It is important to understand the properties of the acrylic you are working with to optimize the process.

- Adjust the Power Settings: Depending on the thickness and type of acrylic, the power setting of the laser should be adjusted accordingly. Higher power settings are needed for thicker acrylic, while lower settings can be used for thinner materials.

- Use the Correct Lens: For detailed engraving, use a lens with a shorter focal length. For thicker acrylics or deep engraving, a lens with a longer focal length would be more suitable.

- Ensure Proper Ventilation: Acrylic releases fumes when cut or engraved using a laser. Proper ventilation is necessary to ensure the safety of the operator and the efficiency of the machine.

- Clean the Machine Regularly: Regular cleaning of the laser machine is essential. Accumulated debris can affect the quality of the cuts and engravings, and can also pose potential hazards.

- Use Protective Equipment: Always wear protective eyewear when operating a laser machine. This helps prevent accidental eye injury from reflected laser light.

Remember, always take safety precautions when operating a laser machine, and understand the operation manual thoroughly before starting any project.

Best Practices for Laser Engraving Acrylic Signage

- Prepare the Design: Start with a digital design of the signage considering the final size and detailing. The size of the design should match the size of the acrylic sheet. Ensure to reverse the design if you plan to engrave on the back side of the sheet.

- Choose the Right Acrylic: Cast acrylic is usually preferred over extruded acrylic for laser engraving. It offers a smooth, glass-like edge when cut, and produces a white or frosted look when engraved, which is often more readable.

- Optimize Laser Settings: Adjust the laser’s power, speed, and frequency settings according to the type and thickness of the acrylic. For detailed engravings, a slower speed and higher power setting often yield the best result.

- Use a Masking Material: Apply a masking material to the engraving area. This helps prevent residue from the engraving process from sticking to the surface of the acrylic.

- Clean the Signage: After engraving, clean the signage properly with a soft cloth and a non-abrasive cleaning solution to remove any dust or residues. Avoid aggressive cleaning agents as they can damage the acrylic surface.

- Polish the Edges: If you’re seeking a more finished look, consider flame polishing the edges of the acrylic signage. Be sure to do this in a well-ventilated area and follow all safety procedures.

These best practices should help you achieve high-quality, professional-looking engravings on acrylic signage. Remember to always prioritize safety and take your time to ensure the best results.

Common Challenges Faced in Acrylic Laser Cutting and Solutions

- Heat Damage: Excessive heat during the laser cutting process can lead to unwanted melting or warping of the acrylic. To prevent this, ensure that the power settings are correctly adjusted and consider multiple low-power passes for thicker acrylics instead of a single high-power pass.

- Residue Build-Up: The engraving process can produce residue that, if not properly managed, can affect the clarity and quality of the engraving. Using a masking material, as discussed earlier, can mitigate this issue. After engraving, thorough cleaning with a non-abrasive solution is essential.

- Inconsistent Engraving Depth: If you notice uneven engraving depth, this could be due to an uneven working table or focus issues with the laser. Regularly check the level of your work surface and calibrate the laser’s focus to ensure a consistent engraving depth.

- Cracking or Breaking: If the acrylic cracks or breaks during the process, it might be due to the type of acrylic being used. Cast acrylic is less prone to cracking compared to extruded. Also, ensure your materials are stored properly; incorrect storage can lead to brittleness.

By anticipating and addressing these common challenges, you can further enhance the quality of your acrylic laser cutting and engraving, resulting in a more professional and polished end product.

Maximizing Speed and Power Efficiency in Acrylic Laser Cutting

Achieving the optimal balance between speed and power efficiency in acrylic laser cutting is crucial to delivering superior results. Here are a few strategies to consider:

- Optimize Power Settings: Adjusting the laser power is an effective way to control the speed of cutting. Higher power settings may lead to faster cuts, but they also risk causing heat damage to the acrylic. Experiment with various power levels to find the most efficient one for your specific machine and material thickness.

- Fine-tune the Speed Settings: Similarly, varying the speed settings can influence both the quality of the cut and the efficiency of the process. Slow speeds may lead to cleaner cuts but at the cost of time efficiency. Like power settings, speed should be adjusted according to the thickness of the acrylic and the power of the laser.

- Use Appropriate Lens: The lens used can significantly affect the speed and power efficiency of the laser. A shorter focal length lens allows for faster cutting due to its ability to focus the laser beam to a smaller spot, allowing more power in a concentrated area.

- Regular Maintenance: Regularly cleaning and maintaining the laser cutter can prevent unnecessary slowdowns or stops in the cutting process, thereby enhancing efficiency. This includes cleaning the lens, mirrors, and the work surface, as well as checking the machine for any needed repairs or parts replacement.

By optimizing these factors, you can maximize both speed and power efficiency in acrylic laser cutting, reducing waste and increasing productivity.

Exploring Innovative Applications of Laser-Cut Acrylic in Design and Art

Laser-cut acrylic has found its way into numerous creative domains, revolutionizing the fields of design and art. Architectural Model Building is one such area where precision and intricate detailing offered by laser cutting are indispensable. Architects leverage this technology to create highly accurate and detailed scale models, enabling visual representation of complex structures. In the realm of Jewelry Design, the versatility of acrylic coupled with the precision of laser cutting allows designers to create intricate patterns and unique pieces that were previously challenging to achieve. The signage and Display industry also heavily utilizes laser-cut acrylic for crafting eye-catching signs, logos, and display units that require high levels of precision and detail. Artists have started to explore the potential of laser-cut acrylic in creating Mixed Media Art, where elements of acrylic are combined with various other materials to produce stunning pieces of art. By integrating technology and creativity, these innovative applications of laser-cut acrylic are pushing the boundaries of design and art.

Maintaining Optimum Edge Quality and Clarity in Laser-Cut Acrylic Sheets

The quality of edges and clarity in laser-cut acrylic sheets is of utmost importance for professional results. To maintain optimum edge quality, it’s crucial to use a suitable laser power and speed setting. Higher laser power can result in a smoother edge, but excessive power might lead to melting or damage. A balance must be struck according to the thickness of the acrylic sheet. When it comes to clarity, it’s essential to use a high-quality acrylic that is specifically designed for laser cutting. This ensures a clean, glass-like edge straight off the laser cutter, without the need for flame polishing. Additionally, keeping the laser cutter’s lens clean and using proper exhaust systems can help reduce the deposition of residues on the cut edges, thus enhancing overall clarity. Regular machine maintenance also plays a vital role in maintaining consistent edge quality and clarity. By adhering to these practices, it is possible to achieve high-quality laser-cut acrylic sheets with excellent edge quality and clarity.

Important Considerations for Acrylic Laser Cutting Systems

When selecting a laser cutting system for acrylic, several key factors need to be considered to ensure optimal functionality and results.

- Laser Power: The power of the laser directly affects the cutting speed and the thickness of the material that can be cut. Higher-power lasers can cut thicker materials at a faster rate but may increase the risk of damage to thinner materials.

- Cutting Bed Size: The size of the cutting bed should be adequate for the size of acrylic sheets to be processed. This can vary depending on the specific applications and requirements.

- Air Assist: An air assist feature can help reduce the risk of ignition and improve cut quality by blowing away heat and debris from the cutting area.

- Exhaust System: A good exhaust system is critical in removing the gases and particles produced during the cutting process, which can otherwise affect the quality of the cut and the life of the machine.

- Software Compatibility: The laser cutting system should be compatible with the software you plan on using for design and control. Popular options include Adobe Illustrator, AutoCAD, and CorelDRAW.

By considering these factors, one can ensure the selection of an acrylic laser cutting system that will deliver the desired results consistently.

Understanding the Role of Laser Heads in Acrylic Cutting Precision

The laser head plays a crucial role in determining the precision of cuts when dealing with acrylic materials. The laser head houses the focusing lens, which concentrates the laser beam onto the surface of the acrylic, and the distance between the focusing lens and the material significantly impacts the preciseness of the cut. A shorter focal length provides a smaller focus diameter and hence more precise cuts, but with a reduced cutting thickness. Conversely, a longer focal length allows for a greater cutting thickness but at a compromise on cut precision. Moreover, the quality of the lens itself can also affect the accuracy and quality of the cuts, with high-quality lenses providing better focus and durability. Therefore, when selecting a laser cutting system for acrylic, the type, quality, and focal length of the laser head should be carefully considered to ensure optimal precision and efficiency.

Choosing the Right Laser Processing Parameters for Acrylic Projects

Parameters like power, speed, and frequency are critical in the laser-cutting process of acrylics and greatly influence the output quality.

- Power: This is the energy supplied to the laser beam. Higher power can cut thicker materials but may lead to charring or melting on the edges. For acrylics, it’s advisable to use moderate power to achieve clean cuts.

- Speed: Speed refers to how fast the laser head moves across the material. A slower speed leads to deeper cuts but can cause excessive heat buildup. Finding the right balance between the material thickness and power level is essential.

- Frequency: Frequency adjusts how often the laser pulses per second. A high frequency can lead to smoother cuts but increases the risk of heat damage.

Each project may require different parameter settings, so it’s crucial to test and adjust these parameters for optimal results. Always keep in mind that the goal is to achieve clean, precise cuts without damaging the acrylic material.

Exploring the Potential of Mirrored Acrylic in Laser Engraving

Mirrored acrylic presents unique possibilities in the realm of laser engraving. This type of acrylic is characterized by its reflective surface, similar to that of a conventional mirror, and can be engraved to create intricate designs with a remarkable depth of detail.

One notable advantage of using mirrored acrylic is that the laser engraving process does not penetrate through the reflective coating. Instead, it targets the back surface, maintaining the smooth, reflective front surface intact. This results in a high-contrast, visually appealing finish, as the engraved areas offer a striking contrast against the mirror finish.

Furthermore, mirrored acrylic is available in a variety of colors, expanding design possibilities. However, it is crucial to adjust the laser parameters accurately, as mirrored acrylic can be sensitive to high heat. A lower power setting and slower speed can help manage heat buildup, prevent damage to the material, and ensure precise engraving.

Remember, testing on a small piece of the same material before engraving the actual project can help fine-tune the laser parameters for optimal results. In conclusion, with careful handling and precise settings, mirrored acrylic can be a versatile material for laser engraving, offering endless potential for creative expression.

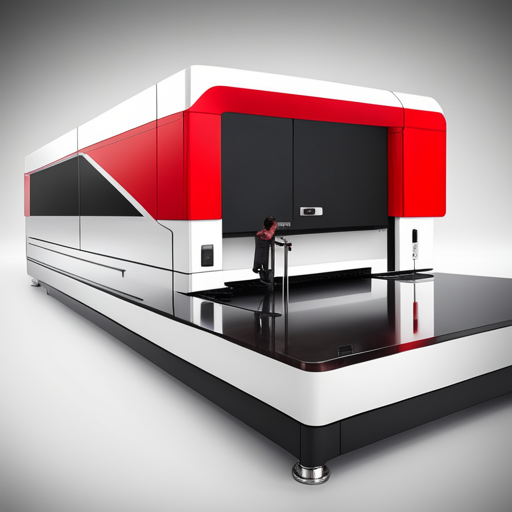

Enhancing Acrylic Cutting Efficiency with Advanced Laser Systems

Advanced laser systems present an innovative solution for enhancing the efficiency of acrylic cutting processes. These systems incorporate cutting-edge technology like high-power lasers and precision control mechanisms, which ensure superior cutting performance. High-power lasers can cut through acrylic quickly and cleanly, reducing the time it takes to complete a project. Meanwhile, precision control mechanisms allow for accurate, finely detailed cuts, minimizing material waste due to errors.

In addition, many modern laser systems feature automated capabilities, such as pre-programmed settings for different types of acrylic and auto-focus features that adjust the beam’s focus depending on the thickness of the material. These features streamline the cutting process and reduce the need for manual adjustments, thereby increasing productivity.

Moreover, advanced laser systems often come with integrated cooling systems that help manage the heat generated during the cutting process, preventing damage to the acrylic material. With their combination of speed, precision, automation, and cooling capabilities, advanced laser systems represent a significant upgrade over traditional cutting methods for acrylic, enhancing efficiency and productivity.

Latest Innovations in Laser Technology for Acrylic Cutting and Engraving

Recent advancements in laser technology for acrylic cutting and engraving have led to the development of machines with greater power, efficiency, and precision. One of these innovations is the introduction of fiber laser technology, which offers a faster cutting speed and lower operating costs compared to traditional CO2 lasers. Fiber lasers are ideal for engraving intricate designs on acrylic due to their high precision and ability to generate smaller spot sizes.

Another groundbreaking innovation is the incorporation of artificial intelligence (AI) and machine learning (ML) in laser systems. These technologies allow the laser systems to adapt and learn from each operation, enhancing precision and efficiency over time. They can also identify potential errors or malfunctions in real time, reducing downtime and increasing productivity.

Lastly, the development of multi-layer systems has revolutionized the acrylic cutting and engraving industry. These systems can operate multiple lasers simultaneously, dramatically reducing the time required to complete large-scale or complex projects. With these cutting-edge technologies, the future of acrylic cutting and engraving appears bright and promising.

Frequently Asked Questions

Q: What is a CO2 laser and how is it used in laser cutting acrylic?

A: A CO2 laser is a type of gas laser that uses carbon dioxide gas as the lasing medium. It is widely used in laser cutting acrylic due to its ability to produce high-power infrared light that can easily cut through acrylic material.

Q: What is cast acrylic and why is it commonly used with laser cutters?

A: Cast acrylic is a type of acrylic material that is manufactured by a casting process, resulting in a higher quality and better optical clarity compared to extruded acrylic. It is commonly used with laser cutters for its superior cut quality and edge finish.

Q: How does a laser engraver differ from a laser cutter when working with acrylic?

A: A laser engraver is specifically designed for creating designs, patterns, or texts on the surface of acrylic material, while a laser cutter is used to precisely cut through acrylic sheets or blocks according to a predetermined design.

Q: What are the main components of cutting equipment used for laser cutting acrylic?

A: The main components of cutting equipment for laser cutting acrylic include the laser source (CO2 laser), cutting table, and control system to precisely control the laser frequency, power, and movement during the cutting process.

Q: How can one achieve better-cut quality when using a laser cutting machine for acrylic?

A: Better cut quality can be achieved by optimizing cutting parameters such as laser power, cutting speed, and focus depth based on the specific characteristics of the acrylic material being used, as well as the desired edge finish and accuracy.

Q: What are the advantages of laser cutting and engraving acrylic for custom applications?

A: Laser cutting and engraving acrylic offer advantages such as precise customization, complex design capabilities, and the ability to create intricate details, making it ideal for custom applications in various industries.

Q: Can clear acrylic be easily cut using a laser cutting machine?

A: Yes, clear acrylic sheets can be easily cut with a laser cutting machine, producing clean edges and precise cuts without the need for additional finishing processes.

Q: Is cast acrylic better suited for laser cutting compared to extruded acrylic?

A: Yes, cast acrylic is better suited for laser cutting due to its higher quality, better edge finish, and the ability to produce superior results with the laser cutting technology.

Q: How can one determine the appropriate amount of laser power to use when cutting acrylic?

A: The appropriate amount of laser power for cutting acrylic can be determined based on factors such as material thickness, desired cutting speed, and the specific properties of the acrylic being cut. It often requires testing and adjustment to determine the optimal power level for desired results.

Q: What are the key considerations for the production of acrylic using a laser cutting machine?

A: Key considerations for the production of acrylic using a laser cutting machine include material selection, design adaptation for laser cutting, optimizing cutting parameters, and ensuring proper ventilation and safety measures during the cutting process.

References

- Laser Cutting of Acrylic – This academic paper on ResearchGate delves into the technical aspects of laser cutting acrylic, making it a valuable resource for those interested in the underlying science and technology.

- The Pros and Cons of Laser Cutting Acrylic – A blog post that discusses the advantages and drawbacks of laser cutting acrylic, providing practical insights into its usage.

- Laser Processing Guide: Acrylic – SPI Lasers, a renowned manufacturer of laser systems, provides a comprehensive guide to laser processing of acrylic on its website.

- How to Laser Engrave Acrylic – Trotec Laser, a leading provider of laser cutters and engravers, offers a step-by-step guide to laser engraving acrylic, making it a go-to resource for practical application.

- Everything You Need To Know About Acrylic (PMMA) – Creative Mechanisms provides an in-depth look at acrylic as a material, which is essential to understanding how it interacts with laser technology.

- The use of artificial intelligence (AI) in laser cutting – An academic article from ScienceDirect explores the role of AI in laser cutting, a key innovation in the field.

- Fiber vs CO2 laser cutting – TWI Global, a research and technology organization, compares fiber and CO2 lasers, helping readers understand the nuances between the two technologies.

- Laser Cutter, Engraver, & Marking Machines | Boss Laser – The official website of Boss Laser, a manufacturer of laser cutters, provides insights into the specifications and capabilities of different laser machines.

- Laser Cutting Acrylic: The Complete Guide – An extensive guide by Ponoko detailing the process of laser cutting acrylic, ideal for those seeking a comprehensive understanding of the topic.

- Acrylic Cutting and Engraving with a Laser Machine – Epilog Laser, a leading laser machine manufacturer, shares an informative article on the process of acrylic cutting and engraving with a laser machine.

Recommended Reading: CNC Knife Cutting Machine