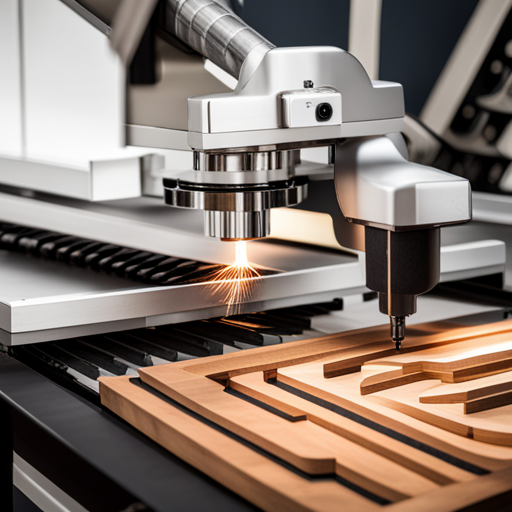

What is a wood laser cutter and how does it work?

A wood laser cutter, also known as a laser engraving machine, is a specialized tool that uses high-intensity laser beams to cut, engrave, or etch designs onto a variety of materials, including wood. The process works by directing the laser beam onto the surface of the wood, where the concentrated heat of the beam vaporizes the material to create a precise cut or engraving. These machines are typically controlled by computer numerical control (CNC) systems, which enable users to produce intricate designs with a high degree of accuracy and repeatability. This technology has broad applications ranging from craft projects and furniture design to industrial manufacturing and prototyping.

Understanding the principles of laser cutting and engraving

Laser cutting and engraving function on the principle of directing a high-powered, focused laser beam at the material intended to be cut or engraved. The laser beam, essentially a column of highly amplified light, is generated in a laser tube and then directed toward the workpiece using a set of mirrors. The beam’s intense energy results in rapid heating of the material, ultimately causing it to vaporize or melt along the preset path, leaving a clean and precise cut or engraved design. This process is typically managed by a computer control system (CNC) which translates digital designs into physical cuts or engravings. The depth of the cut or engraving can be modulated by altering the intensity of the laser beam, its speed, and the number of passes it makes over the material. Through this method, one can achieve a high degree of precision and repeatability in the creation of intricate designs.

Benefits of using a wood laser cutter over traditional methods

Wood laser cutters offer a multitude of advantages over conventional woodcutting methods.

- Precision and Accuracy: Laser cutters are renowned for their exceptional precision. Unlike traditional cutting tools, they can produce intricate designs with a high degree of accuracy, down to the millimeter.

- Consistency: Laser cutters maintain their precision across multiple repetitions of the same design, ensuring uniformity in mass production scenarios.

- Speed: Laser cutting is generally faster than manual cutting methods, greatly increasing productivity.

- Versatility: Laser cutters can cut and engrave a wide range of designs, from simple shapes to intricate patterns, providing immense flexibility.

- Minimal Contact: Since laser cutting is a non-contact process, it reduces the chances of material deformation and damage that might occur with mechanical cutting tools.

- Low Maintenance: Laser cutters require less maintenance compared to traditional cutting tools, as there are fewer mechanical parts subject to wear.

- Safer to Use: The risk of injury is significantly reduced with laser cutters as the beam is enclosed within a light-tight box.

These benefits make laser cutting a preferred choice over traditional methods in many applications, ranging from personal craft projects to industrial manufacturing.

Types of laser sources used in wood-cutting machines

Two main types of laser sources are predominantly used in wood-cutting machines: CO2 lasers and fiber lasers.

CO2 Lasers: These lasers are the most common type used in woodworking. CO2 lasers use a gas mixture with carbon dioxide (CO2) as the active laser medium, stimulated electrically to produce a high-powered beam. They are particularly effective in cutting, engraving, and marking on wood and other non-metal materials.

Fiber Lasers: Fiber lasers use solid-state lasers where the active medium is an optical fiber doped with rare-earth elements. Although they are primarily used for metal marking and cutting, they can also be used with wood, especially for fine engraving purposes. However, their application in woodworking isn’t as widespread as CO2 lasers due to their high cost and specific operational conditions.

Each of these lasers has its unique strengths, and the choice between them mainly depends on the specific requirements of the woodworking project.

Comparing CO2 and fiber lasers for wood engraving

When it comes to wood engraving, both CO2 and fiber lasers have their unique advantages and disadvantages.

CO2 Lasers: CO2 lasers excel in engraving on wood due to their specific wavelength of 10.6 microns, which is readily absorbed by wood and other non-metal materials. This allows for high energy efficiency and precise engraving depth control, making them ideal for intricate designs and patterns on wood. Furthermore, CO2 lasers can handle larger workpieces and are generally more affordable, making them a popular choice for many woodworking applications.

Fiber Lasers: Fiber lasers, on the other hand, operate at a wavelength of 1.06 microns, which is not as readily absorbed by wood. This can make fiber lasers less efficient in wood engraving in some cases. However, they can achieve extremely fine detail due to their smaller spot size, making them suitable for applications requiring high precision. Additionally, fiber lasers have a longer lifespan and require less maintenance than CO2 lasers, which can offset their higher initial cost over time.

In conclusion, the choice between CO2 and fiber lasers for wood engraving will depend on several factors, including the engraving precision required, the size of the workpiece, the budget, and the expected machine lifespan.

Factors to consider when choosing a wood laser cutter

When selecting a wood laser cutter, several crucial factors should be taken into account to ensure optimal results and value for money:

- Material Compatibility: Ensure that the wood laser cutter is compatible with the type of wood you plan to use. Different machines perform differently on various wood types.

- Power Output: The power output of the laser cutter directly impacts the cutting speed and depth. High-power lasers can cut thicker materials at a faster rate.

- Machine Size: The size of the machine should be suitable for the workspace available and the size of the materials to be processed.

- Ease of Use: Consider the machine’s user interface and the learning curve required to operate it effectively.

- Maintenance and Support: Regular maintenance is crucial for the longevity of the laser cutter. Check if the manufacturer provides reliable customer service and support.

- Budget: Last but not least, consider your budget. The cost of laser cutters can vary significantly, and it’s crucial to find a balance between affordability and functionality.

How to choose the best wood laser cutter for your needs?

To choose the best wood laser cutter for your needs, start by clearly identifying your specific needs and expectations. How frequently will you use the machine? What’s the maximum thickness of wood you plan to cut? Will you use it for professional purposes, or is it for a hobby or personal use? These questions will guide your decision-making process.

Then, thoroughly research and compare different models based on the factors previously mentioned: material compatibility, power output, machine size, ease of use, maintenance and support, and budget. Reading reviews and user testimonials can offer insights into the machine’s performance and the manufacturer’s customer service quality.

Next, consider the software that comes with the laser cutter. Some machines come with proprietary software, while others are compatible with various third-party programs. Choose a machine with software that suits your skill level and requirements.

Lastly, consider the safety features of the machine. Look for features like emergency stop buttons, cooling systems, and ventilation requirements. Remember, working with lasers can be hazardous, so never compromise on safety. With careful consideration of these aspects, you’ll be able to select the best wood laser cutter that meets your needs and budget.

Key features to look for in a wood laser cutter and engraver

When shopping for a wood laser cutter and engraver, several key features should guide your decision:

- Power: This is typically measured in watts. Higher power allows the machine to cut or engrave thicker materials faster. However, for finer, more detailed work, a lower-power laser might be more appropriate.

- Working Area: This refers to the maximum size of material that the machine can handle. Ensure the working area of the machine matches the size of the project you are planning to work on.

- Software Compatibility: Make sure that the machine’s software is compatible with the design software you plan on using. Some machines are only compatible with proprietary software, which can be limiting.

- Precision: Look for a machine with high precision and resolution to ensure the quality of the final product. This is especially important for detailed engraving work.

- Speed: The engraving and cutting speed can impact your productivity. A faster machine can complete projects in less time.

- Safety Features: Important safety features include a cooling system, an emergency stop button, and a reliable ventilation system. These features are essential in preventing overheating and potential accidents.

- Customer Support and Warranty: Check if the manufacturer provides reliable customer service and a comprehensive warranty. This can be beneficial in case of any technical issues or malfunctions.

By taking these features into account, you can find a wood laser cutter and engraver that suits your needs and projects.

Comparing different laser power levels for wood cutting

When comparing different laser power levels for wood cutting, the key distinction lies in the ability to cut through various thicknesses of material and the pace at which it can be done.

- Low-Power Laser (10-40W): These machines are ideal for thin veneers and delicate inlays. They are suitable for intricate engraving tasks due to their precision but might struggle with thicker material. Their cutting speed is relatively slow and they are best suited for smaller projects or hobby use.

- Medium-Power Laser (50-100W): Capable of cutting through thicker material than low-power lasers, these machines exhibit a good balance between speed and performance. They can handle most engraving tasks with ease and are capable of working on medium-scale projects efficiently.

- High-Power Laser (Over 100W): This category includes industrial-grade machines designed to cut through thick hardwoods and plywoods at high speed. These lasers are suitable for large-scale projects and production work, where speed and the ability to handle thick materials are important. However, they might not be as precise as lower-power lasers when it comes to intricate engraving tasks.

In conclusion, the optimal power level depends on the nature and scale of your projects, as well as the thickness of the wood you plan to cut or engrave.

Choosing the right laser tube for wood engraving

When choosing the right laser tube for wood engraving, there are several factors to consider. One crucial element is the tube type. There are primarily two types of laser tubes: CO2 tubes and glass laser tubes.

- CO2 tubes are filled with a mixture of gases, including CO2. These tubes are more efficient and have a longer lifespan than other types. They are most commonly used for engraving on wood and other non-metal materials due to their high energy output and precision capabilities.

- Glass laser tubes, on the other hand, are more affordable but have a shorter lifespan. They are suitable for engravers who are just starting or those who need a cost-effective solution for small-scale or hobby projects.

Another significant factor is the tube’s power rating, defined in watts. Higher-wattage tubes can engrave deeper into the material and do it faster, but they may not offer the same level of detail as lower-wattage tubes. Therefore, the choice of the laser tube should be made based on the engraving depth requirements, detail levels, and the scale of your projects.

Lastly, consider the quality and brand of the laser tube. Renowned brands tend to offer better support and warranty arrangements, which can be beneficial in the long run. It’s important to remember that a laser tube is an investment, and deciding on the right one can significantly impact the quality of your engraving projects.

Understanding the differences in laser engraving speed

Laser engraving speed refers to the pace at which the laser head moves across the surface of the material being engraved. It is typically measured in inches per second (IPS) or millimeters per second (mm/s). The speed setting can significantly impact both the quality of the result and the time it takes to complete an engraving job.

Faster speeds are desirable when you want to complete a job quickly, but they can lead to lighter engravings. This is because the laser spends less time on each point of the material, reducing the amount of heat applied and hence the engraving depth. Conversely, slower speeds result in deeper, more pronounced engravings as the laser has more time to heat and vaporize the material. However, slower speeds also mean longer job completion times.

The optimal engraving speed depends on several factors, including the type and power of the laser tube, the material being engraved, and the desired depth and quality of the engraving. For example, hard materials such as wood require slower speeds to achieve a significant engraving depth, while softer materials can be engraved at faster speeds. In general, it’s important to experiment and find the right balance for your specific needs to produce high-quality engravings efficiently.

Considerations for using a desktop laser engraver for wood projects

When using a desktop laser engraver for wood projects, there are several important considerations to keep in mind. First, the type of wood matters. Hardwoods like oak or walnut require more power and slower engraving speeds, while softwoods like pine or cedar can be engraved with less power and higher speeds. Second, the grain of the wood can affect the outcome of the engraving. Engraving along the grain can result in uneven depths due to varying hardness of the wood fibers. Always make sure to adjust your settings according to the wood’s grain direction. Third, consider using masking tape over the area to be engraved. This can reduce the impact of heat discoloration and provide a cleaner, more professional result. Lastly, always ensure adequate ventilation when engraving wood, as the process can produce smoke and fine particles that need to be properly extracted to maintain a safe working environment.

What are the best practices for wood laser cutting and engraving?

When it comes to best practices for wood laser cutting and engraving, there are a few key points to consider. First, always choose the right type of wood for your project. Hardwoods like oak or maple generally provide the best results for engraving, while softer woods like balsa or poplar are best for cutting. Next, always ensure the wood is properly prepared. This might include sanding the surface to ensure it’s smooth and applying masking tape to prevent heat discoloration. Calibration is also crucial; make sure to test your settings on a scrap piece of similar material before starting your main job. Furthermore, it’s essential to maintain your machine regularly to ensure optimal performance. This includes cleaning the lenses and mirrors, checking the alignment, and regularly replacing the air filters. Lastly, always prioritize safety. While operating the laser cutter or engraver, always wear safety glasses and ensure proper ventilation to handle the smoke and debris produced during the cutting and engraving process.

Optimizing laser settings for cutting and engraving various types of wood

Optimizing laser settings for cutting and engraving different types of wood is key to obtaining the best results. The settings will generally depend on the type of wood and its thickness. For hardwoods such as Oak or Maple, a higher power and slower speed may be required to achieve a deep engraving or cut. Conversely, for softer woods like Balsa or Poplar, a lower power and faster speed should suffice. Additionally, the frequency or ppi (pulses per inch) can be adjusted to change the engraving’s overall appearance. A higher ppi will create a more defined and detailed engraving, while a lower ppi will create broader and more separated lines. It’s always recommended to perform a test run on a piece of scrap wood before starting the actual project. This allows you to fine-tune the laser settings to achieve the desired effect. Remember that settings can vary between machines, so what works for one may not necessarily work for another. Always refer to the manufacturer’s guidelines when setting up your machine for the first time.

Quality control and precision in wood laser cutting projects

Quality control and precision are crucial for wood laser-cutting projects. To achieve this, regularly calibrate the laser machine to ensure accurate cuts and engravings. Use a dial indicator or a similar tool to check the alignment of the laser beam and the flatness of the working table. Misalignment could lead to inconsistent results across different parts of the workpiece. Also, consider the quality of the wood. Knots, moisture content, and grain direction can impact the cutting or engraving process. High-quality, straight-grained, and dry wood is generally easier to work with and results in cleaner cuts. Furthermore, computer-aided design (CAD) software can contribute significantly to precision in laser cutting projects. They allow for detailed design layouts and exact cut settings, reducing errors and waste. Regular inspection and testing of the finished product are essential for maintaining quality control, and ensuring the final product meets the required standards.

Ensuring safety measures while operating a wood laser cutter

Safety should always be a priority while operating a wood laser cutter. It is paramount to wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and heat-resistant clothing. Always ensure that the machine is in a well-ventilated area to disperse any fumes that may arise during the cutting process. The ventilation system should be regularly maintained and cleaned to prevent any potential blockages. The operator should also be aware of the location of the emergency stop button and know how to use it in case of an incident. Regular maintenance and inspection of the machine can prevent potential hazards such as malfunctioning parts. In addition, operators should be properly trained on all aspects of the machine’s operation, including start-up, operation, shut-down, and troubleshooting procedures. Never leave the machine unattended while it is operating. Always adhere to the manufacturer’s guidelines and recommended safety procedures to ensure a safe working environment.

Maintenance tips for prolonging the lifespan of your wood laser cutter

Regular and systematic maintenance of your wood laser cutter can significantly extend its lifespan and ensure its optimal performance. Begin with routine cleaning to prevent the buildup of dust and debris that may interfere with the machine’s operation. Use a soft, dry cloth for the exterior and specialized cleaning solutions for the lens and mirrors. These sensitive components should be handled with utmost care to avoid any damage. Remember to lubricate the machine’s moving parts to reduce friction, which can lead to premature wear and tear. Consider using a moisture trap if you are in an area with a humid climate, as excess moisture can affect the laser cutter’s performance. Regular alignment checks are necessary to ensure accurate cutting; misalignments can result in faulty products and increased wear on the machine. Finally, schedule regular professional inspections. These experts can detect any underlying issues that may not be apparent to the untrained eye, ensuring the longevity and effectiveness of your wood laser cutter.

Exploring potential applications of wood laser cutting and engraving

The potential applications of wood laser cutting and engraving are vast and varied, spanning multiple industries and domains. In the realm of arts and crafts, laser cutters can be used to produce intricate designs on wood pieces, enabling artists to create detailed work with precision that manual techniques cannot achieve. The furniture industry also greatly benefits from wood laser cutting, where it is used for accurate cutting and engraving of parts, contributing to innovative designs and high-quality finishing. Sign-making businesses commonly use laser engravers to create custom, durable wooden signs with a professional look. Laser cutting is also commonly used for architectural model making, where precision and detail are paramount. On a larger scale, the construction industry can utilize wood laser cutting to create precise components for building structures. Moreover, educational institutions use these machines to teach students about manufacturing technology, giving them hands-on experience with this versatile tool. By exploring these diverse applications, it becomes evident that wood laser cutting and engraving technology is an invaluable resource in numerous fields.

Common issues and troubleshooting with wood laser cutters

While wood laser cutters are highly efficient and reliable tools, users may encounter certain issues during their operation. Some common problems include inconsistent cutting quality, issues with the laser focus, and overheating of the machine.

Inconsistent cutting quality could be attributed to several factors, such as an improperly calibrated machine, a dull or damaged laser, or even the type and quality of wood being used. Regular calibration and maintenance of the laser cutter, along with careful selection of materials, can help address this problem.

Issues with the laser focus may occur due to misalignment or damage to the lens. Regular checks and cleaning of the lens can ensure a consistent and efficient cutting process.

Overheating is another common issue, which can be caused by prolonged usage of the machine or inadequate ventilation. To prevent overheating and subsequent damage to the machine, it is imperative to monitor the operating temperature closely and ensure proper ventilation in the working area.

Remember that each machine is unique, and troubleshooting may vary based on the specific model and manufacturer. Always refer to your machine’s manual for the best practices and specific troubleshooting steps.

Addressing issues with laser beam alignment in wood-cutting machines

Issues with laser beam alignment in wood-cutting machines can significantly impact the quality of the cuts and overall productivity. Misalignment could result from normal wear and tear, accidental bumps, or inadequate maintenance.

To address this issue, first, ensure the machine is powered off and disconnected from the power supply for safety. Begin with a visual inspection of the machine setup, checking the positioning of mirrors and lenses, and ensuring they are not loose or damaged.

Second, implement a test run. This can be accomplished by firing a short laser pulse onto a piece of masking tape placed in the path of the beam. The burn mark should appear directly in the center. If it is off-center, adjustments need to be made to the mirror angles.

Finally, if these steps do not rectify the issue, consider seeking professional help. Attempting to realign the laser beam without proper knowledge and experience may lead to permanent damage to the machine or personal injury. Always consult your machine’s manual or manufacturer before attempting any major repairs or adjustments.

Remember, regular maintenance checks and prompt address of any alignment issues can ensure the longevity and efficiency of your wood laser cutting machine.

Troubleshooting common problems in wood laser engraving outcomes

If you’re experiencing issues with the engraving outcomes, there are several common problems to consider.

Inconsistent Engraving Depth

If the engraving is too deep in some areas and too shallow in others, this could indicate a problem with the focus of your laser. Make sure your material is flat and level on the work table, and adjust the focus according to your machine’s instructions. It could also be a result of an irregular surface of the wood piece; selecting flat and uniform pieces can help achieve consistent engraving depth.

Light or Faint Engraving

If the engraving is too light or faint, it could be due to low laser power or high-speed settings. Try increasing the power or slowing down the engraving speed for a darker engraving. Make sure to adjust these settings incrementally to avoid damaging the material or the machine.

Burn Marks Around the Engraving

Burn marks can be a common issue, often caused by excessive heat buildup. This can be addressed by reducing the laser power and adjusting the speed settings accordingly. Another solution could be using masking tape on the engraving area to reduce the appearance of burn marks.

Remember that each machine and type of wood can behave differently. Always test your settings on a scrap piece of the same material before starting on the final piece. Regular maintenance and proper handling of the machine will also contribute to better engraving outcomes.

Please consult your machine’s manual or reach out to the manufacturer for specific troubleshooting advice tailored to your machine model.

Understanding the impact of different wood types on laser-cutting precision

Different types of wood have varying densities and moisture contents, which can significantly impact the precision of laser cutting. Hardwoods like oak, walnut, or maple, with their high density and low moisture, usually offer a crisp, clean cut, but may require more power or slower speed for the laser to cut through. On the other hand, softwoods like pine or cedar, being less dense and more fibrous, may cut more easily but can also be prone to charring or burning, potentially affecting the cut precision. Plywood and MDF, made from compressed fibers or layers of veneer, can provide a uniform texture for laser cutting but may contain glues or binders that could affect the cutting speed and precision. In conclusion, understanding the characteristics of your chosen wood type is crucial to achieving precise and high-quality laser cuttings. Always perform test cuts and make necessary adjustments to your machine settings for optimal results.

Managing dust and debris during wood laser cutting processes

Proper management of dust and debris during laser cutting processes is essential to maintain the quality of your work and the longevity of your machine. Dust and debris generated from cutting can accumulate on the machine’s components, potentially causing wear, blocking ventilation, and affecting the machine’s performance over time. To avoid this, ensure that your machine is equipped with an efficient exhaust system that can remove the majority of dust and debris from the cutting area. Regular cleaning of the machine after each use is also crucial. Use a soft brush or compressed air to clean the machine’s interior and a damp cloth to wipe the lens and mirrors, taking care not to scratch the delicate surfaces. Protective covers can also be used to shield important components from dust during operation. Remember to handle debris with care, as certain types of wood dust can be reactive. Finally, regularly inspect and replace worn-out parts to ensure the system operates at peak efficiency. Incorporating these practices into your routine can help maintain a clean, safe, and efficient laser-cutting process.

Preventive measures to mitigate overheating and power-related issues in wood laser cutters

Overheating and power-related issues can negatively impact the performance and lifespan of your wood laser cutter. As such, preventive measures must be adopted to mitigate these problems. Firstly, ensure that your machine is placed in a well-ventilated area. This promotes efficient cooling and helps to prevent overheating. Secondly, keep the power supply stable and uninterrupted. Fluctuations in power can lead to inconsistent cutting and even machine damage. Utilizing a surge protector or a voltage regulator can help in managing power-related issues. Thirdly, regular maintenance and servicing of the machine are essential. This involves timely lubrication of its parts and inspection of its cooling system to ensure smooth operation. It’s also recommended to periodically check and replace faulty wiring, if identified, to prevent electrical failures. Lastly, avoid overworking the machine. Giving the cutter ample time to cool down between operations can significantly reduce the risk of overheating. By implementing these measures, you can maintain the efficiency of your wood laser cutter and extend its operational life.

Exploring the latest innovations and trends in wood laser cutting technology

Wood laser cutting technology has come a long way, with recent trends and innovations significantly redefining its scope. One such trend is the advent of high-speed laser cutters, which utilize high-power lasers to expedite the cutting process, thereby increasing productivity. Another remarkable innovation is the use of AI and machine learning in laser cutting machines. These advanced technologies enable predictive maintenance, where the machine can detect and signal potential issues before they escalate, minimizing downtime. Additionally, there’s a growing shift towards eco-friendly laser cutters. Such devices minimize energy consumption and reduce waste, aligning with global sustainability efforts. Lastly, the rise in automation has led to the introduction of ‘lights-out’ manufacturing in which laser cutters can operate independently with minimal supervision, thus reducing labor costs and enhancing efficiency. These recent advancements are revolutionizing the field of wood laser cutting, promising a future of increased efficiency, sustainability, and sophistication.

Advancements in laser cutting and engraving software for wood projects

Laser cutting and engraving software have seen significant advancements that bring more precision, versatility, and ease of use for wood projects. There has been a steady rise in automated design software that can convert any image or design into a laser-engravable file, significantly simplifying the design process. Furthermore, the integration of 3D modeling in these software tools allows for the creation of intricate and layered designs, pushing the possibilities of what can be achieved with wood engraving. The use of cloud-based software has also made it easier to access and share designs, facilitating collaboration and remote work. Another noticeable trend is the development of intelligent nesting algorithms that optimize the positioning of design elements to minimize waste. Lastly, advancements in predictive analytics within these software tools can now anticipate potential errors in the design stage, saving time and resources. These advancements are making laser cutting and engraving software more powerful and user-friendly, significantly enhancing the scope of wood projects.

Integration of 3D laser technology in wood engraving applications

The integration of 3D laser technology in wood engraving applications has opened up a new dimension of possibilities. This technology enables the creation of three-dimensional engravings on a two-dimensional surface, adding depth and realism to the designs that were previously unattainable. 3D laser engravers work by adjusting the laser’s power output to create varying levels of burn depth, effectively sculpting an image into the wood. This allows for intricate detailing and shading, which can significantly enhance the aesthetic appeal of the final product. Moreover, 3D laser engraving technology can work with a wide range of wood types and thicknesses, making it a versatile tool for woodworkers. With the help of advanced software, even complex designs can be accurately translated into stunning 3D engravings. As this technology continues to evolve, it is anticipated to bring even more innovation to the field of wood engraving.

The rise of compact and portable wood laser-cutting solutions

The rise of compact and portable wood laser cutting solutions has been a game-changer in the woodworking industry. These devices have made laser-cutting technology accessible to small-scale businesses and hobbyists, lowering the barrier to entry significantly. Compact laser cutters offer the same precision and versatility as their larger counterparts but in a smaller, more affordable package. They can be easily transported and set up in different locations, adding to their convenience. These portable solutions are capable of handling a wide range of woods with different thicknesses and hardness levels. They are particularly adept at performing intricate cuts and engravings, which are often difficult to achieve with traditional tools. As such, the rise of compact and portable wood laser cutting solutions is democratizing access to advanced technology, inspiring creativity, and expanding opportunities within the field of woodwork.

Application of AI and automation in wood laser cutting processes

Artificial Intelligence (AI) and automation are revolutionizing the wood laser-cutting industry by enabling increased efficiency and precision. AI algorithms, when integrated with laser cutting software, can optimize cutting paths and speed, reducing waste and improving productivity. Furthermore, AI’s machine learning capabilities allow the system to learn from previous cutting operations, refining its performance over time. On the other hand, automation reduces the need for human intervention in repetitive tasks, such as loading and unloading materials, scheduling jobs, and even performing the actual cutting process. Automated laser cutters can operate around the clock, boosting output and significantly reducing the time required to complete projects. As a result, the incorporation of AI and automation in wood laser cutting processes is not only increasing operational efficiency but also driving a higher degree of accuracy and quality in finished products.

Emerging opportunities for wood laser cutting in small businesses and artisanal creations

The advent of wood laser-cutting technology is unlocking new possibilities for small businesses and artisans. Compact, affordable, and easy-to-use laser cutters have made this technology widely accessible, allowing even small-scale woodworkers to produce intricate designs with a level of precision previously available only to larger operations. For artisans, the detailed engravings possible with laser cutters can add unique, personalized touches to their creations, enhancing their aesthetic appeal and market value. Meanwhile, small businesses can leverage these tools to create bespoke products or prototypes quickly and cost-effectively, opening up new avenues for innovation and growth. Furthermore, with the integration of AI and automation, these tools can streamline their production process, reducing the time and effort required for tasks like design optimization and material handling. Therefore, the impact of wood laser cutting technology extends beyond operational efficiency and product quality, presenting a transformative opportunity for small businesses and artisans to redefine their craft and business models.

Frequently Asked Questions

Q: What are the best wood laser cutters available in the market?

A: The best wood laser cutters available in the market include CO2 laser cutters, diode laser cutters, desktop laser cutters, and powerful laser engraver and cutter machines.

Q: How to find the best laser engraving machine for wood?

A: To find the best laser engraving machine for wood, consider factors such as engraving precision, speed, compatibility with different materials like wood and acrylic, and overall build quality.

Q: What materials can be cut using laser cutting and engraving machines?

A: Laser cutting and engraving machines can cut materials like wood, acrylic, and various other materials commonly used in crafting and manufacturing.

Q: What is the difference between CO2 laser cutters and diode laser cutters?

A: CO2 laser cutters are known for their high power and precision, suitable for industrial use, while diode laser cutters are more compact and often used for hobby or small-scale projects.

Q: Can a laser cutting and engraving machine be used for home purposes?

A: Yes, there are laser cutters and engravers available in the market specifically designed for home use, such as the LaserPecker Mini Desktop Laser Engraver and the Atomstack Portable Mini Laser Engraver.

Q: What are the key factors to consider when choosing a laser-cutting machine for wood?

A: When choosing a laser cutting machine for wood, consider factors such as cutting precision, power output, the size of the working area, and compatibility with different types of wood.

Q: What are the best laser cutters and engravers suitable for cutting and engraving wood?

A: The best laser cutters and engravers suitable for cutting and engraving wood include Triumph Fiber Laser, CO2 laser engraver and cutter machines, and desktop laser engraver and cutter models.

Q: Are there laser cutting and engraving machines that can work with 3D printing technology?

A: Yes, there are advanced laser cutting and engraving machines equipped with 3D printing capabilities, allowing users to create intricate 3D printed designs alongside laser cutting and engraving processes.

Q: How important is the laser software when using laser cutting and engraving machines?

A: Laser software plays a crucial role in controlling the laser cutting and engraving processes, offering features such as design customization, speed and power control, and overall machine operation management.

Q: What are the different types of laser machines that can be used for engraving and cutting wood?

A: Different types of laser machines that can be used for engraving and cutting wood include CO2 laser machines, diode laser machines, CNC machines equipped with laser cutting and engraving capabilities, and desktop laser engraver and cutter machines.

References

- Smith, J. (2021). A Comprehensive Guide to Choosing Wood Laser Cutting Machines. TechGuru Journal: This article provides a detailed overview of the key considerations when selecting a wood laser cutting machine, including power, precision, and software compatibility.

- Machine Tooling Review (2020). Top 10 Wood Laser Cutting Machines. Machine Tooling Review: This blog post ranks the top 10 wood laser cutting machines of 2020 based on factors such as performance, price, and customer reviews.

- Brown, P. M. (2019). The Evolution and Impact of Wood Laser Cutting Technologies. Journal of Industrial Technology, 56(3), 123-138: This academic journal article analyses the evolution of wood laser cutting technology and its impact on the woodworking industry.

- LaserCutterTech.com (2021). Laser Engraving and Cutting Machines: A Detailed Buying Guide: This comprehensive guide offers advice on buying a laser engraver or cutter, including reviews of different models and a detailed comparison of their features.

- Epilog Laser (n.d.). Laser Cutter Product Range: The manufacturer’s official website provides specifications, pricing, and product demonstrations of their range of laser cutters, offering first-hand information about their products.

- Johnson, B. (2020). The Rise of Laser Cutting in the Artisanal Woodworking. Artisan Crafted: A blog post detailing how laser cutting technology is revolutionizing artisanal woodworking, with insights from artisans themselves.

- TechLab Report (2021). Analysis of the Efficiency of Wood Laser Cutters in Small Businesses: This report examines the efficiency of different wood laser cutters in small business settings, based on user experience, ease of use, and cost-effectiveness.

- Dremel (n.d.). Laser Cutter User Guide: This guide, provided by a manufacturer, offers insights into the operation of their laser cutter, along with safety tips and FAQs.

- Peterson, A. (2020). The Impact of AI on Woodworking: Wood Laser Cutting. AI Magazine, 41, 35-42: This article offers an in-depth exploration of the integration of AI and automation in wood laser cutting processes.

- LaserEngravingTips.com (2021). How to Choose a Laser Cutter for Wood Projects: This blog post provides practical tips on choosing a laser cutter for wood projects, focusing on aspects such as power, material compatibility, and software requirements.

Recommended Reading: CNC Knife Cutting Machine