Understanding the Basics of Laser Glass Cutting

Laser glass cutting utilizes focused light beams, harnessed at specific wavelengths, to slice through glass with exceptional precision and minimal material loss. This technique relies on the principle of selective heating, where a precise laser beam is directed toward the glass, causing it to heat up and eventually crack along the intended path. Unlike traditional glass-cutting methods, laser cutting is non-contact, reducing the risk of mechanical stress and damage to the glass. This technology allows for intricate designs and shapes to be cut, making it a preferred choice in industries such as electronics, automotive, and architectural glass production.

Introduction to Laser Technology

Laser, an acronym for Light Amplification by Stimulated Emission of Radiation, is a device that generates a beam of coherent light through an optical amplification process. In essence, a laser is created when the electrons in atoms absorb energy from an electrical current or another laser and become “excited.” The excited electrons move from a lower-energy orbit to a higher-energy orbit around the atom’s nucleus. When they return to their normal or “ground” state, the electrons emit photons – particles of light. These photons are all at the same wavelength and are “coherent,” meaning the peaks and troughs of the light waves are all in lockstep. In contrast, ordinary visible light comprises multiple wavelengths and is not coherent. Laser’s unique properties make it a pivotal tool in numerous applications, including glass-cutting technology.

Benefits of Using Laser for Glass Cutting

Laser-cutting technology offers a multitude of benefits for glass-cutting applications:

- Precision: Laser cutting enables exceptional accuracy, allowing for intricate designs and shapes to be cut with a high degree of precision.

- Non-Contact Method: As a non-contact cutting method, laser reduces the risk of mechanical stress and potential damage to the glass material.

- Efficiency: Laser cutting is a highly efficient process, resulting in minimal material loss and reduced waste.

- Speed: The process is considerably faster than traditional glass-cutting methods, significantly reducing production time.

- Versatility: It can be used to cut a variety of glass types, including tempered glass, laminated glass, and even curved glass.

- Cost-Effective: Although the initial investment may be high, the long-term cost savings in terms of reduced waste, faster production times, and lower maintenance costs make it a cost-effective solution.

- Safety: The non-contact nature of laser cutting greatly reduces the risk of injuries that may occur from manual handling of the glass.

- Automation and Integration: Laser cutting technology can be easily automated and integrated into existing production lines, further enhancing productivity and efficiency.

Types of Glass Suitable for Laser Cutting

Laser-cutting technology can be implemented on various types of glass, each offering its own set of unique characteristics. Here are a few types suitable for laser cutting:

- Flat Glass: This is the most common type of glass and serves as a versatile option for a wide range of applications. With its smooth, planar surface, flat glass is ideally suited for precise laser cutting.

- Tempered Glass: Known for its exceptional strength and safety features, tempered glass can be cut using laser technology. However, it is crucial to cut it before the tempering process, as trying to cut it after could result in the glass shattering.

- Laminated Glass: Composed of layers of glass and interlayer materials, laminated glass can be precisely cut with lasers, promising extraordinary results.

- Borosilicate Glass: This type of glass is highly resistant to heat and chemicals, making it an excellent candidate for laser cutting, particularly in demanding industrial applications.

- Quartz Glass: With its high thermal stability and optical transparency, quartz glass is another type that can be successfully processed using laser cutting.

- Lead Crystal Glass: Known for its high refractive index, lead crystal glass is suitable for laser cutting, allowing for intricate designs and patterns.

Remember, the choice of glass type will significantly affect the quality of the final product, and thus, it should be chosen carefully based on the application and intended use of the glass.

The Process of Laser Glass Cutting

Laser glass cutting is a non-contact process that employs a highly focused laser beam to cut or etch glass. The process begins with the generation of a laser beam, which is then directed onto the glass surface using mirrors. The high-energy laser beam heats the glass surface, causing it to melt and vaporize. The cutting path is controlled by CNC (Computer Numerical Control) programming, ensuring precise, intricate cuts that would be challenging to achieve through traditional methods. The speed, power, and focus of the laser beam can be adjusted based on the type of glass and the desired cut quality. After cutting, the glass edges may require further processing, such as polishing or grinding, to achieve a smooth finish. Laser glass cutting offers many advantages, including high precision, repeatability, speed, and the ability to cut complex shapes with minimal waste. However, it is critical to perform this process under controlled conditions to avoid potential defects, such as thermal stress cracks.

Comparing Laser Cutting with Other Glass Cutting Methods

When comparing laser cutting with other glass cutting methods, several distinct differences arise. Traditional methods of cutting glass, such as mechanical scribing and breaking, can cause micro-cracks, leading to decreased product quality. They also require direct contact with the material, raising the risk of contamination or damage. On the contrary, laser cutting is a non-contact method, virtually eliminating these risks. In addition, mechanical methods often lack the precision of laser cutting, which can easily create complex patterns with high repeatability. However, laser cutting does pose challenges, such as managing the heat-affected zone (HAZ) and ensuring proper ventilation due to the vaporization of the material. Additionally, the cost of laser-cutting equipment is typically higher than traditional tools. Therefore, the choice between these methods depends on several factors, including the required precision, intricacy of the design, budget, and quality standards of the final product.

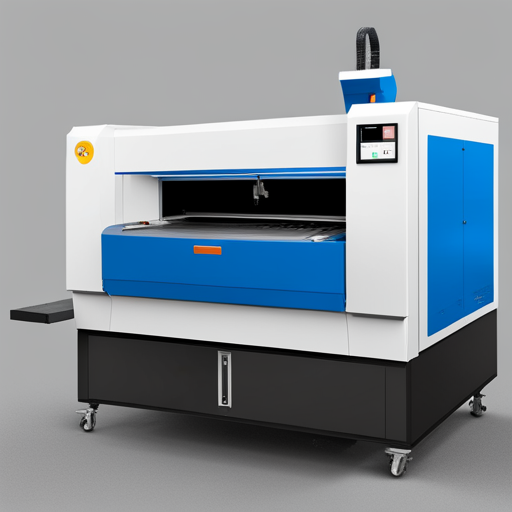

Choosing the Right Laser Glass Cutting Machine

When selecting a laser glass cutting machine, there are several key considerations to ensure it meets your needs. The power of the laser, measured in watts, directly affects the cutting speed and thickness of the glass that can be cut. A higher-wattage laser is more powerful and can cut thicker materials at a faster rate. The size of the working area is another important factor, especially if you plan to cut large pieces of glass. The machine should also have a reliable cooling system to manage the heat generated during the cutting process.

Moreover, consider the software that comes with the machine. It should be user-friendly and have the capability to design and execute complex cutting patterns. Another important consideration is the machine’s precision and repeatability, which are crucial for ensuring consistent quality. Lastly, consider the after-sales service offered by the manufacturer. This includes warranty, availability of spare parts, and technical support.

Remember, the cost of the machine should not be the only deciding factor. It is essential to assess all aspects thoroughly to ensure the machine can meet your operational requirements and quality standards.

Key Features to Consider When Selecting a Laser Cutter

- Power and Speed: The machine’s laser power, measured in watts, is critical. A high-wattage laser can cut thicker materials at a faster pace.

- Working Area: Consider the size of the working area, particularly if you intend to cut large pieces of glass.

- Cooling System: An effective cooling system is essential for managing the heat produced during the cutting process.

- Software: Look for user-friendly software that can design and execute intricate cutting patterns.

- Precision and Repeatability: These are vital for maintaining consistent quality. The machine must be able to reproduce the same cut with high accuracy.

- After-Sales Service: Consider the warranty, availability of spare parts, and technical support offered by the manufacturer.

- Cost: While it’s an essential factor, the cost should not be the sole decision-making criterion. The machine’s ability to meet your operational and quality standards is equally important.

Determining the Optimal Laser Power for Glass Cutting

Determining the optimal laser power for glass cutting is a crucial step in ensuring successful, precise cuts. This depends on multiple factors including the thickness of the glass, the intricacy of the design, and the desired speed of cutting. As a rule of thumb, thicker glass materials require more laser power to cut through, while intricate designs may necessitate lower power to achieve high precision. Moreover, if speed is a priority, higher power settings may be beneficial. However, care must be taken not to use excessively high power as this can lead to cracks or uneven cuts. Experimenting with different power settings on scrap pieces of your material can provide invaluable insights into the optimal laser power for your specific glass-cutting project.

Understanding Laser Cutting Technology for Thick Glass

Laser-cutting technology for thick glass presents unique challenges and considerations. The thickness of the glass necessitates a higher-power laser to effectively cut through the material. However, using a high-power laser can increase the risk of thermal stress, leading to cracks or breakages in the glass. To combat this, certain measures can be taken. Utilizing a continuous wave laser, as opposed to a pulsed laser, can evenly distribute the heat, reducing the risk of thermal damage. Additionally, the use of assisting gas can be beneficial in not only blowing away debris but also cooling the glass and reducing heat-affected zones. Carefully controlling the speed of cutting is also critical, as moving too slowly can cause overheating, but moving too quickly can reduce the cutting quality. Therefore, understanding and optimization of these parameters are essential when employing laser-cutting technology for thick glass.

The Advantages of Using Fiber Laser for Glass Cutting

Fiber lasers present several benefits for glass cutting which stem from their unique design and operation. Firstly, fiber lasers maintain a high degree of precision and accuracy, making them perfect for intricate designs that require careful detail and exactness. Secondly, they offer superior speed compared to traditional methods, significantly reducing the time taken to complete complex projects. The high beam quality of a fiber laser results in a smaller focus diameter, hence achieving a finer cut and better edge quality. Additionally, fiber lasers are known for their energy efficiency, often consuming less power compared to other types of lasers, which leads to reduced operating costs. Lastly, fiber lasers are robust and require minimal maintenance, making them a reliable choice for continuous, industrial applications. As a result, the use of fiber lasers can provide considerable advantages in the realm of glass cutting.

Ensuring Precision in Glass Cutting with Laser Machines

Precision in glass cutting with laser machines can be assured through several methods. The first step is accurate calibration of the machine, ensuring that the laser is correctly focused for the thickness and type of glass being used. Additionally, the use of high-quality software allows for precise control over the cutting trajectory, making it possible to achieve intricate and highly detailed designs. External environmental factors, such as temperature and humidity, should also be monitored and controlled, as they can affect the cutting process. Lastly, regular maintenance and inspection of the laser machine are vital for maintaining its cutting precision. By performing routine checks and replacing worn-out parts, the machine can consistently deliver high accuracy and precision in glass cutting.

Applications and Potential of Laser Glass Cutting

Laser glass-cutting technology has a wide array of applications across numerous industries. In the automotive sector, this technology is used to precisely cut windshields and windows, providing a flawless edge finish. Similarly, in the electronics industry, laser-cut glass is used in the manufacture of smartphone screens, tablets, and other touchscreen devices due to its high precision and quality finish. The solar industry also benefits from laser cutting technology, which is used to cut thin-film photovoltaic panels.

Moreover, the potential for laser glass cutting is vast and continually expanding. Advancements in fiber laser technology are paving the way for faster cutting speeds and even greater precision, opening up new possibilities for product design. Other potential future applications include the cutting of glass for augmented and virtual reality devices, flexible glass for foldable devices, as well as intricate patterns for decorative and architectural glass. With continuous technological development, laser glass cutting will undoubtedly play an increasingly prominent role in various sectors.

Applying Laser Technology for Engraving Glass Products

Laser technology also serves as an effective tool for engraving glass products, offering a high degree of detail, precision, and consistency. With lasers, delicate and intricate designs can be engraved on a variety of glass surfaces, from glassware and mirrors to architectural glass panels and automotive components. It operates by focusing a high-powered laser beam onto the glass surface, subtly altering its structure to create a permanent, fade-resistant design. This technology ensures a clean and damage-free engraving process, unlike traditional engraving methods that can risk chipping or breaking the glass. Furthermore, laser engraving machines can be programmed to repeat the same design flawlessly, making it an ideal solution for mass production. With the ability to produce both simple and complex designs, laser engraving technology is steadily transforming the glass industry, providing new avenues for customization and personalization.

The Role of Laser Cutting in Processing Stained Glass

In the realm of stained glass processing, laser cutting has revolutionized traditional methods, enabling unprecedented precision and complexity in design. Stained glass, known for its vibrant color and intricate patterns, benefits significantly from the precision of laser cutting. This technology allows for the creation of detailed and elaborate designs that would be challenging, if not impossible, to achieve with manual techniques. Laser cutting eliminates the risk of breakage during the cutting process, a frequent concern with this fragile material. Furthermore, it can make precise cuts along curved lines, creating smooth edges that require minimum subsequent processing. Laser cutting also facilitates the production of multiple identical pieces, a crucial factor in replicating designs for large-scale stained glass installations. As such, laser cutting technology is taking stained glass craftsmanship to new heights, preserving its historical charm while propelling it into the future with advanced design possibilities.

Exploring the Versatility of Laser Glass Cutting in Art and Design

Laser glass cutting technology’s versatility has expanded the boundaries of creativity in the field of art and design. Artists and designers can now utilize this technology to experiment with novel structures and patterns, which are otherwise difficult to achieve using traditional methods. In the realm of three-dimensional art, for instance, laser glass cutting allows for the creation of intricate geometric forms with perfect symmetry and precision. It also enables fine detailing, ensuring that every single line and curve contributes to the overall aesthetic of the artwork. Moreover, the technology’s flexibility extends to the customization of design pieces, enabling artists to cater to the unique tastes and preferences of individual clients. This has proven particularly beneficial in the realm of interior design, where customized glasswork can add a unique touch to the decor. From architectural installations to personalized home decor, the versatility of laser glass-cutting technology continues to transform the art and design industry, opening up new avenues of artistic exploration.

Industrial and Commercial Applications of Laser Glass Cutting

Beyond the realm of art and design, the industrial and commercial applications of laser glass-cutting technology are expansive and growing. In the electronics industry, for instance, precise and rapid glass cutting is essential for the production of components like smartphone screens and display panels. This technology is also fundamental in the automotive sector where it is used for cutting glass components of vehicles, including windshields and windows, with high precision and efficiency. Likewise, in the construction industry, laser glass cutting is utilized for creating customized architectural elements, such as glass railings or decorative wall panels. Additionally, the medical industry leverages this technology for the production of glass components for various medical devices. These diverse applications underscore the transformative potential of laser glass-cutting technology in various sectors, redefining manufacturing processes and product designs.

Innovations in Laser Glass Cutter Development and Automation

In recent years, significant advancements have been made in the development and automation of laser glass cutters. As the demand for precision and efficiency continues to rise across sectors, manufacturers are constantly innovating to improve the performance, speed, and accuracy of these machines. For instance, the adoption of AI and machine learning algorithms has enabled more precise cutting patterns and intricate designs that were previously unattainable. Automation has also increased the speed of operations, reduced labor costs, and minimized human errors. Furthermore, the development of ultra-short pulse lasers has revolutionized the field, allowing for cold processing of materials and, therefore, reducing the risk of thermal damage. These innovations not only enhance the capabilities of laser glass cutters but also broaden their applicability across various industries.

Advanced Techniques and Innovations in Laser Glass Cutting

Further advancing the field of laser glass cutting, techniques such as Filamentation and Stealth Dicing are gaining prominence. Filamentation, a non-ablative technique, uses ultra-short laser pulses to create a path of ionized gas within the glass, a filament, which can then be used to guide a separation crack. This method dramatically reduces micro-cracking and chipping, leading to cleaner and more precise cuts. Stealth Dicing, on the other hand, uses a laser to form modified regions within the glass, which can then be expanded further to generate a clean and uncontaminated cut.

Beyond these techniques, the integration of sophisticated software plays a pivotal role in enhancing the productivity and precision of laser glass cutting. For instance, software-controlled beam shaping allows the adjustment of the laser’s focal spot size and shape, offering greater control and adaptability. There are also developments in laser heads that can adjust in real-time to material variances, ensuring the consistent cutting quality.

Lastly, the trend of integrating Industry 4.0 principles into laser glass-cutting operations is creating a more interconnected, efficient, and automated manufacturing environment. Through the use of sensors, IoT devices, and advanced analytics, laser glass-cutting processes can be continuously monitored and optimized, leading to improved efficiency, reduced waste, and higher-quality quality products.

Utilizing Picosecond Laser Technology for Precise Glass Cutting

Utilizing Picosecond Laser Technology presents a revolutionary approach to precise glass cutting. Picosecond lasers, characterized by ultra-short pulses in the picosecond range (one trillionth of a second), offer unprecedented precision in material processing. The ultrafast laser pulses lead to a process known as cold ablation, where the material is rapidly vaporized without generating significant heat, an aspect that is particularly crucial in preventing thermal damage to sensitive glass materials. This allows for accurate, micro-scale cuts with minimal chipping and practically no heat-affected zone. Moreover, Picosecond lasers are compatible with various types of glasses, including those that are traditionally difficult to process. This makes them a versatile tool for a wide range of applications, from the manufacturing of consumer electronics to delicate medical devices. In conclusion, the introduction of Picosecond Laser Technology into the realm of laser glass cutting signifies a leap toward greater precision, flexibility, and overall quality in manufacturing processes.

Advancements in Laser Drilling and Surface Modification for Glass

In addition to precise glass-cutting capabilities, modern laser technology has also brought significant advancements to the field of glass drilling and surface modification. For instance, the use of femtosecond lasers has made it possible to drill high-quality micro-holes in glass, which is particularly advantageous for applications such as microfluidic devices or precision optics. The process is characterized by minimal chipping, low heat generation, and high dimensional accuracy, ensuring a superior end product.

Similarly, laser-induced surface modification has proven to be an effective technique in altering the physical and chemical properties of glass surfaces. Whether it’s creating hydrophobic or hydrophilic properties, introducing patterns, or improving adhesion for subsequent coating processes, lasers offer an unparalleled level of control and precision. These advancements have greatly expanded the range and capabilities of glass processing, opening up new possibilities for innovative applications and designs. As technology continues to progress, we can only expect this trend to strengthen, bringing even more sophistication to the world of glass manufacturing.

Exploring New Capabilities in Laser Cutting and Engraving Processes

As advancements in laser technology continue to surge forward, the capabilities in laser cutting and engraving processes have similarly evolved. The introduction of picosecond and femtosecond lasers has transformed the accuracy, quality, and speed of these processes. With their ultra-short pulse durations, these lasers minimize heat generation, resulting in precise cuts and engravings with minimal thermal damage to the surrounding material. This is particularly crucial in the field of micro-manufacturing, where the workpieces are typically delicate and have intricate details.

In terms of engraving, lasers can now create intricate patterns and details with astounding precision. Complex geometric patterns, nuanced gradations, and high-resolution images can now be engraved on a variety of materials, including glass, with unprecedented accuracy and clarity. This increased precision has broad applications, from creating detailed, personalized designs on consumer goods to producing microscopic features on industrial parts.

Moreover, the speed of these processes has improved significantly with the use of modern lasers. Faster engraving and cutting times not only translate into increased production rates but also greater efficiency in manufacturing processes.

In conclusion, the continually evolving capabilities in laser cutting and engraving processes are pushing the boundaries of what is possible in manufacturing, promising a future of increased precision, quality, and efficiency.

Adapting Laser Cutting Technology for Specialized Glass Processing

The adaptability of laser cutting technology to specialized glass processing reflects an important milestone in the manufacturing sector. This technology has been harnessed to deliver highly precise and accurate cuts on glass, a traditionally challenging material due to its brittleness and variable thermal properties. By utilizing ultra-fast lasers, it is now possible to conduct non-ablative cutting processes on glass, which involves creating a modified region within the interior of the material, thus allowing for cleaving along the desired path with minimal surface damage.

The laser-induced breakdown of the glass structure, coupled with an optimal cooling system, can mitigate the heat-affected zone, thereby preventing unwanted micro-fractures and maintaining the integrity of the glass. This capability is highly advantageous in industries such as electronics, where glass is increasingly used in the production of microchips, displays, and other high-precision components. Ultimately, the ability to adapt laser cutting technology for specialized glass processing opens new possibilities for innovative product development and streamlined production processes.

Integration of Automated Systems for Laser Glass Cutting Efficiency

The integration of automated systems within the laser glass-cutting process significantly enhances its overall efficiency. These systems incorporate sophisticated machine learning algorithms and robotic elements to optimize the cutting trajectory, speed, and power, ensuring precise and consistent output regardless of the complexity or volume of the task. Additionally, automated systems contribute to reducing manual handling and human error, further increasing the quality and reliability of the final product. Moreover, automation enables uninterrupted operations and faster production cycles, leading to substantial time and cost savings. As such, the synergy between laser cutting technology and automated systems not only revolutionizes glass processing but also boosts operational efficiency, ultimately enhancing the competitive advantage of businesses in the manufacturing sector.

Maximizing the Potential of Laser Glass Cutting in Various Industries

The potential of laser glass cutting transcends beyond the manufacturing sector, with its innovative application promising transformative effects in various industries. In the automotive industry, this technology ensures the production of high-precision glass components, ranging from windshields to in-car display units, enhancing both safety and aesthetic appeal. In the healthcare sector, it allows for the fabrication of intricate glass components used in medical devices, thereby contributing to advancements in patient treatment and care. In the renewable energy sector, laser glass cutting plays a crucial role in producing durable and efficient solar panels, thus driving sustainable energy solutions. With continuous technology development and broader industry adoption, laser glass cutting can catalyze significant advancements, pushing the boundaries of what is achievable across a multitude of sectors.

Enhancing Productivity and Quality through Laser Cutting Machines

The integration of laser-cutting machines into production processes greatly enhances both productivity and product quality. Their precision and high-speed operation eliminate the possibility of human error and minimize waste, leading to improved efficiency. Furthermore, the flexibility of laser cutting machines allows for a wide range of customization options without the need for tool changes, thereby accelerating production timeframes. From the quality perspective, the non-contact nature of laser cutting prevents material deformation, ensuring the production of high-standard, aesthetically pleasing products. The combination of these factors substantiates the role of laser-cutting machines as instrumental tools in optimizing business performance and maintaining a competitive edge in the marketplace.

Customization and Personalization Opportunities with Laser Engraving

Laser engraving presents vast opportunities for customization and personalization across various industries, enhancing the value proposition of products and services. Leveraging this technology, intricate and highly detailed designs can be permanently etched onto a myriad of materials, ranging from metal and glass to wood and leather. This flexibility in application opens up possibilities for bespoke product creation, allowing businesses to cater to the unique preferences of each customer. Additionally, laser engraving can be employed to add a personal touch to items, such as engraving names or messages, thereby elevating the emotional connection between the product and its owner. In industries like jewelry, homeware, and promotional goods, personalization through laser engraving can serve as a key differentiator, contributing to brand distinction and customer loyalty.

Addressing Specific Industry Needs through Laser Glass Cutting Applications

Laser glass-cutting technologies have enabled a significant leap in the glass manufacturing industry, addressing specific needs and challenges with unparalleled precision and efficiency. These systems offer a non-contact, stress-free solution to cutting intricate shapes and patterns in various types of glass, including tempered, laminated, and even bullet-resistant variants. For industries such as automotive, aerospace, and electronics, this means a streamlined production process with improved yield and reduced waste. In the realm of architecture and interior design, laser glass cutting unlocks new realms of creativity, allowing for the creation of complex, custom designs on windows, mirrors, and decorative glass pieces. Furthermore, the medical industry benefits from the precision this technology offers in creating minute, accurate cuts for laboratory glassware and surgical devices. Thus, laser glass-cutting applications are not only redefining production capabilities across different fields but also fostering innovation by enabling the realization of designs that were previously thought impossible.

Overcoming Challenges and Limitations in Industrial Glass Cutting with Laser

While traditional glass-cutting applications come with several challenges such as waste generation, manual handling errors, and limitations in design flexibility, laser cutting emerges as a robust solution. It is a non-contact process, which eliminates the risk of physical damage or contamination that may be caused by mechanical tools. With the precision and control the laser provides complex designs can be executed flawlessly, even on delicate glass types. This level of precision also reduces waste, as it minimizes the risk of breakage or discard due to errors. Additionally, the speed and automation of laser cutting systems lead to increased throughput, making it a cost-effective solution for long-term industrial usage. When it comes to challenges associated with thermal stress, laser systems mitigate this by deploying a tightly controlled beam, which delivers heat in a highly focused manner, reducing the risk of thermal breakage. Thus, laser technology overcomes traditional barriers in industrial glass cutting, paving the way for a more sustainable, efficient, and innovative future in glass manufacturing.

Future Trends and Advancements in Laser Glass Cutting Technology

As we move towards the future, laser glass-cutting technology is expected to witness significant advancements that hold the potential to further revolutionize the glass manufacturing industry. One prominent trend is the development of ultrafast lasers, which offer superior precision and minimum heat effect zones, broadening the possibilities for intricate and delicate glass designs. The rise of Industry 4.0 is also set to impact this sector, with Smart laser-cutting systems becoming increasingly prevalent. Such systems will leverage Artificial Intelligence and Machine Learning algorithms to optimize cutting parameters in real-time, ensuring impeccable quality and reducing waste. The integration of Internet of Things (IoT) technology will enable remote monitoring and maintenance of these laser systems, ensuring higher uptime and productivity. Furthermore, advancements in beam shaping technology promise to enhance the quality of cuts and extend the longevity of the laser tools. These trends and advancements are paving the way for a new era in the glass manufacturing industry, highlighting the growing relevance and potential of laser cutting technology.

Frequently Asked Questions

Q: How does laser glass cutting work?

A: Laser glass cutting works by focusing a concentrated beam of light, generated from a CO2 laser source, onto the surface of the glass. This intense heat energy melts or vaporizes the glass, creating a clean and precise cut.

Q: What are the advantages of using a laser for cutting glass?

A: The advantages of using a laser for cutting glass include high precision, minimal material waste, fast cutting speeds, and the ability to cut intricate shapes with smooth edges.

Q: Can thick glass be cut using a laser cutting machine?

A: Yes, laser-cutting machines equipped with CO2 lasers are capable of cutting thick glass with precision and efficiency.

Q: What kind of laser is best suited for cutting glass?

A: CO2 lasers are commonly used for glass cutting due to their high power and ability to be easily absorbed by glass material.

Q: Are there specific applications for laser glass cutting?

A: Laser glass cutting is used in various applications such as creating glass ornaments, architectural glass elements, smartphone screens, and automotive glass components.

Q: How is the laser cutting process different from traditional methods of cutting glass?

A: Laser cutting offers a non-contact cutting method, eliminating the need for physical tools that may cause surface damage to the glass. It also provides greater flexibility in cutting complex shapes and designs.

Q: What are the key components of a glass laser cutting machine?

A: A glass laser cutting machine typically consists of a CO2 laser source, a cutting and engraving head, an automatic cutting table, and software for controlling the laser parameters.

Q: Is laser glass cutting also suitable for drilling holes in glass material?

A: Yes, laser glass cutting technology can be used for the precise drilling of holes in glass, providing clean and accurate results.

Q: Can laser glass cutting be automated for mass production purposes?

A: Yes, automated glass-cutting machines equipped with lasers are commonly used for the mass production of glass components in industries such as electronics, automotive, and construction.

References

- “Laser Processing of Glass.” Journal of Laser Applications, 2019. Link. This academic journal article provides in-depth information on how lasers are used in glass processing, including cutting. It’s a valuable source for understanding the technical aspects of the technology.

- “Glass Cutting with Lasers.” Photonics, 2017. Link. This online article offers an overview of how laser glass cutting works and its various applications. It’s a beginner-friendly source that is easy to understand.

- “How Lasers Cut Glass.” Coherent, 2020. Link. This blog post on a manufacturer’s website explains the technology behind their laser glass cutters.

- “Ultrafast Lasers in Glass Cutting.” Optics & Photonics News, 2018. Link. This article explores the use of ultrafast lasers in glass cutting, highlighting future trends in the industry.

- “The Future of Laser Glass Cutting.” Glass Technology International, 2019. Link. This online article discusses the future of laser glass cutting, including the potential impact of AI and IoT.

- “Laser Glass Cutting Techniques.” Photonics Media, 2020. Link. This article provides detailed information about the different techniques used in laser glass cutting.

- “A Review on Laser Cutting of Materials.” Journal of Manufacturing Processes, 2016. Link. This academic journal article provides a comprehensive review of laser cutting technology, including its use in glass manufacturing.

- “Understanding Laser Glass Cutting.” Glass Magazine, 2020. Link. This online magazine article explains the basics of laser glass cutting, making it a handy resource for beginners.

- “Exploring the Applications of Laser Glass Cutting.” Engineering.com, 2018. Link. This article discusses the numerous applications of laser glass cutting, from automotive to electronics.

- “Laser Cutting Systems.” TRUMPF, 2020. Link. This manufacturer’s website provides information about their laser cutting systems and how they work, offering insight into the practical applications of the technology.

Recommended Reading: CNC Knife Cutting Machine