What are the Different Types of Laser Cutters and Engravers?

Laser cutters and engravers are classified into three main types based on the type of laser used: CO2 lasers, Fiber lasers, and Crystal lasers.

- CO2 Lasers: These are the most common type used in small to medium-sized shops. The versatility of CO2 lasers makes them suitable for cutting, engraving, and marking a wide range of materials, including wood, plastics, fabrics, and coated metals.

- Fiber Lasers: Fiber lasers are excellent for marking and engraving metals or engineered plastics. They provide high-quality output, require minimal maintenance, and have a long lifespan, but they are typically not used for cutting operations.

- Crystal Lasers: These lasers are similar to fiber lasers in terms of the materials they can process and their applications. However, they are more expensive and have a shorter lifespan, which makes them less common in the industry.

Each type of laser cutter and engraver has its strengths and limitations, and the ideal choice depends on the specific requirements of the task at hand.

Understanding Diode Laser Technology

Diode Laser technology is a fourth type of laser technology that is increasingly gaining traction due to its efficiency and affordability. Diode lasers work by passing a high current through a semiconductor material. The energy from the current is transformed into light, creating the laser beam. These lasers are compact, offering a distinct advantage in situations where space is a constraint. Their efficiency is also notable – they convert input energy into light at a higher rate than other types of lasers, resulting in lower running costs. However, their beam quality is generally lower, which may affect the precision of the cuts and engravings. Despite this, Diode lasers are an excellent choice for hobbyists and small-scale applications.

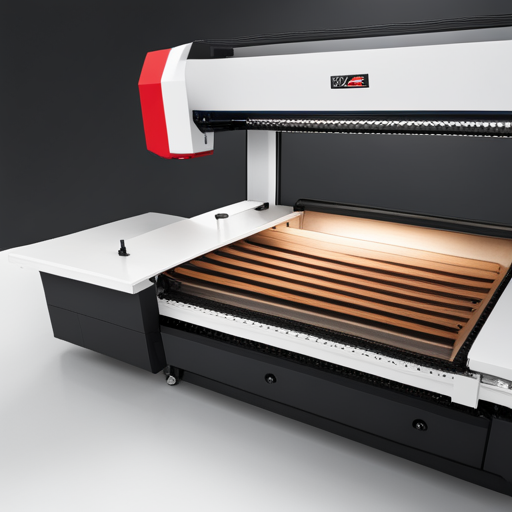

Exploring CO2 Laser Cutters

CO2 laser cutters are one of the most popular types in the industry, renowned for their versatility and high-quality output. Utilizing a gas mixture primarily composed of carbon dioxide, these lasers generate a beam through electrical stimulation. The capability of CO2 lasers to maintain continuous and high-power operation makes them suitable for applications involving cutting, welding, and marking a wide variety of materials.

The primary advantage of CO2 laser cutters lies in their ability to process a diverse range of materials, including glass, wood, paper, plastics, fabrics, and ceramics, along with metals when used with added oxygen. They are highly favored in industries such as manufacturing, fabrication, and arts and crafts, due to their precision and the quality of the finish they provide.

However, these machines also have their limitations. Continuous use at high power can lead to overheating, requiring an effective cooling system. CO2 laser cutters also typically require substantial maintenance, due to wear and tear on the mirrors and lenses used for beam delivery.

Despite these challenges, CO2 laser cutters remain an integral part of many industries and continue to evolve, with advancements in technology continually improving their efficiency and capabilities.

Comparing Desktop Laser Cutters

Desktop laser cutters are a compact and affordable solution, ideal for small-scale projects, hobbyists, or businesses with space constraints. These machines usually operate on lower power, generally in the range of 30 to 50 watts, making them suitable for engraving and cutting thin materials such as paper, fabric, wood, and some plastics.

Despite their smaller size, desktop laser cutters do not sacrifice quality, with many models offering high precision and resolution comparable to larger, industrial-grade models. They are designed for user-friendliness, often featuring intuitive software interfaces that simplify the design and cutting process. This feature makes them an excellent choice for educational contexts or beginner users.

The primary limitations of desktop laser cutters are their smaller cutting area and lower power. The compact size constrains the size of materials that can be processed, and the lower power limits the thickness of materials they can cut. Additionally, like their larger counterparts, desktop laser cutters require proper ventilation due to the fumes and smoke generated during operation.

In summary, desktop laser cutters offer a balance of affordability, compactness, and performance. They are a testament to how laser cutting technology has become more accessible, enabling creative exploration and prototyping right from a home or small office setup.

Choosing the Best Laser for Small Businesses

When choosing a laser cutter for a small business, several factors must be considered to ensure you get the most out of your investment.

Firstly, evaluate the nature of your business and the materials you will be primarily working with. If your business involves crafting intricate designs on thin materials, a desktop laser cutter with high precision may suffice. Conversely, if you anticipate cutting thicker materials, a higher-powered machine may be necessary.

Secondly, consider the space available in your business premises. Desktop laser cutters are compact and space-efficient, making them ideal for smaller workspaces. However, if space isn’t a constraint and you foresee a high volume of orders, investing in an industrial-grade machine might be a more effective long-term solution.

January 22, 2024

Thirdly, assess the technical savviness of the operator. Desktop machines often come with user-friendly software, making them suitable for beginners or those less familiar with CAD software. On the other hand, more complex machines may offer greater capabilities but require more technical knowledge.

Finally, don’t dismiss the importance of after-sales support. Check the warranty, availability of spare parts, and customer service quality provided by the manufacturer.

In conclusion, the best laser cutter for your small business will depend on your specific requirements, budget, and future growth plans. Conduct due diligence, weigh your options, and choose a machine that offers the best balance between cost and performance to maximize your return on investment.

Factors to Consider in Selecting a Laser Engraver

- Material Type: The type of material you will be engraving largely determines the kind of laser engraver you need. Some machines will not work for specific materials, so this should be your first consideration.

- Engraving Speed: The speed at which the machine can engrave a piece of work is crucial, especially if you’re running a business where time is money.

- Machine Durability: It’s important to look into the durability and lifespan of the laser engraver, as this directly affects your productivity and profitability.

- Software Compatibility: Ease of use and compatibility with your existing design software should be a major consideration. This will determine how easy it will be to transfer designs from your computer to the engraver.

- Safety Features: Look for a machine with features like automatic shutdown in case of overheating, and an eye-safe design to protect against laser reflection.

- Budget: Your budget will have a significant impact on the type of laser engraver you can afford. While more expensive machines generally have more features and capabilities, there are also cost-effective options that don’t compromise on essential features.

- Vendor Support: Finally, consider the level of support provided by the supplier. This includes technical support, availability of replacement parts, and warranty coverage. This can make a significant difference in the event of any technical difficulties or machine breakdowns.

How to Find the Best Budget Laser Engraver?

Finding the best budget laser engraver involves a careful evaluation of your specific needs and constraints. Here are some tips to guide you through this process:

- Define Your Needs: Understand what you need from the machine. Are you engraving small, delicate items or larger, robust materials? The size and type of material will determine what kind of budget laser engraver you need.

- Understand the Market: Research various brands and models available in your price range. Compare their features, capabilities, and customer reviews.

- Consider Second Hand: If your budget is very tight, consider buying a used machine. However, be cautious about the machine’s condition and its remaining lifespan.

- Check for Deals and Discounts: Keep an eye out for sales, discounts, or bulk deals from manufacturers or distributors.

- Prioritize Essential Features: Determine which features are crucial for your work and prioritize machines that offer these at the lowest cost. For instance, if you primarily work with a specific material, ensure the machine can efficiently handle that material.

- Do a Cost-Benefit Analysis: Considering the initial cost of the machine alone is not enough. Think about ongoing costs such as maintenance, repairs, and power consumption.

- Look for Good Vendor Support: A machine with strong vendor support can save you a lot of trouble and money in the long run. Check if the vendor offers adequate technical support, easy availability of replacement parts, and a good warranty.

Remember, the best budget laser engraver doesn’t necessarily mean the cheapest. Instead, it’s the one that offers the most value for your money while meeting your specific requirements.

Assessing Work Area and Engraving Capabilities

Another critical factor to consider when choosing a budget laser engraver is your work area and the engraving capabilities of the machine.

Work Area

The work area or engraving area refers to the maximum size of material that can be processed by the machine. Budget laser engravers come in various sizes, from small desktop models to larger industrial units. Be realistic about your requirements; if you’ll be working mainly on smaller items, there’s no need to pay extra for a large work area.

Engraving Capabilities

Assessing the engraving capabilities of a laser engraver goes beyond just checking the power specifications. You should also consider the system’s resolution, speed, and accuracy. High resolution is essential for detailed work, while speed and accuracy are crucial for maintaining productivity and achieving professional results. Be aware, though, that budget models may not offer the same performance as their more expensive counterparts.

In sum, when assessing work area and engraving capabilities, it’s important to align your expectations with your budget and the machine’s capabilities. Doing so will ensure you choose a laser engraver that best fits your needs.

Comparing Xtool D1 Pro with Other Budget Options

Xtool D1 Pro vs Other Budget Options

When we compare the Xtool D1 Pro with other budget laser engravers in the market, a few key differences become apparent.

Firstly, the Xtool D1 Pro offers a relatively generous work area for its price range, making it suitable for projects of various sizes. Its high resolution and accuracy also make it an excellent choice for detailed work. While it may not match the speed of premium models, the D1 Pro still maintains a competitive pace that can meet the demands of many users.

In terms of software compatibility, the Xtool D1 Pro stands out. It supports a wide range of design software, which provides users with the flexibility to work in an environment they are familiar with.

However, like all budget options, the Xtool D1 Pro has its limitations. Its engraving capabilities are not as advanced as more expensive models, and the machine may require more frequent maintenance.

In conclusion, while the Xtool D1 Pro has its pros and cons, its balance between price and performance makes it a compelling option for those seeking value within a constrained budget. It’s always important to assess these differences in the context of your individual needs to make the optimal choice.

Understanding Laser Power and Air Assist Features

The power of a laser engraver is measured in watts and directly impacts the machine’s ability to cut and engrave various materials. Higher power allows the laser to penetrate deeper and cut thicker materials. It’s crucial to understand what power level is suitable for your projects before selecting an engraver.

Air Assist is a feature found in many laser engravers that uses a stream of compressed air to minimize heat and flammable gases at the point of engraving. This function enhances the engraving quality by reducing heat-induced marks and preventing potential fires. It’s particularly beneficial when working with materials like wood or acrylic, which can easily burn or melt.

Understanding these features allows for an informed decision when choosing a laser engraver. Balancing the power needs for your projects with the benefits of features like Air Assist will lead to efficient and high-quality outcomes.

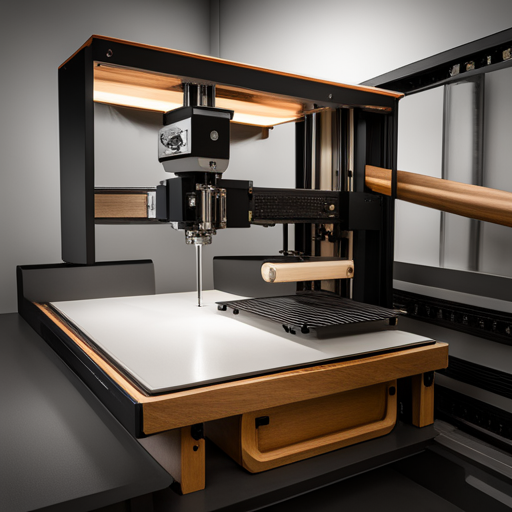

Exploring Budget CNC and Rotary Options

Budget CNC machines and rotary tools are an excellent choice for hobbyists and small businesses due to their affordability and relative ease of use. CNC machines, or Computer Numerical Control machines, automate the cutting process with their high-precision capabilities. These machines use CAD/CAM software to design and execute the cuts, offering a degree of precision that’s not possible with manual methods.

Lower-cost models, such as the Genmitsu 3018-PRO, provide a good starting point for beginners. It offers a compact size, supportive community for troubleshooting, and compatibility with popular design software like Fusion 360. While it lacks the power of more expensive models, it’s a capable and affordable entry point.

Rotary tools, on the other hand, are handheld devices that come with a variety of attachments for tasks such as engraving, cutting, or sanding. Affordable models like the Dremel 3000 offer a versatile toolset and are easy to handle, making them an ideal choice for detailed and intricate work.

Both budget CNC machines and rotary tools have their place in a crafting or workshop environment, and understanding each tool’s capabilities will help determine the best fit for your specific needs and budget constraints.

Considering 2023’s Top Picks for Budget Laser Engravers

As we look forward to 2023, several budget laser engravers stand out for their performance, cost efficiency, and user-friendly features. The Ortur Laser Master 2 is anticipated to continue its popularity, thanks to its large engraving area and rapid engraving speed. This model’s ability to work with a variety of materials including wood, leather, and plastic, makes it a versatile choice for various projects.

Next on the list is the NEJE Master 2S Max, a compact yet powerful laser engraver. With its easy-assemble design, this machine is great for beginners and experts alike, offering a hassle-free setup experience. Moreover, it’s compatibility with NEJE’s software and LightBurn gives users flexibility in design.

Finally, the ATOMSTACK A5 Pro deserves a mention. It comes equipped with a unique safety feature – a protective shield that blocks up to 99% of UV light. Plus, its adjustable laser focus allows for a high level of precision, making it an excellent choice for intricate designs.

In conclusion, these budget laser engravers offer a blend of cost-effectiveness and performance, making them a great choice for hobbyists and small businesses looking to expand their creative tools in 2023.

What to Look for in the Best Affordable Laser Cutter?

When shopping for the best affordable laser cutter, several key factors should be taken into consideration.

- Power Output: The power of the laser cutter is measured in watts, and higher wattage means the machine can cut through thicker and denser materials. Ensure the cutter has adequate power for your intended projects.

- Software Compatibility: Look for a laser cutter that is compatible with popular design software like AutoCAD, LightBurn, or Adobe Illustrator to streamline your workflow and design process.

- Cutting Area: The size of the cutting area will determine the maximum size of the material you can work with. Choose a dimension that suits your needs.

- Safety Features: Safety should never be compromised, so opt for machines with protective shields, safety sensors, and cooling systems.

- User Reviews: Read user reviews to get a sense of the machine’s reliability and performance. A machine with positive reviews and good customer support is often a wise choice.

Remember, the best affordable laser cutter for you will depend on your specific requirements, so take the time to assess your needs before making a purchase.

Exploring the Application of CO2 Laser Cutters

CO2 laser cutters are versatile tools used across various sectors due to their ability to cut, etch, or engrave on different materials. In the manufacturing industry, these cutters are employed for the precision cutting of metals and non-metals, resulting in cleaner and more accurate cuts compared to traditional cutting methods. They also find application in the fabrication of signage and promotional materials, where they can precisely carve intricate designs on acrylic, wood, or glass. In the fashion and textile industry, CO2 laser cutters offer unique solutions to create intricate patterns on fabrics, leather, or synthetic materials. Even in the medical field, these cutters play a crucial role in surgical procedures, providing non-contact, controlled tissue removal. In conclusion, the wide application of CO2 laser cutters showcases their flexibility and utility in diverse sectors, making them a valuable tool in both industrial and creative fields.

Understanding the Use of Cheap Laser Cutters for Small Businesses

Affordable laser cutters have become an increasingly popular tool for small businesses. These machines, despite their lower price tag, often provide a level of functionality and versatility that can meet the diverse needs of a small-scale operation. For example, in the craft and hobbyist sector, business owners utilize these machines to create bespoke designs on a variety of materials, enhancing the uniqueness and appeal of their products. In the prototyping stage of product development, laser cutters offer the ability to quickly and inexpensively produce prototype parts for functional testing. Even in businesses related to food and agriculture, laser cutters are used for tasks such as marking produce or creating customized packaging. Moreover, they can be a cost-saving investment, as they minimize waste through precision cutting, and require less maintenance due to fewer moving parts. In essence, the use of affordable laser cutters can contribute greatly to the efficiency, productivity, and creativity of small businesses.

Choosing the Best Materials for Laser Cutting and Engraving

When it comes to selecting materials for laser cutting and engraving, it’s important to consider characteristics such as the material’s ability to absorb the laser’s frequency, its heat resistance, and its hardness. For laser cutting, materials such as acrylic, wood, paper, and certain types of metal, like stainless steel and aluminum, are often used thanks to their excellent absorbency. On the other hand, glass and certain plastics are less suitable due to their reflective properties or sensitivity to heat. For laser engraving, materials that produce high contrast and detail, such as anodized or bare metals, leather, and dark woods, are preferable. However, materials like hard metals and glass, while able to be engraved, often require added processes for optimal results. Therefore, choosing the right material is crucial for successful laser cutting and engraving projects.

Assessing the Price Range and Features Available

When assessing the price range and features available for laser cutters, it’s important to note that there’s a significant variation. On the lower end, simple desktop models can start as low as a few hundred dollars, while industrial-grade laser cutters can reach into the tens of thousands. Key features to consider when selecting a laser cutter include power output, cutting speed, and the size of the cutting bed. Higher power output allows for faster cutting and the ability to work with denser materials. The cutting speed is a measure of how quickly the machine can complete a job, which is particularly crucial for businesses looking to scale production. The size of the cutting bed determines the largest material size the machine can handle. Other features to consider include ease of use, software compatibility, safety features, and after-sales service. Therefore, the choice of a laser cutter should be based on the specific requirements and budget of your business.

Comparing Diode Laser Cutters for Hobbyists and Professionals

Diode laser cutters offer distinct advantages for both hobbyists and professionals alike, but the requirements and preferences for each group tend to differ. For hobbyists, ease of use, affordability, and safety tend to be paramount. Diode laser cutters in the lower price range often come with user-friendly software, making them ideal for beginners.

On the other hand, professionals might prioritize power, cutting speed, and working area size, to cater to larger-scale projects and higher production demands. High-end diode laser cutters might also include advanced features like air assist, red dot pointer, or auto-focus, to enhance accuracy and ease of use.

Both groups should consider the durability and after-sales service of the product. While hobbyists might tolerate occasional breakdowns, professionals require consistent performance and quick customer service response times to maintain their production schedules.

In conclusion, the choice between different diode laser cutters should be guided by an understanding of your unique needs, budget constraints, and level of expertise.

Why You Should Consider a Budget Laser Engraver and Cutter?

Budget laser engravers and cutters are an excellent investment for several reasons. Firstly, they offer great value for money, providing a host of features at a comparatively lower cost. This makes them an attractive option for hobbyists and small businesses alike who are just starting their journey in laser cutting and engraving.

Secondly, budget options are often user-friendly and require less technical know-how, making them perfect for beginners. They usually come with intuitive software, allowing users to easily design and engrave intricate patterns.

Finally, despite their lower cost, many budget laser engravers and cutters still offer good quality and precision, enough to meet the needs of a variety of projects. Hence, they can serve as a stepping stone, allowing users to hone their skills before potentially investing in more advanced, professional-grade equipment.

Therefore, a budget laser engraver and cutter can be an excellent choice for those wanting to explore the world of laser cutting and engraving without breaking the bank.

Exploring the Advantages of Laser Engraving and Cutting

Laser engraving and cutting offer several advantages over traditional methods of engraving and cutting. First and foremost, they provide a high degree of accuracy and precision, allowing for intricate detail and complex designs. This is particularly useful in industries where fine detail is vital, such as jewelry making or electronics manufacturing.

Secondly, laser engraving and cutting are non-contact processes, meaning the laser beam does not physically touch the material it is engraving or cutting. This eliminates the risk of material distortion or damage, ensuring a higher-quality finish and greater consistency across multiple pieces.

Moreover, laser engraving and cutting are highly versatile and capable of working with a wide range of materials including wood, metal, glass, and plastic. They can be used to create a variety of products, from personalized gifts and promotional items to industrial parts and components.

Lastly, laser engraving and cutting are faster and more efficient than traditional methods. They can complete detailed designs in a fraction of the time, improving productivity and lowering production costs. This makes them a cost-effective option for businesses of all sizes, from small craft businesses to large manufacturing plants.

In conclusion, the benefits of laser engraving and cutting make it a compelling choice for businesses and individuals wanting to deliver high-quality, personalized products efficiently and cost-effectively.

Comparing Affordable Laser Engravers for 3D Printing

When comparing affordable laser engravers for 3D printing, there are several key aspects to consider.

Ortur Laser Master 2: This laser engraver is widely recognized for its reliability and robustness, featuring a large engraving area and a high-power laser. With adjustable power and speed settings, it offers flexibility for a variety of projects. However, some users report difficulty with assembly and setup.

NEJE Master 2S Max: NEJE’s offering stands out for its advanced safety features, such as motion detection and emergency stop. It also boasts a high-resolution laser and a large work area, though it can be more expensive than other models.

ATOMSTACK A5 Pro: This model is praised for its ease of use and assembly, making it a popular choice for beginners. It offers reliable performance with a moderate engraving area but may lack some versatility compared to other models.

Each of these laser engravers has its strengths and potential drawbacks, and the best choice will depend on the specific needs and budget of the user.

Understanding the Integration of Laser Modules with Other Tools

Integrating laser modules with other tools can extend the versatility and utility of a given device, opening up new possibilities for creation and customization. For instance, integrating a laser module with a 3D printer allows for engraving and cutting functions alongside additive manufacturing. Such a combination not only saves space but can also potentially speed up the production process by eliminating the need to move workpieces between separate machines.

However, it’s crucial to consider the compatibility of the laser module with the host device. Factors such as power requirements, control software, and mounting mechanisms all play a role in determining a successful integration. Furthermore, the safety aspects of using a laser module should not be overlooked. Proper safety measures, including work area enclosures, eye protection, and automatic shutoffs, should be implemented to prevent accidents and ensure a safe working environment.

In essence, the integration of laser modules with other tools is a promising approach for the future of manufacturing and hobbyist projects, enabling a high degree of flexibility and efficiency. But this comes with a responsibility to understand and manage the technical and safety considerations that such integration entails.

Assessing the Capabilities of Budget Laser Spot Solutions

Budget laser spot solutions are seeing a rise in popularity due to their affordability and diverse utility. They offer a balance between cost and functionality, enabling users to enjoy the benefits of laser technology without a significant investment. However, the capabilities of these solutions are often limited in comparison with their higher-priced counterparts.

For instance, while budget laser solutions may be effective for simple tasks such as spot marking or engraving on certain materials, they might struggle with more complex applications requiring high precision or power. Similarly, the material range these lasers can work with is usually narrower, and their operational lifespan could be shorter due to the use of lower-cost components.

Moreover, these budget solutions often lack advanced features such as power modulation, real-time tracking, and automated error detection, which are common in premium models. Despite these limitations, budget laser spot solutions are a commendable option for hobbyists and small-scale operations, provided users understand and accept the trade-off between cost and capability.

Exploring the Versatility of Ortur Laser Master Series

The Ortur Laser Master Series exhibits impressive versatility for a product in the budget range, making it a popular choice among hobbyists and small-scale manufacturers. Its strengths lie in its user-friendly interface and solid basic functionality, which includes precise engraving and cutting for a variety of materials like wood, leather, and certain plastics. The Ortur Laser Master can achieve a respectable engraving speed of up to 3000mm/min and a cutting speed of up to 600mm/min, with an adjustable power range from 36 to 7 watts. These features, combined with the added advantage of being a compact and lightweight model, make the Ortur Laser Master Series an excellent entry point into the world of laser applications. However, like other budget laser solutions, it may not perform as well on tasks that require high precision or power, and its operational lifespan could be shorter due to the use of lower-cost components.

Tips for Using a Budget Laser Cutter and Engraver

When using a budget laser cutter and engraver, it’s essential to prioritize safety. Always wear protective eye gear when operating the device, as laser beams can cause serious eye injury. Work in a well-ventilated area to prevent inhalation of potentially harmful fumes produced during engraving or cutting.

Next, maintain the cleanliness of your machine. Regularly clean the laser’s lens following the manufacturer’s instructions to ensure optimal functionality. Dust and debris can cause the lens to heat up, leading to potential damage or decreased effectiveness.

Also, monitor your device’s temperature. Budget laser cutters often lack efficient cooling systems, so it’s vital to allow the machine ample time to cool between tasks.

For the best results, use suitable materials. Not all materials are safe or effective for laser cutting or engraving. Always refer to the manufacturer’s recommendations and do a small-scale test before undertaking a large project.

Lastly, keep in mind the limitations of a budget laser cutter. While these machines offer excellent value for hobbyists and small-scale manufacturers, they may not deliver the same precision, power, or longevity as their high-end counterparts. With realistic expectations and proper maintenance, however, a budget laser cutter can be a valuable tool for a wide range of creative endeavors.

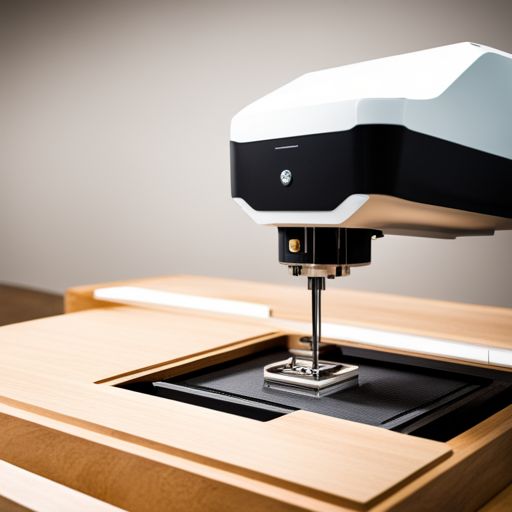

Understanding the Laser Head and Its Functionality

The laser head is a critical component of any laser cutter and engraver machine. It’s the part of the device that emits the concentrated beam of light, or laser, that carries out the cutting or engraving process. The laser head typically consists of a laser diode, a collimating lens, and a focusing lens.

The laser diode generates the laser light, and its power output directly impacts the machine’s cutting and engraving capabilities. The collimating lens then aligns the laser light into a straight beam, ensuring maximum efficiency and precision. Finally, the focusing lens concentrates the laser beam onto the material surface, inducing the high temperatures necessary for cutting or engraving.

Adjusting the laser head’s position can help control the engraving or cutting depth. It’s crucial to align the laser head properly for the best results. Misalignment can cause the laser beam to focus incorrectly, leading to uneven cutting or engraving. Regular maintenance and cleaning are necessary to keep the laser head in optimal condition and prolong its lifespan.

Understanding how the laser head functions can help users operate their laser cutter and engraver more effectively, troubleshoot potential issues, and maintain the device to ensure consistent performance.

Assessing Ways to Optimize Laser Power Efficiency

Optimizing laser power efficiency is crucial for enhancing performance and prolonging the lifespan of the device. The first step to achieve this is by regulating the power levels suitable for different materials. Soft materials may require a lower power level, while hard materials may need higher power. Overuse of power can lead to unnecessary wear and tear on the machine and inefficiencies in the cutting or engraving process.

Next is the use of good-quality lenses and mirrors, tuned to the laser’s wavelength. They can significantly improve laser power efficiency by ensuring maximum light transmission and reducing power loss.

Thirdly, maintaining an optimal focus of the laser beam is essential. An incorrectly focused laser can lead to inefficient cutting or engraving, requiring more power for the same task. Regular checks and adjustments of the beam focus can lead to substantial power savings.

Lastly, the cleanliness of the laser cutter plays a vital role in power efficiency. Dust and debris on the laser head or within the device can diminish the laser’s power, leading to subpar performance. Regular cleaning and maintenance help prevent this and keep your laser cutter working at its best.

In conclusion, understanding the device, maintaining good operating practices, and regular upkeep all contribute to optimizing the laser power efficiency.

Exploring the Use of Acrylic and Other Materials in Laser Engraving

Acrylic is a popular material choice in laser engraving due to its versatility, durability, and the high-quality finish that can be achieved. The laser can precisely cut or etch intricate designs into acrylic, creating clean and polished edges that require little to no post-processing. The level of engraving detail possible depends on the acrylic’s thickness and the laser’s power.

In addition to acrylic, other materials frequently used in laser engraving include wood, glass, leather, and certain metals. Wood is favored for its organic aesthetic and the beautiful contrast between the burned and unburned areas that engraving can produce. Glass and certain metals can also be engraved with a laser, although they typically require a coating to be applied beforehand to achieve the best results. Leather, both real and synthetic, can be engraved to create intricate patterns or text, with different effects achieved by varying the laser’s power and speed.

Choosing the right material for laser engraving depends largely on the desired outcome and application. By understanding the unique properties of each material, one can optimize the laser’s settings to achieve the best engraving results. In the next section, we will delve into the specifics of engraving each of these materials and provide some best practice guidelines.

Comparing Budget Laser Engraving Machines for Precision Work

When considering budget laser engraving machines for precision work, there are a variety of options available. Below are comparisons of a few popular models.

- Ortur Laser Master 2: This model is known for its versatility and cost-effectiveness. The Laser Master 2 offers a 32-bit motherboard with an STM32 chip that promises a faster engraving speed and high precision. However, the lack of an enclosure can lead to safety issues, hence it’s crucial to operate it with caution.

- NEJE Master 2S: The NEJE Master 2S is a compact and durable model, featuring a protective shield to prevent laser exposure and ensure safety during operation. It provides a fine engraving precision of around 0.075mm, making it suitable for intricate designs. However, its smaller workspace might be a limitation for larger projects.

- FoxAlien LE-4040: This machine stands out with its large engraving area and powerful laser. Although slightly pricier than the previous options, the LE-4040 ensures high-precision engraving and is compatible with a wide range of materials.

In conclusion, the choice of a budget laser engraving machine largely depends on the specific requirements of your projects. Careful consideration should be given to factors such as workspace size, precision, safety features, and material compatibility.

Understanding Air Assist and Cooling Mechanisms in Budget Laser Cutters

Air assist and cooling mechanisms are pivotal components in budget laser cutters to ensure both the quality of work and the longevity of the machine. The Air Assist feature primarily functions to combat the risk of fire ignited by the heat of the laser, by blowing a constant stream of air on the cutting surface. This not only helps to keep the area cool, minimizing heat damage to the material but also blows away debris that could interfere with the cutting process. Different machines may have adjustable air assist settings, allowing you to control the airflow based on the material being engraved.

On the other hand, Cooling Mechanisms are crucial in preventing the laser’s tube from overheating during operation. Laser cutters typically employ water or air-cooled mechanisms. Water-cooled systems, though initially more expensive and requiring a separate water chiller, are generally more effective in maintaining optimal operating temperatures, thus prolonging the lifespan of the laser tube. Air-cooled systems are more common in budget options, being more portable and easier to maintain, but may not be sufficient for extended use.

In conclusion, understanding these mechanisms and how they function within a laser cutter can greatly influence the performance, longevity, and safety of the device.

Frequently Asked Questions

Q: What is the best laser cutter for 2023?

A: The Ortur Laser Master 2 Pro is considered one of the best laser cutters for 2023, offering professional quality at an affordable price.

Q: Are there any cheap laser engravers available in the market?

A: Yes, there are various cheap laser engravers available, catering to every budget and offering different features for engraving and cutting.

Q: How do I choose the best cheap laser engraver?

A: When choosing the best cheap laser engraver, consider factors such as engraving and cutting capabilities, wattage, work area, and overall build quality to find the most suitable option for your needs.

Q: What are the advantages of using a laser cutter for engraving wood?

A: Laser cutters provide precision and intricate detailing when engraving wood, making them a popular choice for woodworking and creating detailed designs on wooden surfaces.

Q: Can a laser cutter cut through thick wood?

A: Yes, certain laser cutters with higher wattage are capable of cutting through thick wood, providing efficient and precise cuts for various woodworking projects.

Q: Is it possible to engrave on clear acrylic using a laser cutter?

A: Yes, laser cutters can engrave intricate designs on clear acrylic, creating stunning visual effects and adding personalized details to acrylic materials.

Q: What is the difference between a diode laser engraver and a CO2 laser engraver?

A: Diode laser engravers are often more compact and suitable for smaller projects, while CO2 laser engravers are known for their power and capability to work with a wider range of materials.

Q: What is the best laser engraver for professional use?

A: The Ortur Laser Master 3 is highly recommended for professional use, offering advanced features and precision for professional-grade laser engraving and cutting.

Q: Are there any laser cutters suitable for entry-level users?

A: Yes, there are laser cutters designed for entry-level users, providing user-friendly interfaces and basic features to introduce beginners to the world of laser cutting and engraving.

Q: Can a laser cutter be used for engraving thin wood?

A: Absolutely, laser cutters are ideal for engraving intricate designs on thin wood, offering precise detailing and customization for various woodworking projects.

References

- Affordable Laser Cutters in 2023 – TechRadar: This TechRadar article provides an up-to-date comparison of affordable laser cutters on the market in 2023, with a focus on features, pros and cons, and price range. It’s useful for readers seeking an overview of budget-friendly options.

- Laser Cutting Basics – ScienceDirect: An academic article from ScienceDirect that explains the fundamental principles of laser cutting. The paper thoroughly discusses the process, types of lasers used, and key factors to consider, contributing to a comprehensive understanding of laser cutters.

- Affordable Laser Cutting with Medium Power – IEEE Xplore: This paper from IEEE presents a study on the performance of medium-power, affordable laser cutters, providing technical insights into their efficiency and applications.

- XYZ Laser Cutter Review – Make Magazine: A thorough review of an affordable laser cutter model from Make Magazine, providing hands-on insights and practical tips.

- Orion Motor Tech Laser Cutter- Manufacturer Website: The official website of Orion Motor Tech, a known manufacturer of budget laser cutters. The site provides detailed product specifications and customer reviews.

- Understanding Laser Cutter Specs – LaserGods Blog: An informative blog post that explains the various specifications of laser cutters and how to interpret them, making it easier for buyers to make informed decisions.

- Laser Cutting for Dummies – Amazon: A beginner-friendly guidebook available on Amazon, covering basic operation, safety procedures, and maintenance tips for laser cutters.

- Laser Cutter Safety and Regulations – OSHA: The OSHA guidelines on laser cutter safety provide critical information on legal safety requirements and best practices.

- Laser Cutting Forum – Reddit: An active forum where users discuss various topics related to laser cutting, including advice on affordable models, troubleshooting tips, and creative project ideas.

- Affordable Laser Cutting: A Green Technology – Journal of Cleaner Production: This academic paper discusses the role of affordable laser cutting in promoting sustainable manufacturing practices.

Recommended Reading: CNC Knife Cutting Machine