Are you looking to purchase a CNC machine and don’t know where to start? Purchasing the right CNC machine is an important decision, as it could greatly benefit your business or production workflow. In this blog post, we will provide all the information you need before buying a CNC machine and cover topics such as types of machines available, uses and applications of CNC technology, pricing considerations for both new and used machines, and more. Ultimately, if you want comprehensive guidance through the entire purchasing process so that you can make the wisest choice for your needs – this buyer’s guide is for you!

What Does CNC Mean?

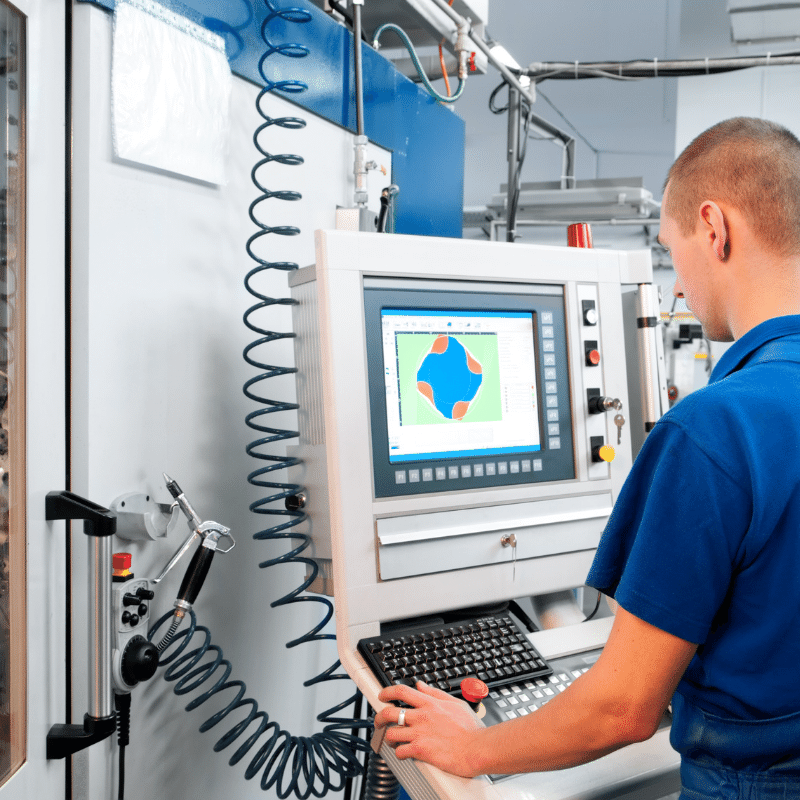

CNC stands for Computer Numerical Control and is a popular form of automation used in manufacturing. It is an effective way to increase production speed and accuracy by automating machine tools.

In CNC, a computer is used to control the movements of a machine tool such as a lathe, milling machine, router, etc. The computer can be programmed with instructions to move the tool in specific directions at particular speeds and depths. This eliminates the need for an operator to manually move the tool around.

CNC machines are commonly used in many industries including automotive, aerospace, medical device manufacturing and consumer product production. CNC machines are also widely used in metalworking shops for drilling, milling and turning operations. By using CNC machining techniques these processes can be done more quickly and accurately than by hand or other manual methods.

CNC technology has been around since the 1950s but has become much more advanced over time with advancements in computing power and software capabilities. Today’s CNC machines are capable of producing complex objects with high precision and accuracy with minimal waste and cost. There are many different types of CNC machines on the market today ranging from small desktop units up to industrial-sized models that can handle large amounts of material at one time.

Overall, CNC is a great way to streamline manufacturing processes while saving time and money. It allows producers to produce higher quality goods without sacrificing precision or accuracy. With its wide range of applications across multiple industries, it’s no wonder that this technology is becoming increasingly popular for businesses who want to stay competitive in today’s market.

Factors Affecting CNC Machine Cost of CNC Machines

CNC machines are becoming increasingly common in a variety of industries, from automotive to aerospace and beyond. As the use of these versatile tools increases, so does the cost of CNC machines. While there are many factors which influence the cost of CNC machines, understanding how each component affects the overall price can help business owners make more informed decisions when selecting a machine for their needs.

The first factor that impacts the cost of CNC machines is their size and complexity. Machines come in a variety of sizes and degrees of complexity, ranging from simple desktop versions to more advanced industrial-level units. Smaller machines tend to be cheaper than larger ones due to fewer components being required for operation and simpler designs. Complexity also plays a role in determining cost; as a machine’s capabilities increase, so does its price tag.

Material type is another important consideration when looking at CNC machine costs. Some materials require specialized cutting tools or processes which can add significantly to the final cost of the machine. In addition, some materials may require tougher tooling or additional steps such as cooling before they can be processed accurately with CNC technology. All these considerations need to be taken into account when selecting a material for machining with a particular machine model and budget in mind.

The speed of operation is also an essential factor affecting CNC machine cost. Faster-operating machines generally cost more than slower ones since they are able to achieve higher productivity levels with shorter cycle times, resulting in shorter delivery times and greater profitability for businesses using them. The amount of downtime associated with each project should also be taken into consideration when assessing the speed requirements for specific tasks; faster machines often result in lower maintenance and repair costs due to less wear on the parts over time, reducing overall operating expenses for businesses utilizing them.

Finally, another major factor influencing CNC machine costs is automation capabilities and features offered by various models on the market today. Automation options provide increased throughput levels while decreasing labor costs; thus they tend to be popular among customers willing to pay extra upfront in order to save long-term expenses related to manual labor or expensive product rework caused by operator mistakes during manual operations which can be avoided with automated technology on board . Automated tooling systems such as spindles or turrets are often present on higher-end models costing more than basic equipment without any additional features included; however these additions can result in considerable savings down the line for businesses taking full advantage of automated capabilities offered by modern CNC machinery today .

What is the Function of CNC?

CNC, short for Computer Numerical Control, is a type of automation used to fabricate a wide range of parts and components. It is a system that uses computers and numerical code to control machines such as lathes, mills, routers, grinders, and laser cutters. CNC machines are used in a variety of industries including automotive manufacturing, aerospace engineering, medical device production, and more.

For any given part or component design, the CNC machine will use numerical codes (G-codes) to determine the motion of the machine in order to manufacture the part. This is done by controlling the movement of the toolhead along multiple axes at different speeds and feed rates. The toolhead can be programmed to perform tasks such as cutting and drilling with high accuracy and repeatability.

The use of CNC machines offers many advantages over traditional machining methods. For instance, CNC machining can reduce material waste as well as labor costs since the machines are able to consistently produce parts with precise dimensions without having to be manually adjusted or monitored by skilled workers. Additionally, CNC machining can produce complex shapes that would otherwise be difficult or impossible to manufacture using traditional methods. Furthermore, with advanced software available today, CNC programs can often be modified quickly and easily allowing for quick turnaround times on manufactured parts or components.

For these reasons and more, CNC machining has become an essential process in modern manufacturing operations around the world. As technology continues to advance so too does our ability to create higher quality parts in larger quantities faster than ever before—all thanks to the power of Computer Numerical Control systems!

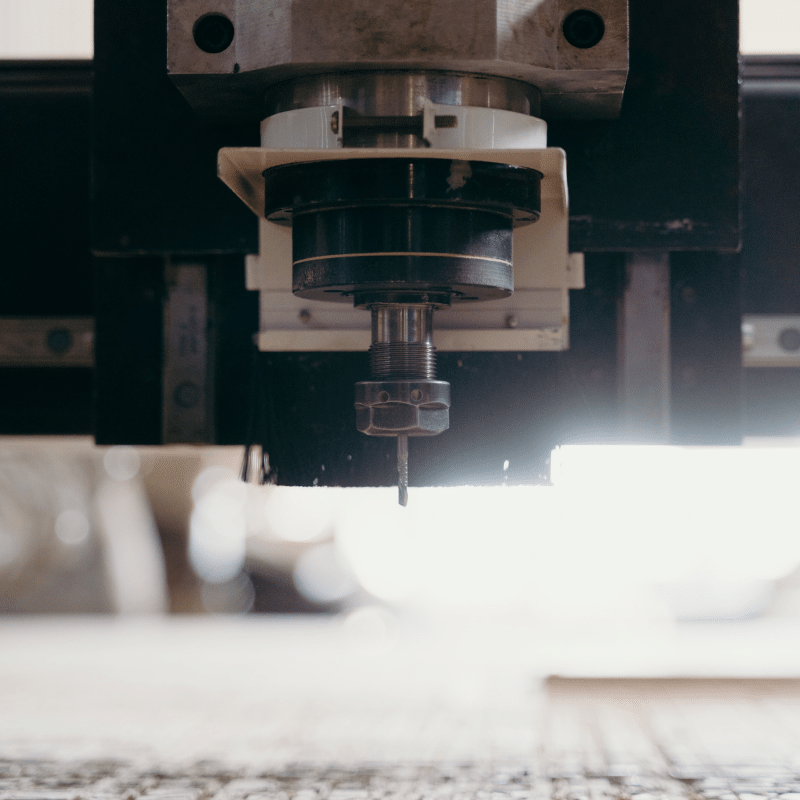

Hobby CNC Router Machine shop

Hobby CNC Router Machine Shops: Exploring the Pros and Cons of Using These For Your Next Project

Are you planning your next project but aren’t sure which type of machine shop to use? If so, you may want to consider a hobby CNC router machine shop. This type of machine shop is quickly becoming popular with do-it-yourselfers, makers, and more as they offer a wide range of advantages over other types of shops.

In this article, we’ll explore the pros and cons of using a hobby CNC router machine shop for your next project. We’ll also provide tips on what to look for when choosing one and how to make sure that your project turns out as expected.

What is a Hobby CNC Router Machine Shop?

Hobby CNC router machine shops are computer numerical control (CNC) machines that are designed specifically for home and small business use. They typically come preassembled with all the necessary components such as an industrial-grade spindle motor, stepper motors, drive systems, software programs, and safety features that ensure accuracy and precision in the work done by these machines.

Pros of Using a Hobby CNC Router Machine Shop

Cost Savings: Hobby CNC routers cost significantly less than professional grade models used in commercial applications. This makes them ideal for those who don’t have large budgets or for those who need only occasional projects completed.

Increased Accuracy: Since these machines are computer controlled, they produce highly precise results with greater accuracy than manual operations can achieve. This makes them ideal for intricate designs or high-quality pieces that require exact measurements.

Versatility: The tools used by these machines can be swapped out depending on the application which makes them incredibly versatile and capable of producing parts from almost any material including plastics, metals, wood, foam, etc.

Safety Features: Many hobby CNC routers come equipped with safety features such as emergency shut offs to protect both yourself and your equipment in case something goes wrong during operation.

Cons of Using a Hobby CNC Router Machine Shop

Limited Power/Size: Hobby routers typically lack the power to cut through thicker materials or larger parts due to their smaller size compared to industrial grade models; however this isn’t always an issue if you plan accordingly.

Limited Software Options: Unlike commercial grade models which offer extensive software options tailored toward specific applications; hobby versions often offer limited software choices making them unsuitable for certain projects like cutting complex shapes or intricate designs without additional programming expertise/knowledge.

Risk Of Injury: As with any type of machinery there is always some risk involved when operating it regardless of safety measures taken; therefore appropriate precaution should be taken at all times when using these machines even if you think you know exactly what you’re doing!

Finding the Right Hobby CNC Router Machine Shop For Your Needs

When looking for a hobby CNC router machine shop there are several factors to consider in order to ensure that it meets all your needs while still staying within budget constraints. These include researching different brands/models available so you can compare features such as power output/size capability versus price; looking into online reviews from previous customers; checking if extra training/support is included in case anything goes wrong during operation; reading up on tutorials provided by each manufacturer; and lastly contacting local product specialists who may be able to help guide your decision further if needed.

We hope this article has given you insight on why using a hobby CNC router machine shop could be beneficial for your next project as well as how best to go about finding one that suits your requirements perfectly! With careful consideration and research into what type of machine will work best for you coupled with proper safety measures put in place while operating it; we guarantee success no matter what your end goal may be!

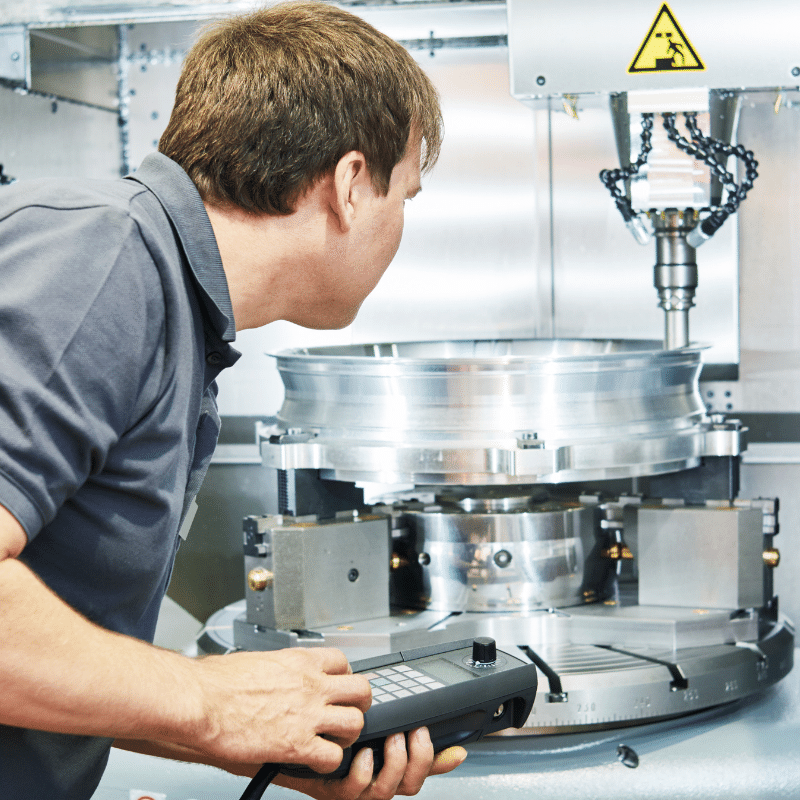

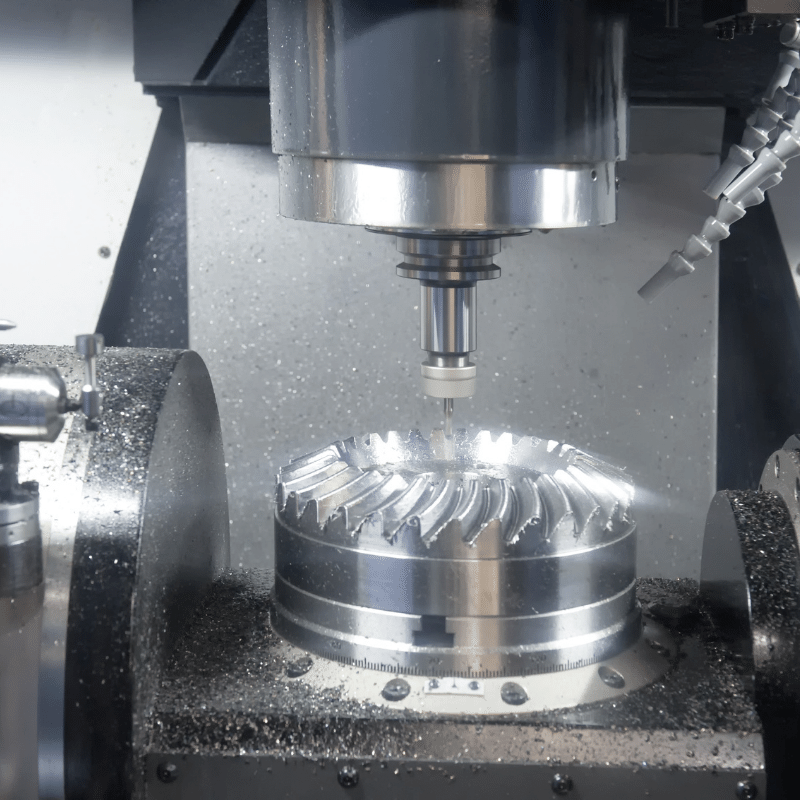

How Does a CNC Milling Machine Work?

CNC Milling machines are highly precise tools used for manufacturing complex parts and shapes. These tools can be found in industries such as aerospace, automotive, construction and medical device production. The CNC (Computer Numerical Control) milling machine is a type of sophisticated tool that uses computer control to move the cutting tools to create parts with high precision. The main components of a CNC milling machine are the CNC controller, the spindle, motors, axes, and the direction motion control system.

The CNC controller is a given program that directs how each part should be machined. This includes setting up the exact parameters for each operation such as spindle speed and feed rate. The program also indicates which particular cutting tool should be used for each operation. The spindle is the rotating cutting tool equipped in the machine; it is driven by either AC or DC motors. The motors drive the axes of the machine which includes X axis, Y axis, and Z axis to move along their designated directions creating 3D shapes with high accuracy. Lastly, direction control systems allow for further customization on movement of axes by enabling users to adjust speed, direction and number of rotations per minute (RPM).

The components discussed above are essential elements in order to operate a CNC Milling Machine efficiently. However before any manufacturing activity can take place there is one more step needed – CAD (Computer Aided Design). CAD software allows designers to consciously create 3D models of their product before they are machined into physical prototypes or parts. Furthermore these models contain all necessary information needed by CNC machines when programming operations that will eventually shape out these designs into real pieces..

In order for a CNC Milling Machine to work flawlessly, proper lubrication must always be applied on moving components such as bearings and rails where vibration tends to occur during operation. This helps reduce excess wear on equipment and maintains accurate movements at all times producing consistent results repeatedly without fail. Additionally regular maintenance such as cleaning off dust particles from inside parts ensures that no foreign object disrupts its performance during operations thus maintaining accuracy in creating desired products down to exact specifications set forth from its program instructions .

All in all a properly operated and maintained CNC Milling Machine will ensure successful production of quality parts with high precision at an efficient rate. From aerospace engineering companies fabricating air frames to medical device manufacturers crafting intricate implants; these machines have become invaluable assets in many industries today due to their extreme versatility and reliability when executing complicated tasks constantly over time without sacrificing quality workmanship!

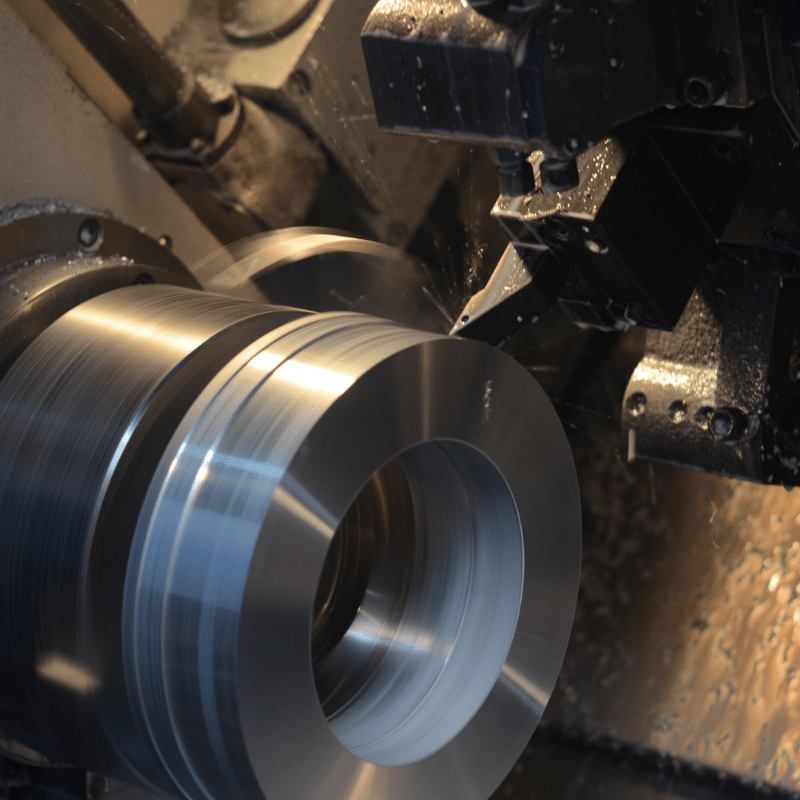

Entry-Level 2-axis Lathe Machines

Lathe machines are a vital tool for any shop or workshop that needs to create precise, round shapes from metal, wood, or other materials. One type of lathe is the entry-level 2-axis lathe machine, which is designed to be easy to use and affordable for hobbyists and professionals alike. With the right knowledge and maintenance skills, these machines can offer years of reliable performance for a variety of applications.

There are many benefits to using an entry-level 2-axis lathe machine. For starters, these machines are usually very user friendly and require minimal setup time before they’re ready to use. Additionally, they require less space than larger models, so they’re ideal if your workspace is limited in size. Most 2-axis lathes also have excellent control capabilities over speed, feed rate, depth of cut, and more. This makes them well-suited for precision operations like threading and drilling.

For those new to metalworking or woodworking projects but don’t want to invest too much money into equipment, entry-level 2-axis lathes can be a great investment. They typically come with basic features such as manual threading and adjustable cutting tools that will allow you to achieve professional results with minimal effort. This makes them ideal for novice machinists who want to learn the basics before investing in more complex systems down the road.

When choosing an entry-level 2-axis lathe machine for your needs, you should consider a few key factors first. First, make sure you think about the type of material you plan on working with most frequently—this will help determine what type of chuck accessories you’ll need later on down the line. Additionally, pay attention to features such as spindle speed range and power feed rates, as these will affect how quickly you can complete tasks with your machine. Finally, make sure that whatever model you choose includes good documentation in case you ever encounter any problems during operation or maintenance.

Overall, an entry-level 2-axis lathe machine is an excellent choice for anyone looking for a versatile tool capable of performing precision operations at an affordable price. With the right knowledge and dedication to upkeep practices like regular cleaning and lubrication checks, these machines can provide years of reliable service that even experienced machinists would be proud of!

What are the prices of a CNC Milling Machine?

CNC (Computer Numerical Control) milling machines are computer-controlled machines used to create intricate and precise shapes, parts, and components. They are used in industrial production processes and can be found in many manufacturing settings, such as machine shops, automotive shops, and even woodworking shops. These machines can be quite expensive; however, the cost of a CNC mill is determined by several factors including type of material being milled, size of the machine, features included, and operator experience.

The most basic CNC mills usually begin around $6000 USD depending on the brand and quality of machine you purchase. Hobbyist models may cost several hundred dollars less but won’t include all the features or capabilities of more expensive models. As you move up in the price range for CNC mills, you will find larger sizes with more features that increase the accuracy and speed of machining projects. Professional-grade machines with automated capabilities can easily run tens of thousands of dollars. For example, ATC (Automatic Tool Change) mills allow for efficient tool changes,, improving accuracy and reducing time spent on projects.

When looking for a CNC milling machine it’s important to consider what your needs are in terms of size, power, speed, accuracy and cost. It would be best if you also considered how much space you have available for installation and any maintenance or training requirements that may be necessary to ensure optimal performance from your new machine. Additionally, when purchasing a CNC mill, it’s important to look at what software is included with the package or if additional software must be purchased separately. If additional software is required then this could dramatically increase the overall cost of your setup over time so it’s important to do research on all options before making your final decision.

Overall CNC milling machines are an excellent investment for industrial production processes however they come with a significant financial commitment so it’s important to do research before making any decisions about which model would best meet your needs. With careful consideration given to size requirements, budget constraints, and other factors like maintenance costs and training requirements,, you can find an affordable yet reliable solution for your shop or business that will help take productivity to the next level.

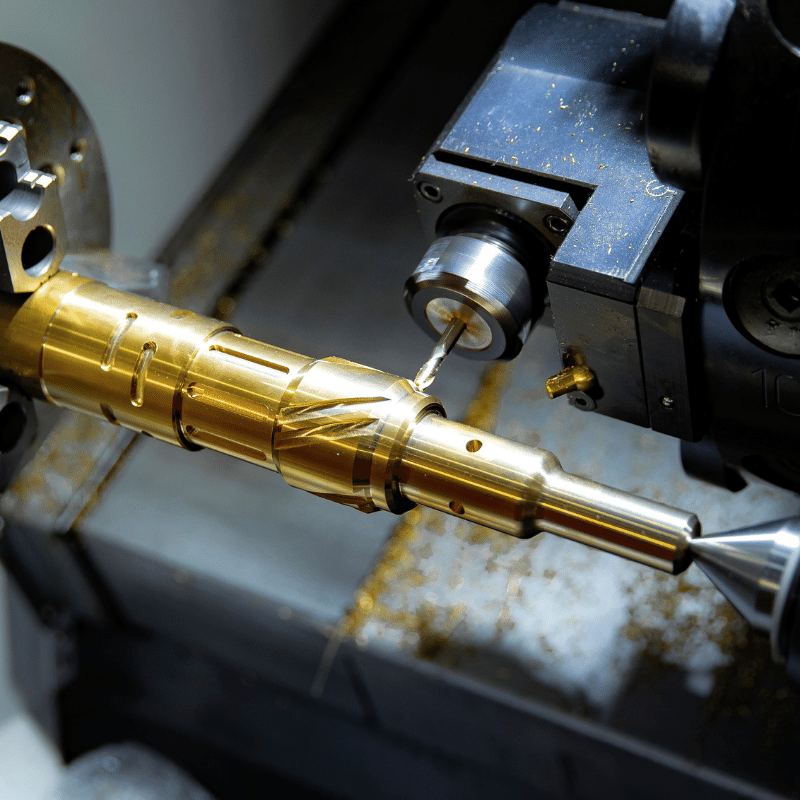

Small CNC Lathe Machines

Small CNC Lathe Machines are an invaluable production tool in many industries. They offer increased efficiency, accuracy, and speed over traditional manual lathes, making them the perfect choice for high-volume production runs. CNC lathes are designed to produce precision parts with minimal manual intervention and can be used for metal and plastic components.

CNC stands for Computer Numerical Control. This type of machine is operated via a computer control panel, which allows the user to program the machine’s movements accurately and repeatably with G-Code instructions. This eliminates human error from the process and ensures that each part produced is exactly identical to its predecessor.

CNC lathes generally consist of a spinning headstock, tailstock, and bed ways. The headstock houses the spindle, motor, tool holders, and encoder system which controls the movement of the cutting tools along one or more axes. The tailstock provides support for longer pieces and additional tooling when needed. The bed ways provide ways for the cutting tools to move in all directions across the workpiece while maintaining accuracy between cuts.

The main components of a CNC lathe include motors, servos/drives (to convert electrical signals into mechanical motion), controllers (for programming), coolant systems (to regulate temperature during long operations), tooling systems (to hold cutting tools) as well as other safety features such as guard doors/shields to protect operators from flying debris during machining operations.

CNC lathes offer several advantages over traditional manual machines, including faster setup times due to their automated processes; improved accuracy through precise control of speeds and feeds; increased material flexibility due to their adjustable cutting speeds; greater safety due to built-in safety systems; higher productivity due to their ability to run multiple operations simultaneously; reduced costs associated with material requirements since they can make more parts using less material; as well as overall improved quality of output compared to what can be achieved with manual machines.

Due to their cost effectiveness, reliability and ease-of-use, small CNC lathe machines have become essential equipment in many modern factories around the world. Whether you need parts quickly produced in large quantities or highly complex one-off pieces manufactured with precision accuracy – small CNC lathe machines are up for the task!

The price of a CNC machine also depends on the size of the investment you wish to make

A CNC machine is an invaluable tool for any business, helping to increase production speed and accuracy. However, the cost of investing in this technology varies widely depending on the size of the investment and the specific features required, so it’s important to know your needs before making a purchase.

The price of a CNC machine depends on a variety of factors, such as the type and model of machine, level of automation, levels of performance desired, and number of axes. Higher-end models with more advanced features often come at a higher price. Different manufacturers also offer different pricing structures with different advantages and disadvantages. Understanding each smanufacturer’s offering can help you select the best option.

The larger the investment, the more complex and powerful your CNC machine can be. This means that it is possible to purchase smaller machines at lower prices while still achieving excellent results; however, investing in larger and more powerful machines provides greater flexibility when machining materials or quickly creating larger numbers of parts.

When budgeting for a CNC machine purchase it is important to factor in both maintenance costs over time as well as other options such as third-party support services which may reduce downtime due to unexpected issues occurring with your machinery. Investing in good quality spares and regularly servicing your equipment will also help keep running costs down over time.

It is also important to consider any additional safety measures as part of your purchase, such as enclosures or light curtains which can help prevent accidents in busy workspaces. Finally, don’t forget about training; purchasing appropriate training materials or signing up for a course can help you make sure everyone working on the CNC machine knows how to do so safely and efficiently while avoiding potential damage or injury caused by misuse or poor technique. Taking all these factors into consideration will ensure that when you buy a CNC machine you are getting maximum value for money whilst meeting all your production needs.

Other Costs Associated with CNC Machines

CNC machines are necessary for industrial and commercial operations, but the cost of acquiring one is not just about the initial purchase price. Buying a CNC machine requires understanding the additional costs associated with owning and operating one. Knowing these additional expenses can help potential buyers make informed decisions when selecting the right CNC machine for their needs.

The first cost to consider after purchasing a CNC machine is installation. Depending on the type and size of the machine, installation can range from a few hundred dollars up to several thousand dollars, plus any additional fees associated with configuration or customization. Power requirements must also be taken into consideration, which means there may need to be new electrical wiring installed or existing wiring upgraded in order to safely run the machine.

In addition to installation costs, other ongoing operational costs must be considered when budgeting for a CNC machine. These include maintenance and repair costs and operating supplies such as cutting fluids and coolants, drill bits, and tooling fixtures. A company should also factor in any training needed for personnel operating the CNC machine. This can include on-site trainings from a technician and off-site classes offered by educational institutions or trade associations.

Another important expense is software licensing fees if specialized software is needed to control the CNC operations (e.g., CAM software). Additional accessories such as bar code readers or vision systems may also be necessary depending on what type of parts are being machined on the CNC equipment – these items come with their own associated cost.

Finally, energy consumption is another major factor that should not be overlooked when buying a CNC machine; monitoring power usage can help keep running costs down while ensuring maximum operation efficiency at all times. To do this effectively requires specialized instrumentation such as wattmeters or ammeters so that you can measure current draw from individual components and optimize performance accordingly.

Overall, potential buyers must carefully weigh all additional costs before investing in a CNC machine to understand exactly how much it will cost them over its lifetime. Taking into account all of these factors upfront can save companies significant amounts of money down the road by avoiding expensive repairs due to poor maintenance practices or unexpected fees due to lack of adequate training for employees who use it on a regular basis. By doing your research ahead of time and understanding all related expenses associated with owning a CNC machine, you’ll be able to make an informed decision that best meets your needs while keeping your budget in check.

Maintenance requirement

When you’re in the market for a CNC machine, it’s important to consider not just its purchase cost but also its ongoing maintenance needs. In today’s blog post, we’ll discuss what kind of maintenance is required to keep your CNC machine running smoothly and at peak performance.

Most CNC machines require regular maintenance such as oil changes, filter replacements, and general cleaning. The exact frequency and type of maintenance will depend on the specific make and model of your CNC machine. It’s a good idea to consult the manufacturer’s manual for instructions on how often each task should be performed.

In addition to regularly scheduled maintenance tasks, any malfunctioning parts should be addressed immediately in order to prevent more serious damage from occurring. This may involve replacing broken or worn components or making adjustments to ensure the machine continues to perform correctly.

Aside from regular maintenance and repairs, you can take several other steps to ensure that your CNC machine remains in good working condition. These include regularly checking key components for signs of wear or damage, storing the machine in a clean environment free from dirt and dust buildup, and following proper safety procedures when operating the equipment.

By taking these proactive steps and performing regular preventative maintenance on your CNC machine, you can significantly extend its lifespan while ensuring that it continues to operate reliably and efficiently over time. Investing in a high-quality tool is an important decision, so don’t forget about taking care of it once you have it!

Additionally, you will need to consider the type of software and maintenance you’ll need

A CNC (Computer Numerical Control) machine is an invaluable asset for any manufacturing or fabrication business. But, before investing in a CNC machine, it’s important to factor in the cost of software and maintenance required to make the most of its capabilities.

The price of a CNC machine can vary widely, ranging from the low thousands to hundreds of thousands for large industrial machines. Additionally, various software and maintenance packages are available, depending on your particular needs. This can include CAD/CAM software to design and program the parts you want to create; post-processing software used to convert 3D models into machining instructions; and CAM simulation software used to simulate the production process.

When calculating the total cost of owning a CNC machine, you also need to consider the associated costs with operating it. These include things like labor costs for operators and technicians; tooling costs such as cutting tools and saw blades; power consumption; cooling systems; disposal fees for waste materials; as well as ongoing maintenance and repair expenses.

It’s also important not to overlook the cost of training staff on how to use the CNC machine safely and effectively. While some manufacturers may offer basic user training when purchasing their machines, more comprehensive programs may be required if you plan on using advanced features such as automation or robotics programming.

Finally, investing in a good quality preventative maintenance package can help extend the life of your CNC machine while preventing costly repairs down the line. Ask potential suppliers about their preventative maintenance packages before making your purchase decision.

In short, there’s much more than just buying a CNC machine that needs to be taken into account when planning your budget and calculating total costs – software, maintenance, personnel training, consumables and spare parts all add up – but taking these into consideration will ensure you have a successful operation with minimal downtime in years to come!

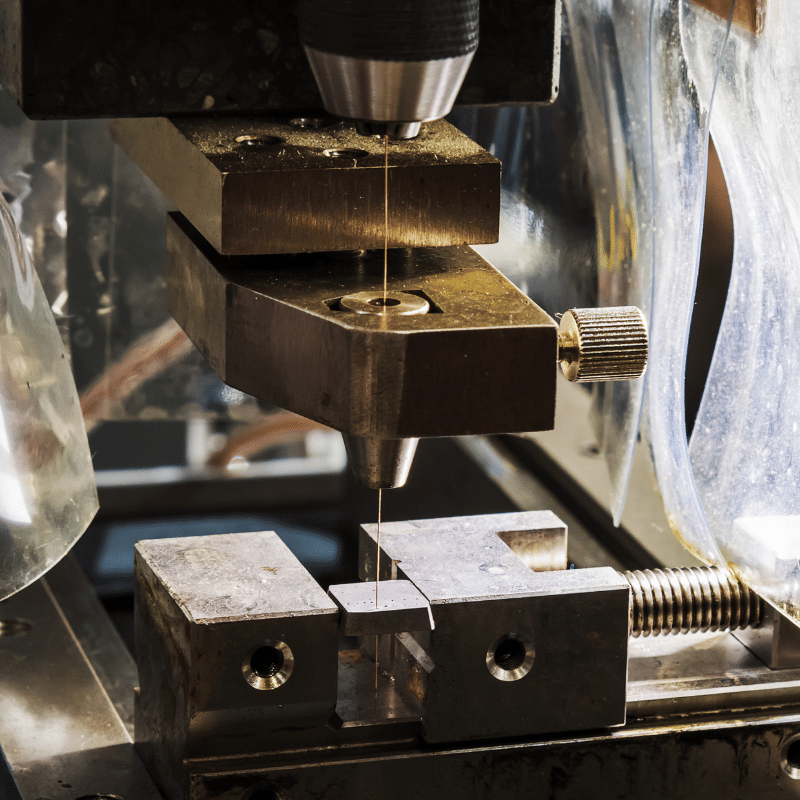

What are Some Common Uses of Wire EDM?

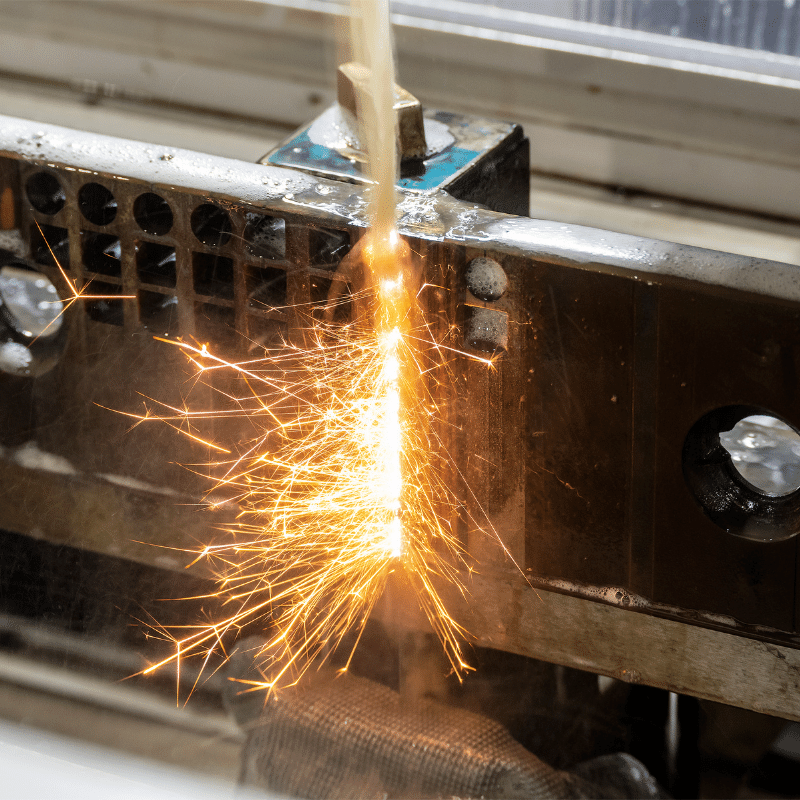

Wire EDM (Electrical Discharge Machining) is a unique process used in the manufacturing industry since the 1950s. It is a non-traditional machining process that uses electrical sparks to cut and shape metal workpieces. It can also be used to create intricate shapes and patterns in relatively hard materials like steel, stainless steel, aluminum, magnesium, titanium, and tungsten. The process involves feeding an electrically charged wire at high speed through the material being worked on. As the wire passes through the material, it cuts away small pieces of material, creating precise parts.

Most commonly Wire EDM is used for producing small precision components that require intricate details or shapes. This includes gears, dies, molds for injection molding, fuel injectors and other complex parts for various industries such as aerospace and medical fields. In addition to producing detailed parts with tight tolerances, it can also be used to produce functional surfaces like slots and grooves on metal components which can’t usually be produced using conventional cutting tools.

It is ideal for cutting materials that are difficult to machine with traditional methods due to their hardness or brittleness such as hardened steel or exotic alloys like Inconel or Hastelloy which are often used in aircraft engines and jet turbines. Because of its ability to work on harder materials at higher accuracy levels than traditional machining methods, Wire EDM has become increasingly popular in the production of automotive parts such as camshafts, crankshafts, piston rings, and connecting rods among others.

The Wire EDM process offers a number of advantages when compared to traditional machining methods including shorter lead times due to its faster cycle speeds; less tool wear since no mechanical force is applied during the cutting; improved surface finishes; better dimensional accuracy; and better repeatability because every part is identical within very tight tolerances regardless of how many units are made from one batch job. As a result this technology has seen widespread adoption not just in industries where precision components are required but also where large numbers of identical components need to be produced quickly such as automotive mass production lines where hundreds of thousands of parts may need to be manufactured from one set of drawings.

OverallWire EDM technology brings many benefits including improved efficiency and quality, increased productivity, cost savings over traditional machining processes and excellent repeatability for mass production runs making it an increasingly popular choice for many manufacturers looking for precision parts quickly without sacrificing quality or accuracy.

Software used in the CNC Machines

Computer Numerical Control (CNC) machines have become a cornerstone of the modern manufacturing industry. These machines, programmed with software to control machine functions such as cutting and drilling, have made it easier than ever to produce complex products quickly and accurately. But these modern marvels aren’t just hardware – they also rely on specialized software to operate correctly. In this guide, we’re going to take a look at the different types of software used in CNC machine operations, how they work together and how manufacturers can get the most out of their machines by using the right combination of software.

The first type of software used for CNC operations is known as Computer-Aided Design or CAD. This type of program is used for creating 3D models and drawings that can be used as reference points during the machining process. CAD programs also allow users to make changes and adjustments to their designs before they are sent to the CNC machine for production. Companies typically use professional-grade CAD programs like AutoCAD or Solidworks when designing parts for use with a CNC machine.

The second type of software used in CNC operations is Computer-Aided Manufacturing or CAM. This type of program takes the 3D models created with CAD and translates them into instructions that can be understood by a CNC machine. The CAM software also handles tasks such as toolpath generation and tool selection, ensuring that each part is machined correctly according to user specifications. Professional-grade CAM programs include Mastercam and GibbsCAM, both of which have been designed specifically for use with CNC machines.

The third type of software used in CNC operations is called Machine Tool Control or MTC software. This type of program enables users to control their machine tools from an external computer or other device through either a wired connection or via Wi-Fi technology. MTC programs let operators adjust feed rates, spindle speeds, coolant flow levels and more from outside the workshop area without having to manually adjust controls on site—a great convenience for busy production lines! Common MTC programs include Mach3 and Mach4 from ArtSoft Incorporated.

Finally, many companies choose to use data management systems alongside their CAD/CAM/MTC suite in order to keep track of all their materials usage across multiple machines within a single facility or even across multiple sites worldwide. Data management systems enable operators to monitor material levels, track stock movements between departments and warehouses, identify cost savings opportunities and more—all while providing valuable insights into production performance across multiple factors including cost per part produced, quality metrics achieved during machining cycles and cycle times achieved during processes like milling or turning operations. Common data management systems include Autodesk’s Fusion 360 Manufacturing Suite and Siemens’ PLM Software Suite Xcelerator package — both robust solutions designed specifically for use within industrial manufacturing environments like those found at most CNC shops today!

In conclusion, modern CNC operations depend on various types of specialized software working together in harmony so that operators can achieve complex tasks quickly and accurately while minimizing costs wherever possible along the way — something that would be impossible without a comprehensive suite consisting of CAD/CAM/MTC/data management systems working together seamlessly! With the right combination of these elements in place, manufacturers can ensure that their machines are up-to-date with industry best practices while reaching maximum productivity levels every time they go online!

The price of a CNC machine will also depend on the type of materials you plan to use, as these will determine the type of machine you need

If you’re looking to purchase a CNC machine, it’s important to understand how the price of the machine is impacted by the type of materials you plan to use. Different materials require different types of machines, and this will affect the cost of your CNC machine considerably.

When selecting a CNC machine for your material, there are a few key things to consider. First, the hardness and strength of your material will determine the type of cutting tool you’ll need to get the job done. Certain materials may require specialized tools that can be more expensive than general-purpose cutting tools. Additionally, each type of material has different machining requirements. Some materials may require high-speed spindles or high-torque motors, further increasing costs. Finally, some harder materials may necessitate coolant systems or dust extraction systems for safe operation and efficient machining times. All these factors come into play when determining the price of your CNC machine.

In addition to cost considerations, it’s also important to think about how certain types of materials may impact your production time and accuracy. Some softer materials might be easier to cut but lack precision while other materials might require higher levels of accuracy but longer machining times due to their hardness or brittleness. Selecting a suitable machine for your application will ensure optimal performance while ensuring efficiency in terms of machining time and cost per part produced.

Ultimately, choosing the right CNC machine for you depends on both budget and application needs; careful consideration should be given as to what type of material you plan on using with your CNC Machine so that you have a better understanding on what kind of machine works best for you financially and in terms of performance—allowing you to get maximum value from your investment over time.

Cost of Professional Woodworking CNC machines

If you are a professional woodworker, then you know the importance of having a high-quality, reliable CNC machine. Not only do these machines provide superior accuracy and precision when cutting and shaping wood, they also make it incredibly easy to create complex shapes with minimal effort. The cost of a professional-grade CNC machine can vary widely depending on its features and capabilities, but it’s generally safe to assume that it will be more expensive than a basic hobbyist machine.

When choosing the right CNC machine for your needs, there are several factors to consider. One of the most important is the size of the workspace. If you need a large workspace for larger projects then you should invest in a bigger model; whereas if you’re just doing small projects, then a smaller version may suffice. It’s also important to make sure that your chosen CNC has enough power to effectively cut through different types of wood: some machines specialize in hardwoods while others work better with softer varieties. The number of axes is another important factor: three-axis models are usually sufficient for most applications but five-axis machines offer greater flexibility and can allow for even more intricate designs.

The cost of professional-grade CNC machines can range anywhere from around $2,000 up to $50,000 or more depending on its features and capabilities. That being said, there are also some great options available at lower price points that still offer excellent performance and reliability; although they may lack certain features such as touchscreens or automated tool changing systems. Additionally, many woodworking professionals opt for used models which can be significantly cheaper than their brand new counterparts – just make sure to check them thoroughly before committing to any purchase!

In addition to the cost itself, it’s important to note that there may be additional expenses associated with owning and maintaining your CNC machine; such as special software packages or mechanical components that require regular servicing in order to keep your machine running smoothly over time. It’s also worth mentioning that purchasing a top-of-the-line model could actually save you money in the long run thanks to its improved accuracy and durability compared with cheaper alternatives – so always do your research before making any final decisions!

Finally, investing in a good quality CNC machine could be beneficial in terms of SEO ranking too since creating intricate shapes requires less effort than traditional methods – this means more time saved which could translate into better content creation overall. So while it might seem expensive at first glance; when you factor in all these different aspects and potential savings then investing in professional woodworking CNC machines might be worth considering after all!

Cost of Entry-Level Desktop CNC Routers (3018 CNCs and Chinese CNCs)

If you’re looking to enter the world of CNC routing, then you likely have a few questions. One of the most common is how much will it cost to get an entry-level desktop CNC router? There are two common types of lower-cost CNC routers: 3018 CNCs and Chinese CNCs. In this blog post, we’ll explore the pricing of these two options to help you decide which one is right for your needs and budget.

For many users, the 3018 type of entry-level desktop CNC router is the most popular choice. These machines are available from numerous suppliers, with prices ranging from just over $200 to around $1000 depending on features and build quality. At the lower end of the price range, you can usually expect a basic machine that does not come with a spindle or dust collection system. You may also find that some of these machines are limited in terms of cutting speed and accuracy compared to more expensive models.

Chinese CNC routers have become increasingly popular in recent years due to their relatively low cost and wide availability online. Prices for these machines typically range from around $200 – $500, making them more affordable than 3018 CNCs at times. The downside is that they tend to be less reliable than other brands since there can be significant variation between different models even within the same brand. Additionally, they may lack some features found on higher-end machines such as spindles and dust collection systems.

Ultimately, which type of entry-level desktop CNC router is right for you will depend on your budget and what kind of projects you plan on using it for. If you need more precision than a Chinese model can provide but still don’t want to spend too much money, then a 3018 type might be the way to go. On the other hand, if you’re looking for an inexpensive way to get started in the hobby or just don’t need high levels of accuracy, then a Chinese model could be worth considering despite its limitations.

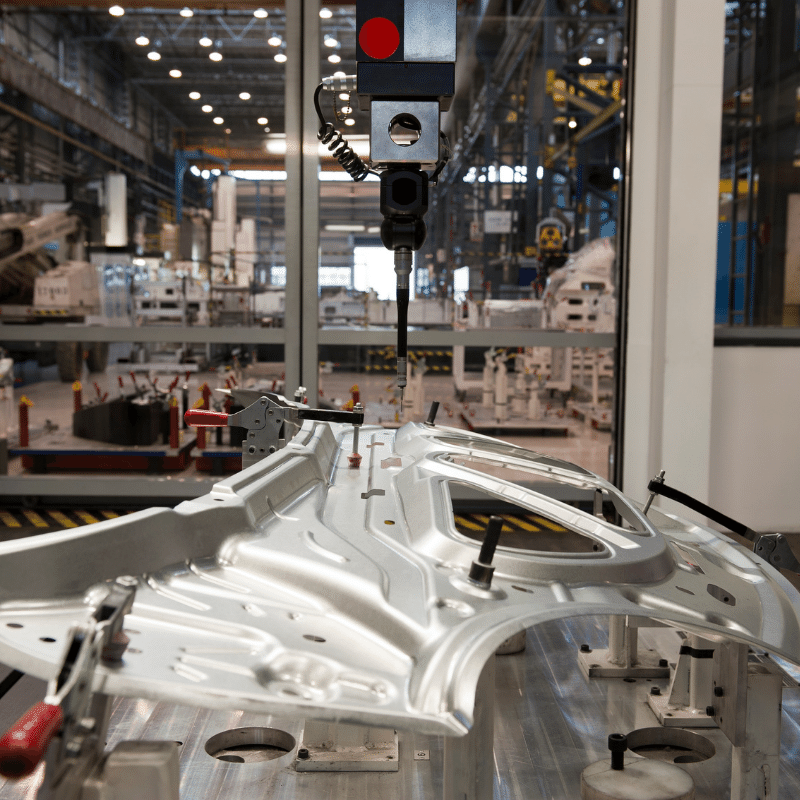

Cnc Machines Are Responsible For The Production Of Finished Products In Various Forms Such As Furniture, Art, Cars, And Electronics

CNC machines are responsible for taking raw materials and transforming them into the finished products we use in our everyday lives. From furniture to cars to art, these machines are revolutionizing the way we create. CNC stands for computer numerical control and is a technology that uses computers to automate certain manufacturing processes.

The process works by first programming a set of instructions into a computer that controls the machine’s movements. The instructions tell the machine what operations to perform such as cutting, drilling, milling, or turning raw material into objects with precision accuracy. Once programmed, the CNC machine can be used to produce multiple items quickly and efficiently with minimal waste. This makes it perfect for mass production tasks like car manufacturing and furniture making.

CNC machines have been around since the 1950s but are now becoming increasingly advanced thanks to new technologies such as laser cutting and 3D printing which allow even more intricate designs to be created with accuracy and speed. This has opened up a world of opportunity for creative makers who can use these machines to turn their ideas into reality.

Not only do CNC machines help make mass production efficient but they also help reduce human errors from manual processes which can lead to costly mistakes and delays in production times. Additionally, as many modern CNC machines are equipped with high-quality sensors and cameras, they can detect any discrepancies in their work and quickly alert operators so that corrections can be made before things progress too far along in the production process.

CNC machines have fundamentally changed how products get made today. They provide increased efficiency, accuracy, quality control, cost reduction benefits over traditional manual methods of production – all while leaving room open for creativity when designing products ranging from furniture to art pieces and electronics devices.

How Much Does a CNC Machine Cost?

CNC machines are a great way to automate complex manufacturing operations and increase precision in creating parts. But, like any piece of industrial equipment, these machines come with a price tag. Knowing what to expect when you’re in the market for a CNC machine is key to staying within budget while getting the best machine possible.

The cost of a CNC machine depends largely on the type and size that you need. Small desktop CNC machines designed for hobbyists typically cost between $800 and $3,500, with larger units costing upwards of $10,000 or more. Industrial-level machines can range anywhere from $20,000 to several hundred thousand dollars depending on their capabilities and applications. These prices don’t include accessories like CAM software or tooling packages either.

Another consideration when shopping for a CNC machine is the type of technology used in its manufacture. Machines built with older technologies may be cheaper initially, but they may require more maintenance and have shorter life-cycles than newer models. Machines made with aluminum frames rather than steel will also be cheaper upfront, but won’t have as much rigidity or stability when machining metals so it is important to consider your specific needs before making a purchase decision.

Finally, it is worth noting that some CNC machines come with additional features such as multiple tool holders or automatic tool changers that can add thousands of dollars onto the price tag. Other features like dust collection systems or integrated coolant systems may also increase the total cost significantly depending on your needs and budget constraints.

When considering buying a CNC machine, it is important to research different types of machines and shop around for competitive pricing to get the best value possible without sacrificing quality or versatility. A good understanding of your own needs combined with knowledge about what capabilities each machine offers will help you make an informed decision that helps you meet both your short term goals as well as long term objectives within your budget constraints.

The cost of a CNC cutting machine will depend on a variety of factors, including the type and size of material you need cut

If you’re in the market for a CNC (Computer Numerical Control) cutting machine, you’ll need to consider a few factors before making the purchase. The cost of a CNC cutting machine varies greatly and ultimately depends on the type and size of material you’ll be cutting. So it’s important to take into account your specific needs when budgeting for a new machine.

When considering the type of material to cut, it often comes down to two primary categories: non-metallic and metallic materials. Non-metallic materials are those like wood, plastic, aluminum, or acrylic which require fewer specialized tools. Metallic materials such as steel or iron require special cutting tools due to their hardness and durability. Depending on which category you fall into will depend on your budget for the machine itself as well as potential additional equipment costs.

The size of the material is also an important factor when purchasing a CNC cutting machine as larger sizes may require more advanced machinery than smaller ones. If you plan on cutting large pieces of material, then you may need extra power from your machine with more precise accuracy than what is necessary for smaller pieces. It’s also worth noting that some machines have adjustable bed sizes which can save time and money by allowing you to quickly adjust the size without needing to purchase another model altogether.

Beyond these factors, there are other considerations that may affect price including features such as speed, automation capabilities, cooling systems, ease of use, and warranty period among others. Knowing exactly what kind of work you will be doing with your CNC cutting machine can help narrow down your search so that you can make an informed decision about what type of machine will best fit your unique needs in terms of both cost and quality output.

Overall, understanding the cost associated with a CNC cutting machine is largely dependent on the type and size of material being cut as well as any additional features or options available with each model available on the market today. With this knowledge in hand, it should be easier to decide which model best suits your individual project requirements while still staying within budget – helping ensure good value for money spent!

What are Some Common Uses of Grinders?

Grinders are one of the most versatile tools in any professional or hobbyist’s arsenal. They can be used for a wide variety of jobs, from grinding metal to carving wood. The key to success is choosing the right tool for the job at hand. Here are some of the most common uses for grinders:

Metal Working: One of the primary uses for grinders is metalworking. This includes cutting and grinding down metal surfaces to shape them into usable parts or components. Grinders with diamond cutters and abrasive attachments can make quick work of tough metals like steel, aluminum, and brass. More specialized tools include die grinders that are used for removing small burrs from machined parts and angle grinders used to create beveled edges on sheets of metal.

Woodworking: Another popular use for grinders is woodworking. This can range from simple sanding jobs to more intricate projects like carving out patterns and designs in hardwoods such as maple, oak, and walnut. Woodworkers also use grinders with router bits to create grooves and slots in pieces of wood prior to assembly or finishing work. Many carpenters also rely on benchtop grinder wheels equipped with fiber discs or flap discs when tackling large-scale sanding jobs too big for manual sanding blocks.

Polishing: In addition to cutting, shaping, and grinding materials, grinders can also be used for polishing various surfaces such as concrete floors or countertops as well as metals such as brass or chrome fixtures. For instance, Tungsten Carbide burrs are often used by auto detailers when polishing up cars after a detailing session while high-speed buffing pads work wonders when restoring finishes on furniture pieces or other objects requiring a shiny finish.

Overall, there are many different uses for grinders depending on the type you have access to. From tungsten carbide burrs used for polishing cars to benchtop grinder wheels capable of sanding down vast amounts of material quickly and efficiently – there really isn’t much that these powerful tools can’t do! With so many possibilities available it’s no wonder why they’re considered an essential part of any toolbox regardless if you’re a professional craftsman or hobbyist looking to get started with DIY projects around the house!

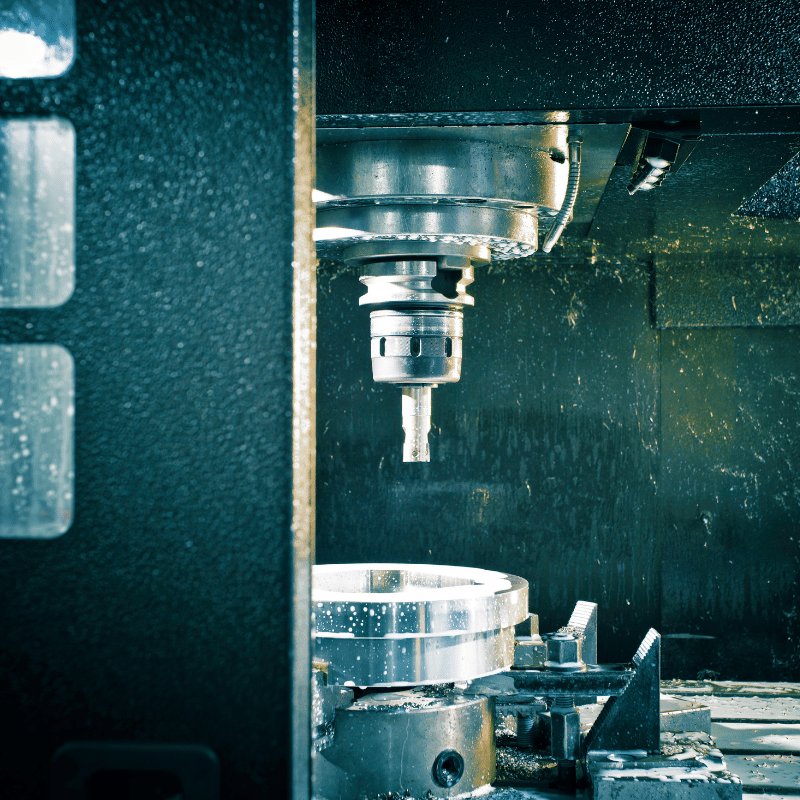

How Does a CNC Lathe Machine Work?

A CNC lathe machine is an integral part of the modern manufacturing process. It is a computer-controlled, automated device used to shape and finish components made of metal and other materials. Its ability to accurately cut, drill, and turn materials quickly has transformed the way companies manufacture their products. With its precise movements, it can produce complex parts with minimal effort.

To understand how a CNC Lathe Machine works, one must first understand the basics of Computer Numerical Control (CNC). This technology uses numerical code instructions to control machines such as cutters, milling machines and other lathes to create intricate parts from materials such as metals and plastics. A CNC lathe machine takes those numerical codes and translates them into motion that controls various components like spindles and tool holders.

The CNC lathe machine consists of three main components: a bed or frame, an axis system for controlling multiple turning tools; and a programmable control system. The bed is generally made up of steel or cast iron and holds the rotating workpiece in place while the cutting tool moves along it in either a linear or rotary motion. The axis system consists of two parallel axes that are connected by bearings to allow for precise movement of the cutting tool over the surface of the workpiece during machining operations. Finally, the programmable control system is responsible for running programs that define how each cutting tool will move along its respective axis in order to achieve desired results on the workpiece.

When programming a CNC lathe machine, engineers can specify feed rate (the speed at which material is cut) as well as operational characteristics like threading pitch, boring diameter, taper angles etc., all with just a few simple clicks on their keyboard or mouse. This makes programming jobs much simpler compared to manual setups where engineers would need to manually adjust multiple variables every time they wanted to make changes in parameters or processes. Once programmed with detailed instructions regarding which cuts should be made on what kind of material, the CNC lathe can be left alone until its tasks are complete – saving labor costs associated with manual labor inputs required for projects done conventionally by hand.

CNC Lathes have revolutionized manufacturing operations due to their accuracy and reliability when producing complex parts out of difficult materials such as stainless steel alloys or titanium composites using powerful tools like drills or broaches that would otherwise require extensive human labor if operated manually. Other advantages include high repeatability rates due to their precise movements resulting in fewer operator errors than standard manual operations; increased productivity because many more components can be produced in a shorter amount of time; significant cost savings associated with fewer man-hours required for precision machined parts; improved safety since complicated machining operations can be completed without any direct human contact; and higher accuracy/tighter tolerances than conventional methods due to advanced computer controls allowing higher speeds while maintaining precise results on even delicate components such as threads or grooves in metals.

Overall, there’s no doubt that modern CNC Lathes have changed how manufacturers approach product production through their ability to accurately produce complex parts quickly with minimal effort – thanks largely in part due to their highly accurate programming systems able to operate both linear and rotary motions simultaneously — enabling engineers around world build better products faster than ever before!

How Much Do CNC Laser Cutters Cost?

CNC laser cutters are becoming increasingly popular tools for a variety of industrial and commercial purposes. From prototype creation to small-scale production, these machines can provide precision cuts with minimal manpower. But how much do they cost? For those looking to purchase a CNC laser cutter, there is no one-size-fits-all answer—the price largely depends on the type of machine, its capabilities, and the vendor.

Basic CNC laser cutters are typically affordable solutions for hobbyists or small workshops. These machines usually have limited capabilities and power outputs, making them ideal for projects that don’t require intricate detail or high accuracy. Prices start at around $3,000 for an entry-level model. Higher end machines capable of more complex work may cost upwards of $20,000 or more.

For businesses requiring professional quality results and faster production times, larger format laser cutters—those with big enough beds to fit large pieces of material—are often the best option. These models can range from $30,000 to over $100,000 depending on their cutting area size and other features such as auto-focusing technology or air purification systems. When considering this type of machine it’s important to factor in additional costs such as gas delivery systems, exhaust systems and safety equipment; these can add thousands to the overall investment.

In addition to the cost of the actual machine, consider any associated overhead costs such as ongoing maintenance expenses or necessary upgrades like protective screens or dust collectors which are essential for safe operation of these machines. It’s also important to remember that good user training is necessary for safe operation—this can either be provided by the manufacturer or sourced from a third party provider at additional expense.

Ultimately when deciding whether a CNC laser cutter is right for you it’s important to look at both your immediate budget requirements and longer term goals before settling on a specific model. The right machine should meet your needs today while allowing you flexibility in future projects so you don’t outgrow it too quickly. With so many options available it pays off to do your research beforehand so you can make an informed decision that will not only save money in the long run but also deliver higher quality results right away!

How Does a CNC Laser Cutter Work?

A CNC laser cutter is a computer-controlled machine that uses a beam of light to cut or engrave materials such as metal, wood, acrylic, paper, and more. It works by focusing a high-powered laser beam onto the material that needs to be cut. As the laser beam passes through the material, it melts, burns, or vaporizes it away – leaving behind a precise and detailed design.

CNC stands for Computer Numerical Control. This means that the machine is controlled by a computer program which controls the motion of the cutting head. This allows for highly accurate cuts with minimal human intervention. The software used for controlling a CNC laser cutter can also be used to create intricate designs or patterns in the material being cut.

The power of the laser beam used in CNC laser cutting is measured in “watts” (W). Generally speaking, higher wattage lasers will produce faster cutting speeds and deeper cuts into thicker materials than lower wattage lasers. However, there are some limitations to this rule depending on what type of material needs to be cut. For instance, certain metals such as aluminum require lower wattage lasers because they are more reflective than other materials and can cause damage to higher wattage lasers if not properly treated with appropriate coatings or settings.

When using a CNC Laser Cutter it is important to ensure proper safety protocols are followed at all times due to its powerful light source and potentially dangerous fumes produced from melting materials. Protective eyewear should always be worn when operating this machinery in order to protect from potential eye injuries caused by exposure to intense light sources. Additionally, proper ventilation should be provided in order to disperse any hazardous fumes produced during operation.

CNC Laser Cutters have many uses ranging from industrial manufacturing applications such as car parts production to smaller scale personal projects like engraving photos or creating custom signs or decorations. With its precision cutting capabilities and easy setup process these machines have become increasingly popular among hobbyists looking for new ways to express themselves creatively without spending too much money on expensive equipment or tools needed for traditional woodworking projects.

Overall CNC Laser Cutters provide an efficient way of producing complex shapes quickly with extreme accuracy while also offering creative freedom with their wide range of projects they can accomplish – making them an excellent choice for both personal use and large-scale industrial production alike!

What are Some Common Uses of a CNC Lathe Machine?

When it comes to producing precision parts, the CNC lathe machine is a must-have for any manufacturing operation. A CNC lathe uses computer numerical control (CNC) technology to produce pre-programmed, highly accurate components with little or no operator intervention. This advanced machining tool can be used to turn, face, bore, thread and contour material in a variety of shapes and sizes. But what are some of the most common applications for this versatile piece of equipment?

One of the primary uses of a CNC lathe is for turning metal pieces into bolts, screws and other fasteners. The high accuracy and repeatability of this process make it ideal for meeting exacting standards and creating perfectly matched threads.

In addition to its ability to create custom fasteners, the CNC lathe can also be used for producing single-piece or multiple copies of complex parts with intricate geometries. Examples include nuts and washers, flanges, bushings, gears and spindles. Its power and versatility also enable users to craft components such as rods or hollow cylinders with inner passages – or even hollow spheres or cones – at high speeds.

Another key use of the CNC lathe is in making automotive engine blocks or crankshafts due to its unsurpassed repeatability combined with tight tolerances. It is also widely employed in the production of tools like taps and dies because they must meet extremely specific specifications that cannot be achieved by traditional methods alone. And with its remarkable capacity to hold close tolerances even after hours of running time with no manual adjustment required – CNC lathes are also frequently found on production lines for medical implants like pacemakers or prosthetics created from titanium alloys that require extreme precision.

In addition to its many industrial uses, hobbyists often use CNC lathes as well – especially those who make model trains or aircrafts where exact replication is essential along with accuracy in overall size dimensions.

Whether used by industry professionals or hobbyists alike, there’s no denying that a quality CNC lathe machine can help produce precise results quickly while saving time and money over traditional manufacturing processes

How Much Do CNC Plasma Cutters Cost?

CNC plasma cutters offer a cost-effective solution for quickly and precisely cutting metal parts with high accuracy. While the initial investment in a CNC plasma cutter can seem expensive, these machines offer a fast turnaround time for high-quality cuts and can even be used to create intricate designs. So when you’re weighing up the options of what tools to purchase for your business or project, it’s worth considering the cost of CNC plasma cutters.

When it comes to pricing, there is a range of options available depending on your budget, the size of your project, and the complexity of the designs you want to create. A basic desktop CNC plasma cutter machine typically costs around $3,000 – $5,000 USD while a full industrial machine may cost upwards of $10,000 USD. However this price tag doesn’t just include the machine itself – you need to factor in other associated costs such as plasma torches and consumables (materials which are expendable during cutting).

These costs can vary depending on factors like torch type; type and thickness of material being cut; gases used; speed settings during cutting; number of parts needing to be cut etc. Generally speaking though, consumables tend to account for about 5 – 10% of total operating cost over the life span of a machine (typically 5 – 7 years). This means that in most cases you can expect consumable costs to amount to less than half that of purchasing an entirely new machine every few years.

It’s important also factor in maintenance costs too – whether this is done by yourself or through hiring an experienced technician who can provide regular care and servicing as well as troubleshooting advice if needed. Maintenance fees vary from company to company but it is generally recommended that CNC plasma cutters are serviced every 6-12 months or after 500 hours of use (whichever comes first).

Overall then when looking at how much do CNC Plasma Cutters Cost? The answer really depends on factors like quality/model/power output; accessories such as torches and additional tips; materials needed for operation and overall maintenance requirements. It’s best to research thoroughly before committing but ultimately investing in one could prove more beneficial than having continuous replacements every few years due to cheaper running costs over time!

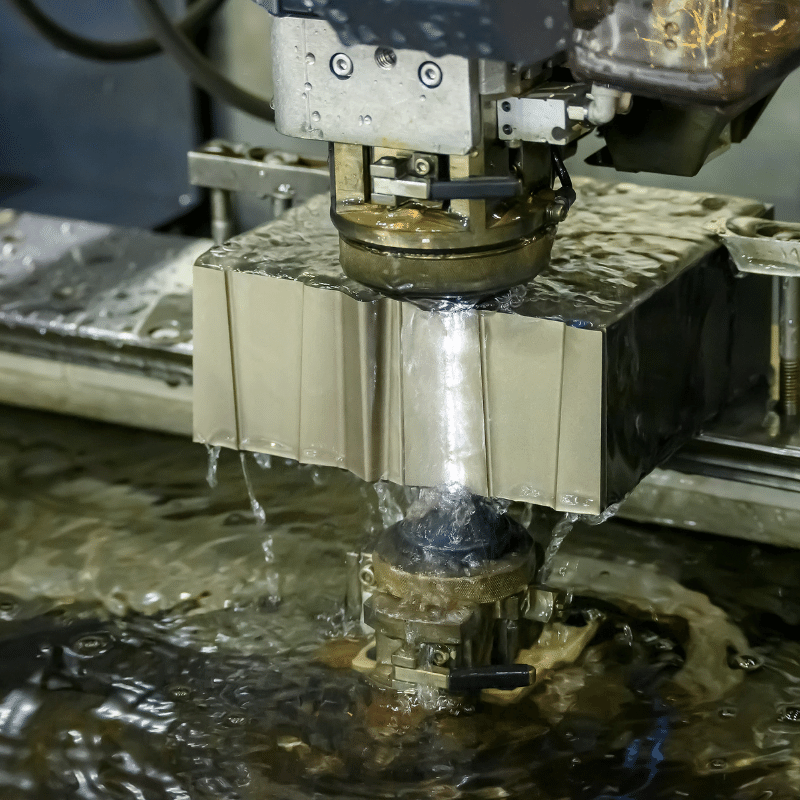

What Are Some Common Uses Of Waterjets?

Waterjets are powerful, versatile tools that can be used to cut and shape materials across a variety of industries. From aerospace to automotive, waterjet cutting is an efficient means of producing complex parts and intricate designs quickly and accurately. But what are the most common uses for waterjets?

In the manufacturing industry, one of the primary uses of a waterjet is for precision machining. Waterjets offer the capability to produce intricate shapes with tight tolerances that are difficult or impossible to achieve using standard machining techniques. For industries where quality and accuracy are essential, such as aerospace and medical device manufacturing, waterjet machining is often preferred over traditional methods.

Another common use for waterjets is in the fabrication of stone and glass products. This type of cutting provides a way to efficiently produce high-quality products with beautiful design elements—all without damaging delicate materials like stone or glass. Waterjet technology is also widely used in architectural projects such as creating customized tiles or mosaics to decorate lobbies, hallways, bathrooms, or other areas in a building.

Finally, waterjet cutting can be used for a variety of operations beyond just machining parts or fabricating products. It can be utilized for tasks such as deburring metal pieces, engraving wood carvings, etching custom logos into surfaces like steel plates or leather patches, creating custom gaskets from rubber sheets, and many more creative applications.

Overall, the versatility afforded by waterjet technology makes it an integral part of many industrial processes today—from making complex architectural creations to fine-tuning precision components for aircraft engines. With its ability to precisely cut any material without compromising accuracy or quality, it’s no wonder why so many companies rely on this powerful tool for their projects.

What are Some Common Uses of Routers?

Routers are an essential piece of technology that helps keep the internet running smoothly. They are used to route data between different networks, and can be found in virtually every home or business that has an internet connection. So what are some common uses of routers? Let’s take a look!

One of the most basic uses of routers is for routing data from a computer to the internet. Every time you connect to the web, your router sends packets of data out and receives them back from other networks. This ensures that all your online activities – from streaming movies to sharing photos – run smoothly and quickly.

Another use for routers is for creating secure connections between two points on two separate networks. Many businesses rely on VPNs (Virtual Private Networks) for secure communications, which require routers at either end. The router creates an encrypted “tunnel” between two points, allowing authorized users to access information without fear of its being intercepted by hackers or other malicious actors.

Routers can also be used as networking switches, which allow multiple devices within a network to communicate with each other. This is especially useful in home networks where there may be several computers, phones, tablets and gaming consoles connected wirelessly or through wired connections like Ethernet cables. Having a router allows the devices within the local network to share files, access printers and even stream content between them without going through a central server or using internet bandwidth.

Finally, many routers include additional features such as parental controls and antivirus protection, making them great tools for keeping kids safe online while still allowing them access to age-appropriate content. With these tools in place, parents can set limits on how much time their children spend online and even block certain websites if necessary.

In summary, routers are incredibly versatile pieces of technology that play an important role in keeping our modern lives connected and secure online. From connecting us to the web to providing a secure link between two points on different networks – not forgetting their use as networking switches – there’s no doubting their importance today!

How to Choose the Right CNC Machine Tools for Your Project

When embarking on a new project, it is important to select the right CNC machine tool that best fits your needs. There are many different CNC machines available on the market today and it can be difficult to choose one that will meet your project requirements. Here are some tips for selecting the right CNC machine tool for your project.

Consider Your Budget

The first step in choosing the right CNC machine tool is to consider your budget. Different types of machines come with varying prices, so you need to determine how much you are willing to spend upfront and also how much you can afford in overall maintenance costs over time. This should help narrow down your choices and help you find a good fit for what you need within your budget range.

Know Your Needs

Different projects require different capabilities, so it’s important to have a clear understanding of what features and abilities you will need from a machine before making any decisions. Consider if the machine has enough power and accuracy for the type of work that you require. Also remember that certain materials are better cut with certain types of tools, so make sure you select a tool that is designed to work with the material that you plan on using most often.

Research Different Types of Machines

Once you understand your needs and budget, it’s time to do some research on the various types of CNC machines available out there. Read customer reviews, watch videos online and compare prices from different manufacturers or retailers to get an idea of what each type offers in terms of quality and value for money. Knowing more about each type of machine will help narrow down your choices even further.

Ask For Advice

If all else fails, don’t hesitate to seek advice from industry professionals who have worked with various kinds of machines throughout their careers. They may be able to provide useful insights into which kind works best for specific tasks or applications, as well as other technical advice related to purchasing and setup process..

By taking these steps into consideration when selecting a CNC machine tool, you can ensure that you make an informed decision which will serve your business now – and into the future!

CNC Machine Size: How to Choose the Right Machine for Your Needs

CNC machines have become an essential piece of equipment for many manufacturing and industrial production operations. But with so many different sizes available, it can be confusing when selecting the right machine for your needs. Here we look at the key considerations when selecting a CNC machine size.

What Is the Purpose of Your CNC Machine?

The first thing to consider when choosing a CNC machine size is what purpose it will serve in your operation. Different types of CNC machines are designed to handle different kinds of work, including milling, drilling, turning, or routing wood, metal or composite materials. Understanding how the machine will be used will help you determine the right size and type of machine that best meets your needs.

What Is the Size of Your Workpiece?

Another important factor is the size of your typical workpiece. Many machines come equipped with standard bed sizes and X-Y axes ranges that must accommodate any workpieces that could be machined on them. If you are working with larger stock than a standard-size machine can handle, then you will need to purchase one with an extended bed length or capable of longer X-Y axis travel distances to process your pieces accurately and efficiently.

What Are Your Other Space Requirements?

In addition to choosing a CNC machine size that fits comfortably into existing workspaces and factory floors, considerations should also include whether other tools such as loaders, conveyors or dust collectors need to fit alongside it. A good range in sizes may enable you to integrate all these elements into one neat package while still providing enough room for operators and maintenance personnel around it safely and comfortably.

What Is Your Budget?

Given that top performance comes with premium prices it helps to define a budget before you shop around for a CNC machine size so you know exactly what options are available within your price range. Keep in mind that additional features such as spindle power ratings (horsepower), spindle speed limits (rpm) or acceleration rates may affect its cost significantly depending on the quality desired from each component part being machined on it. There are many things to consider when selecting just the right CNC machine size for your purposes but following this simple guide should ensure you find just what you need without overspending or sacrificing performance standards along the way!

What is a CNC Control System?

Computer numerical control (CNC) systems are automated machine tools that allow manufacturers to create precision parts and components. CNC control systems are an integral part of any modern manufacturing facility, allowing for precise computer-controlled production processes. In this blog post, we’ll explore what CNC control systems are, how they work, and the advantages they offer.

How Does a CNC Control System Work?

A CNC control system allows for automated machine operations by providing commands to the motors or servos in the system. The commands are usually generated from a 3D model or design file, so each component produced will be identical to its predecessor. This ensures accuracy and quality throughout the entire production process. The CNC controller communicates with the motors to precisely execute different movements such as cutting, drilling and milling through a series of inputs known as G-codes. These G-codes tell the machine tool which motion it should make including acceleration, deceleration and speed of movement. The codes also define where the tool should move relative to an object within its work envelope such as up/down or left/right.

Advantages of Using a CNC Control System

Using a CNC control system can significantly reduce time spent on manual labor while increasing accuracy and repeatability in production processes. Not only can these systems help save time when producing large volumes of products with intricate details, but they can also produce complex shapes quickly and accurately that would otherwise be too difficult or time consuming to achieve via traditional methods. Additionally, operators do not need extensive training to use them since most commands are pre-programmed into their software library. Another advantage is increased safety since many controls feature an emergency stop that immediately halts movement if triggered during operation. This eliminates any possibility of human error or injury stemming from negligence or fatigue during long shifts at a facility. Furthermore, these systems tend to require minimal maintenance because all redundant tasks like readjustment and calibration are automated by the software itself thereby saving time spent on upkeep regularly required with manual machines and equipment. Overall there’s no doubt that installing a cnc control system can significantly improve productivity and efficiency in any manufacturing setup – regardless of its size or scope – while helping increase safety at the same time!