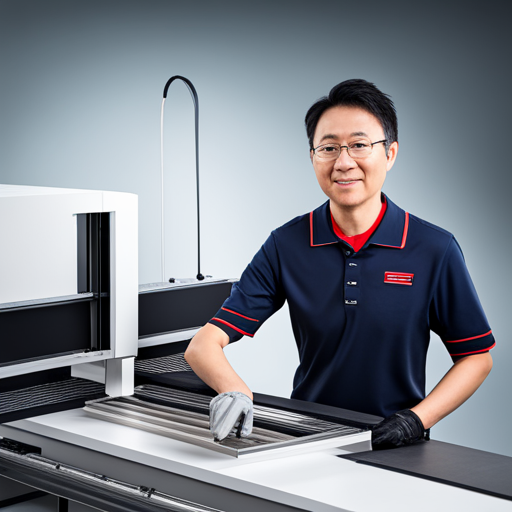

What is a metal laser cutter and how does it work?

A metal laser cutter is a precision tool that utilizes a high-powered laser beam to cut or engrave various types of metals. Two predominant types of laser cutters are CO2 lasers, which are typically used for cutting, boring, and engraving, and Nd: YAG lasers, often used where very high power is needed, for instance in boring and engraving. The process works by directing the laser beam through a nozzle to the workpiece. A combination of heat and pressure then creates the cutting action. The laser beam is typically 0.2 mm in diameter and has a power of 1,000 to 2,000 watts. This system allows for high-level precision and control, making it ideal for intricate designs and industrial applications.

Understanding the basics of laser cutting technology

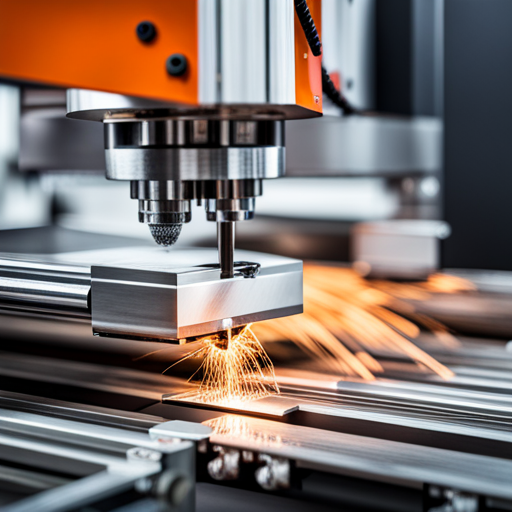

Laser-cutting technology hinges on the concept of directing a high-power laser beam onto a material that absorbs the beam, causing the material to heat up, melt, or vaporize. The power of the laser is concentrated on a tiny area, allowing for precise and accurate cuts. The laser either melts, burns, or vaporizes the material, blowing away the debris with a jet of gas, leaving an edge with a high-quality surface finish. The technology enables the user to cut complex shapes that would be otherwise difficult to achieve with conventional cutting tools. Two critical components of a laser cutter are the laser and the controller. The laser produces a beam of light that is reflected, intensified, and focused by the laser cutter’s lens and mirrors. The controller, on the other hand, manipulates the direction, intensity, speed of movement, and spread of the laser beam, which is directed onto the material’s surface for cutting or engraving.

Types of metal laser cutting machines available

There are several types of metal laser cutting machines available in the market, each designed to serve different purposes and accommodate varying material requirements. Below are some of the most commonly used machines:

- CO2 Lasers: These machines utilize a carbon dioxide gas mixture and are often used for cutting, boring, and engraving due to their high power output.

- Fiber Lasers: Known for their efficiency and precision, fiber lasers are perfect for detailed works. They are especially useful for cutting reflective metals, which can be challenging for other types of lasers.

- Nd: YAG Lasers: Short for Neodymium-doped Yttrium Aluminum Garnet lasers, these are used for high-power applications and can cut through thicker, denser materials.

- Nd Lasers: Also known as Neodymium Lasers, these machines are used for applications where high energy but low repetition is required.

Remember, the choice of machine largely depends on the specific requirements of the project at hand, including the type and thickness of the material, and the degree of precision required.

Comparing fiber laser cutters with other cutting technologies

When comparing fiber laser cutters with other cutting technologies, several factors come into play. Firstly, speed and precision are two areas where fiber laser cutters excel. They can cut with high accuracy and consistency, even when working with intricate designs and small pieces.

Secondly, energy efficiency is another advantage of fiber laser cutters. They consume less energy than other laser types like CO2 lasers, making them a more cost-effective and environmentally friendly choice for large-scale operations.

Thirdly, maintenance is less of a concern with fiber laser cutters. Due to their solid-state design, they don’t require regular replacements of gas reservoirs, unlike CO2 lasers.

However, it’s worth noting that fiber lasers tend to be more expensive initially, but their lower operating costs can offset this over time. As always, the choice between fiber laser cutters and other cutting technologies depends on the specific needs and budget of the manufacturer.

Factors to consider when selecting a metal laser cutter

When selecting a metal laser cutter, there are several key factors to consider:

- Type of Material: The kind of material you plan to cut is critical. Different laser cutters are suitable for different materials. Some are designed for metals, while others are better suited for non-metals.

- Power Requirement: The thickness of the material will determine the power required. Thicker materials will require a more powerful cutter.

- Precision Required: If the project demands high precision, opt for a machine that offers high accuracy and consistency.

- Production Volume: The scale of your operation is another consideration. If you are running a large-scale operation, you might need a cutter with a faster cutting speed and higher energy efficiency.

- Budget: The initial cost and ongoing operating costs are important factors. Some cutters may have a higher initial cost but lower operating costs.

- Maintenance: While some laser cutters require minimal maintenance, others may require regular upkeep. Consider the maintenance requirements and associated costs.

By taking these factors into account, you can identify a metal laser cutter that best fits your specific needs and budget.

Key features and specifications to look for in a metal laser cutter

When looking for a metal laser cutter, it’s important to consider the following key features and specifications:

- Cutting Speed: The cutter’s ability to maintain precision and accuracy at high speeds is vital for productivity.

- Wavelength: The wavelength of the laser affects its interaction with different materials. Make sure the wavelength is suitable for the metals you plan to cut.

- Laser Power: The laser’s power determines its ability to cut through different thicknesses of material. Opt for a higher power if you’re dealing with thick metals.

- Work Area Size: The size of the work area can limit the size of the materials you can cut. Consider your needs now and in the future.

- Cooling System: A reliable cooling system is essential for maintaining consistent performance and extending the lifespan of the machine.

- Software Compatibility: Ensure that the cutter is compatible with the design and modeling software your business uses.

- Safety Features: Check for safety features such as emergency stop buttons, protective housing for the laser, and safety interlocks.

- Service and Support: Look for a supplier that offers comprehensive after-sales service and technical support.

By paying attention to these features and specifications, you will be able to choose a laser cutter that is efficient, reliable, and safe for your metal-cutting needs.

Comparing CO2 laser cutters with fiber laser cutters for metal cutting

In comparing CO2 laser cutters to fiber laser cutters for metal cutting, several distinctions emerge. CO2 laser cutters are an established technology that offers excellent cutting performance for non-metal materials but they can struggle with reflective metals. They operate at a wavelength of 10.6 micrometers, making them less efficient when dealing with metals. The initial cost can be lower, but the operational costs are generally higher due to the requirement of consumables and higher power consumption.

On the other hand, fiber laser cutters use a solid-state laser, typically generated by rare-earth elements. They operate at a wavelength of 1.06 micrometers, which is significantly more efficient for metal cutting. They handle reflective metals well and provide excellent edge quality in thin materials. The initial upfront cost of a fiber laser cutter might be higher, but they tend to be more cost-effective in the long run due to their lower operational costs, faster cutting speeds, and greater energy efficiency. Fiber lasers generally require less maintenance and have a longer lifespan when compared to CO2 lasers.

In summary, while both laser types have their strengths, if metal cutting is a primary application, fiber laser cutters offer distinct advantages in terms of efficiency, operational cost, and maintenance needs.

Understanding the importance of cutting speed and precision

Cutting speed and precision are critical parameters in the laser cutting process, impacting both the quality of the finished product and overall productivity. Cutting speed refers to the rate at which the laser cutter completes a job. A faster cutting speed means greater throughput, improving operational efficiency and reducing production times. However, speed should not compromise the quality of cuts. Too high a speed may lead to poor edge quality and inaccurate cuts.

Precision, on the other hand, relates to the accuracy with which the laser cutter performs the cut. High precision is essential in industries where parts or components must adhere to stringent dimensional tolerances. Poor precision can lead to faulty parts, increased waste, and costly rework.

Balancing cutting speed and precision requires experience and understanding of the machine’s capabilities. While high-speed cutting may increase productivity, it should not come at the expense of precision. Conversely, extremely high precision may necessitate slower speeds. Thus, understanding and adjusting these variables to find the optimal balance is key to maximizing both productivity and product quality in laser cutting operations.

Assessing the maintenance and running costs of a metal laser cutter

Maintenance and running costs are significant factors to consider when investing in a metal laser cutter. The maintenance costs involve preventive measures such as regular cleaning, replacing worn-out parts, and ensuring the proper functioning of the cooling system. Maintenance can be periodic or as required based on the usage and wear and tear of the machine. Regular maintenance can extend the life of the machine and prevent costly downtime caused by unexpected breakdowns.

Running costs, on the other hand, include energy consumption, gas supply for the laser, and consumable parts such as lenses and nozzles. Energy consumption varies according to the power rating of the laser cutter – more powerful machines generally consume more energy but may offer faster cutting speeds, which can offset the higher energy cost by reducing job times. Gas supply costs depend on the type of laser used – fiber lasers, for instance, use a gas mix in the cutting process, which can add to the operational costs. Consumable parts, though relatively inexpensive individually, can add up over time and should be factored into the overall running costs.

Therefore, a comprehensive understanding of these costs is vital to calculate the Total Cost of Ownership (TCO), which is essential for making an informed purchase decision. This includes not only the upfront cost of the machine but also the ongoing expenses associated with its operation and maintenance. By doing so, businesses can ensure that their investment in a metal laser cutter is financially sound and aligns with their long-term operational goals.

Choosing the right laser power for your metal cutting requirements

When choosing the right laser power for your metal-cutting requirements, it’s essential to consider several key factors. The thickness of the material to be cut is one of the most significant considerations – stronger lasers are capable of cutting through thicker materials. However, they may consume more power and increase running costs. Cutting speed is another crucial factor. Higher-power lasers can cut faster, reducing job times, but this also comes with increased energy consumption. The type of material to be cut also influences the choice of laser power. Certain materials absorb certain laser wavelengths better than others, so understanding this relationship can help in selecting the most effective and efficient laser power. Lastly, always remember that higher power doesn’t necessarily mean better. It’s about finding the right balance between power, efficiency, and the specific needs of your operations.

Applications and benefits of using a metal laser cutter

Metal laser cutters are versatile machines that find application in diverse industries such as automotive, aerospace, industrial manufacturing, and even arts and crafts. They enable precise cuts and intricate designs that would be challenging, time-consuming, or even impossible with traditional cutting methods. One of the most significant benefits is the high degree of precision and repeatability they offer, leading to less waste and more efficient use of materials.

Additionally, laser cutting is a non-contact process, which minimizes wear and tear on machinery, reducing maintenance costs and prolonging machine lifespan. It also reduces the risk of material deformation that can occur with contact-based cutting methods. Moreover, the automated nature of laser cutting enables continuous operations, leading to significantly higher productivity. It’s also worth noting that advancements in control software have made metal laser cutters more user-friendly, allowing for greater design flexibility and faster setup times.

Exploring the versatility of metal laser cutters for different materials

Metal laser cutters exhibit remarkable versatility when it comes to handling different materials, thus widening their scope of applications. Let’s delve into a few examples.

- Steel: Steel is a commonly used material in various industries. Metal laser cutters can efficiently make intricate designs on steel, whether it’s stainless steel or mild steel, with high precision. The high power and accuracy of these machines ensure a smooth cut that requires minimal post-processing.

- Aluminum: Despite its lightweight nature, aluminum can be challenging to cut due to its high reflectivity and heat conduction. However, with specific laser parameters and the right assisting gases, metal laser cutters can deliver excellent cutting outcomes on aluminum.

- Copper and Brass: These materials are highly reflective and conductive, posing challenges for conventional cutting methods. Metal laser cutters, especially those equipped with fiber lasers, can effectively cut these materials while maintaining high precision and quality.

The ability of a metal laser cutter to handle a wide variety of materials amplifies its utility in diverse manufacturing processes, making it an indispensable tool in today’s industrial landscape.

Understanding the advantages of laser cutting in metal fabrication

Laser cutting offers significant advantages in the field of metal fabrication, contributing to its widespread adoption in various industries.

- Precision and Accuracy: Laser cutting involves a non-contact process, which results in minimal material deformation and therefore, high precision and accuracy in the final product. This is especially beneficial when dealing with intricate designs or small parts.

- Speed and Efficiency: Since laser cutting is automated and digitally controlled, it can operate at a faster pace than traditional cutting methods, significantly reducing production time.

- Flexibility: Laser cutting can handle a wide range of materials and thicknesses and isn’t limited by complex or intricate designs. The ability to switch quickly between different designs and materials makes it a versatile tool in metal fabrication.

- Reduced Waste: Laser cutting is highly precise, leaving minimal waste material. This not only results in cost savings for the company but also aligns with sustainable and eco-friendly manufacturing practices.

- Less Need for Finishing: Given the high-quality cuts produced by laser cutting, there is often less need for additional finishing or post-processing work, saving time and resources.

In summary, the advantages of laser cutting in metal fabrication are numerous, enhancing efficiency, reducing waste, and offering superior precision and quality in the finished product.

Explaining the potential for intricate designs and fine details with laser cutting

Laser cutting’s potential for producing intricate designs and fine details is unparalleled in the metal fabrication industry. The laser beam’s pinpoint accuracy, typically less than 0.1mm, enables the creation of complex shapes, patterns, and minute details that would be nearly impossible with traditional cutting methods. This precision is especially valuable in industries where intricate components are required, such as electronics, jewelry, and aerospace.

Moreover, the non-contact nature of laser cutting minimizes material deformation, preserving the integrity of even the most delicate designs. Its digital nature allows for easy adjustments and modifications, delivering design versatility. Changes can be made directly in the machine’s programming, eliminating the need for physical tool changes.

Finally, laser cutting also excels in repeatability. Even for highly complex designs, the laser can reproduce the same cut with high precision, ensuring consistency across multiple products or components. This capability is crucial for mass production scenarios where maintaining consistent quality is paramount.

Overall, laser cutting is a powerful tool that has revolutionized the manufacturing industry, enabling the creation of intricate designs and fine details with unprecedented precision.

Assessing the environmental impact and safety considerations of laser cutting

In assessing the environmental impact and safety considerations of laser cutting, it’s important to note that this technology is generally considered more sustainable and safer than traditional manufacturing methods. The precision and efficiency of laser cutting result in less material waste, contributing to its environmental friendliness. Moreover, the non-contact nature of the process means there is significantly less energy consumed compared to other cutting methods, further reducing its carbon footprint.

From a safety perspective, laser cutting systems are designed with numerous safety features and precautions to protect operators. These include protective housings to prevent direct contact with the laser beam, exhaust systems to manage fumes and particulates, and safety interlocks to halt operations if a hazard is detected. Nonetheless, proper training and adherence to safety protocols are paramount to ensure a safe working environment. Operators must wear appropriate protective gear, such as safety glasses, to shield them from potential laser reflections.

However, it’s worth noting that while laser cutting is overall more environmentally friendly and safe, it does present certain challenges. The process can produce harmful fumes and particulates that need to be effectively managed to prevent air pollution and health risks. This necessitates the use of robust ventilation systems and proper waste disposal methods. Furthermore, the high energy consumption of laser cutting machines, particularly high-powered ones, can also pose environmental concerns if not sourced from renewable energy. Despite these considerations, with proper management and adherence to safety protocols, laser cutting remains a viable and sustainable choice in manufacturing.

Comparing different types of laser cutting systems

There are principally three types of laser cutting systems: CO2 lasers, Nd: YAG lasers, and Fiber Lasers. CO2 lasers, the most common type, are versatile and used in a wide range of applications due to their high power and efficiency. They are ideal for cutting, boring, and engraving a variety of materials, including wood, plastics, and metals.

Nd: YAG lasers, on the other hand, are primarily used for boring and engraving, especially where high power is not necessary. They offer higher peak wavelengths, making them more suited to applications requiring fine detail work.

Lastly, Fiber lasers are recognized for their high energy efficiency and low maintenance needs. They have a shorter wavelength than CO2 lasers, resulting in a smaller spot size and a greater depth of focus, making them prime for precision cutting and engraving of metals.

Each system has its unique advantages and trade-offs, and the choice of laser depends on factors such as the material to be cut, required precision, power consumption, and budget. It’s crucial to examine these factors in detail before deciding on the most suitable laser-cutting system.

Understanding the differences between fiber lasers and CO2 lasers for metal cutting

When it comes to metal cutting, both fiber lasers and CO2 lasers present viable options, but each one brings distinct advantages and drawbacks. Fiber lasers, which operate at a wavelength of 1.064 micrometers, have a substantially smaller beam width than CO2 lasers, resulting in higher precision and improved cutting speeds. Additionally, fiber lasers require less maintenance due to their solid-state design and offer superior energy efficiency.

CO2 lasers, however, operating at 10.6 micrometers, boast an edge in cutting thicker materials where heat dissipation isn’t as critical. They are also capable of processing a wider range of materials, including certain plastics and wood, making them more versatile in various manufacturing environments. However, they can consume more power and require more maintenance compared to their fiber counterparts.

Ultimately, the decision between a fiber laser and a CO2 laser for metal cutting should be governed by the specific requirements of the task, including the type and thickness of the metal, desired cutting speed, energy efficiency considerations, and overall operational costs.

Exploring the capabilities of CNC laser cutting systems

CNC (Computer Numerical Control) laser cutting systems offer an unprecedented level of precision and automation in the manufacturing industry. These systems employ the use of computers to control machine tools, which can cut and shape a variety of materials with remarkable accuracy. These systems not only increase the speed and efficiency of production but also reduce human error and increase safety.

The capabilities of a CNC laser cutting system extend to intricate cutting and engraving designs on materials such as metals, wood, acrylic, and even leather. They can precisely cut complex shapes and patterns based on the programmed instructions, offering flexibility for customization.

Furthermore, these systems can operate continuously for long periods, making them ideal for large-scale production tasks. With the ongoing advancements in technology, CNC laser cutting systems are becoming increasingly efficient and cost-effective, providing significant competitive advantages for manufacturing businesses.

Assessing the suitability of sheet metal laser cutters for specific applications

When assessing the suitability of sheet metal laser cutters for specific applications, several factors come into play. One of the first considerations is the type and thickness of the metal. Stainless steel, aluminum, brass, and copper all have different properties that can affect the cutting process. A laser cutter’s power and the type of laser (CO2 vs fiber) will determine its ability to handle different thicknesses and types of metal.

The level of precision and intricacy required for the project is another key determining factor. Laser-cutting systems are favored for their ability to produce complex and precise cuts, making them ideal for detailed projects or patterns.

Operational costs can also sway the decision. While the initial investment for a laser cutting machine might be higher than other cutting methods, the total cost of ownership can be lower due to factors such as higher cutting speeds, automation, and lower maintenance costs.

Finally, the scale of production is a critical consideration. For large-scale production tasks, laser cutters’ ability to operate continuously for long periods makes them a viable option. However, for smaller operations, the investment in a laser cutter may not be justifiable.

In conclusion, the suitability of sheet metal laser cutters hinges on several factors – the type and thickness of the metal, the complexity of the design, operational costs, and the scale of production.

Maximizing the potential of a metal laser cutter

To maximize the potential of a metal laser cutter, users must understand and optimize several key parameters. Firstly, the power settings should be adjusted according to the material and thickness to ensure clean, precise cuts without any unnecessary damage or warping to the material. Secondly, the focus point of the laser plays a critical role in the quality of the cut. A laser cutter should be correctly focused, similar to a camera, to produce the sharpest, most efficient cut.

Maintaining the cutter is another crucial aspect of its optimum performance. Regular cleaning, alignment verification, lens and mirror checks, and replacement of worn-out parts are all part of a comprehensive maintenance regime. Lastly, using the right software can enhance the cutter’s capabilities, enabling automated and complex designs and improving productivity. By understanding and calibrating these variables, users can truly harness the full potential of a metal laser cutter.

Utilizing laser engraving capabilities for additional functionality

In addition to cutting, metal laser cutters can also be employed for engraving – a process of etching or marking surfaces with a design, lettering, or pattern. This feature extends the functionality of the machine and can add significant value to the final product. Laser engraving can be used to add serial numbers, logos, barcodes, or decorative details to a piece of metal. This is particularly useful in industries such as jewelry making, product identification, and precision engineering.

The process involves adjusting the laser’s power output, speed, and frequency to create varying depths of engraving and different levels of detail. The laser’s focal point can be altered to create wide or narrow engraving lines, depending on the desired effect. This process typically requires specialized software that can convert digital designs into instructions for the laser cutter. By effectively utilizing engraving capabilities, users can provide enhanced functionality and customization, making the laser cutter an even more versatile tool.

Understanding the integration of laser cutting systems within manufacturing processes

Laser cutting systems seamlessly integrate into the manufacturing process, contributing significantly to the automation and precision of production lines. They are compatible with computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, enabling precise cutting according to digitally created patterns. This integration is crucial in industries such as automotive, aerospace, and consumer electronics, where precision and speed are paramount. The automation facilitated by laser cutters minimizes human error and increases the rate of production, leading to higher efficiency and cost-effectiveness.

Moreover, the flexibility of laser cutting systems allows for easy alterations in the design process, making them ideal for both prototyping and mass production. The integration of these systems into manufacturing processes necessitates a thorough understanding of laser cutting principles and safe operating procedures. Proper training and maintenance are also essential to ensure the longevity and optimal performance of the laser cutting systems. Thus, with the right approach, laser cutting systems can be a game-changing addition to manufacturing processes.

Exploring advanced features for precision cutting in metal processing

Among the advanced features that make laser cutting systems crucial for precision metal processing, two prominent ones are high-speed piercing and contouring. High-speed piercing reduces the time taken to start a cut, enhancing overall product throughput. Meanwhile, contouring ensures that the laser follows the path of the design with high accuracy, yielding precise cuts.

Some laser cutting systems offer a ‘fly cutting’ option, an advanced feature that allows for continuous cutting of different shapes without lifting the laser head. This feature significantly increases cutting speed, especially when dealing with repetitive patterns.

Another notable feature is the ‘piercing detection’ tool, which minimizes damage to the material by detecting when the laser has successfully pierced through the metal. This feature is particularly useful when working with thicker materials.

Lastly, the integration of modern software allows real-time monitoring of the cutting process and provides predictive insights for potential errors or system malfunctions. This predictive maintenance feature can help to prevent costly downtime and ensure a smooth, efficient production process.

In conclusion, these advanced features enhance precision, speed, and efficiency in metal processing, making laser-cutting systems an invaluable asset in the manufacturing industry.

Assessing the potential for automation and enhancing productivity with laser cutting systems

The potential for automation with laser cutting systems holds immense promise for increasing productivity in the metal processing industry. Automated laser-cutting machines can operate without human intervention, enabling continuous production and significantly reducing manual labor costs. Furthermore, these machines exhibit high repeatability and consistency, ensuring that each cut mirrors the one before, thus eliminating the margin for human error.

Moreover, automated laser cutting systems are capable of multi-axis cutting, which allows for complex geometrical cuts. This feature expands the range of shapes that can be produced, enhancing the versatility of production processes. Additionally, these systems can be integrated with other automated systems, such as material handling or sorting systems, to further streamline production.

An important aspect to consider is the potential for enhancing productivity through predictive maintenance. By leveraging real-time data and advanced analytics, operators can identify potential issues before they result in system downtime, thus optimizing the overall production schedule.

In essence, the automation potential of laser cutting systems is a key driver of enhanced productivity, offering significant benefits such as reduced labor costs, improved product consistency, expanded production capabilities, and optimized maintenance schedules. As technology continues to evolve, we can expect even greater advancements in this field, further revolutionizing the metal processing industry.

Frequently Asked Questions

Q: How does a metal laser cutter work?

A: A metal laser cutter works by directing the output of a high-powered laser at the material to be cut. The focused laser beam heats, melts, or vaporizes the metal, creating a clean and precise cut.

Q: What are the advantages of using a fiber laser cutting machine for metal cutting?

A: Fiber laser cutting machines offer several advantages for metal cutting, including high precision, speed, versatility in cutting various metal types, low energy consumption, and minimal maintenance requirements.

Q: What types of metal can be cut with a laser metal cutting machine?

A: A laser metal cutting machine can cut various types of metal, including stainless steel, aluminum, copper, brass, and other alloys with different thicknesses and shapes.

Q: What factors should I consider when choosing a metal laser cutter?

A: When choosing a metal laser cutter, consider factors such as cutting speed, accuracy, cutting quality, operating costs, maintenance requirements, available features, and the specific metal materials you intend to work with.

Q: What are the key components of a metal laser cutting machine?

A: The key components of a metal laser cutting machine include the laser source, laser tube, cutting head, CNC controller, motion system, and auxiliary systems for laser cooling and gas delivery.

Q: Can a metal laser cutter be used for engraving?

A: Yes, metal laser cutters equipped with an engraving feature can precisely engrave text, images, and designs on metal surfaces, adding customization and personalization to metal products.

Q: What is the difference between a CO2 laser engraver and a fiber laser cutting machine?

A: A CO2 laser engraver uses a carbon dioxide laser source for engraving non-metal materials, while a fiber laser cutting machine utilizes a fiber laser source specifically designed for high-speed and precision metal cutting.

Q: How can a metal laser cutting machine improve productivity in metal processing?

A: A metal laser cutting machine can improve productivity in metal processing by offering high-speed cutting, precise and complex cutting capabilities, minimal material wastage, and the ability to automate cutting processes for efficiency.

Q: What are the maintenance requirements for a fiber laser metal cutting machine?

A: Maintenance for a fiber laser metal cutting machine typically includes regular cleaning of optical components, ensuring proper alignment, checking and replacing worn parts, and maintaining optimal operating conditions for the laser source and cutting system.

References

- [“CO2 vs. Fiber Laser Technology: Which is right for you?”](https://www.fabtech.org) – An insightful article from Fabtech, a leading authority in the metal fabrication industry, comparing the two major types of laser cutters and determining the optimal choice based on application and material type.

- [“A guide to buying your first laser cutter”](https://makezine.com) – A blog post from Makezine that provides a comprehensive buying guide for first-time laser cutter purchasers, covering key considerations and tips.

- [“Laser cutting process and its types”](https://www.sciencedirect.com) – A research paper available on ScienceDirect, discussing the different types of laser cutting processes and their respective advantages and disadvantages.

- [“TRUMPF Laser Cutting Technology”](https://www.trumpf.com) – A page on the manufacturer’s website where TRUMPF, a leading producer of laser cutting machines, details their technology and products.

- [“Principles of Laser Cutting”](https://www.springer.com) – A chapter from a book available on Springer, discussing the principles and dynamics of laser cutting technology.

- [“5 Factors to Consider Before Buying a Laser Cutter”](https://www.engineering.com) – An article from Engineering.com that outlines key factors to consider when purchasing a laser cutter.

- [“Laser Cutter Materials – What Can Be Cut, Etched and Marked?”](https://www.bosslaser.com) – A resource from BOSS Laser, a manufacturer of laser cutters, describing the different materials that can be worked with a laser cutter.

- [“Understanding the Operational Costs of a Laser Cutter”](https://www.machinemetrics.com) – A blog post from MachineMetrics detailing the operational costs of laser cutters and providing tips for cost reduction.

- [“Laser Cutting – An Overview”](https://www.sciencedirect.com) – An academic research paper from ScienceDirect, providing a detailed overview of laser cutting technology.

- [“Laser Cutting vs. Plasma Cutting: Understanding the Difference”](https://www.thefabricator.com) – An online article from The Fabricator that compares laser cutting with plasma cutting, two popular metal cutting processes.

Recommended Reading: CNC Knife Cutting Machine