Acrylic Laser Cutter

China Top Acrylic Laser Cutter

- High Precision Cutting: Dekcel laser cutters are known for their high precision cutting. We are designed with advanced technology that ensures accuracy and speed.

- Versatility: They can handle a wide range of materials including wood, fabric, leather, paper, and more.

- Ease of Use: Dekcel laser cutters are designed with user-friendly interfaces.We come with software that makes it easy to design and execute projects.

Get Our Best Quotes

Please Fill in the Form Below and Our Engineers Will Respond within 24 Hours

Home » Acrylic Laser Cutter

Introducing The Acrylic Laser Cutter From Dekcel!

The Dekcel Acrylic Laser Cutter is the perfect companion for all creative endeavors, offering high precision cutting and versatility to handle a wide range of materials. It comes with an intuitive interface and user-friendly software that make it easy to use, with excellent customer support from Dekcel available. Discover a new level of creativity with the Dekcel Acrylic Laser Cutter – start creating today!

Five Benefits of Sourcing acrylic laser cutting machine from China

- One of the biggest reasons to source your machine from China is because you’ll be able to get a high-quality machine at a fraction of the cost of what you would pay elsewhere.

- Chinese manufacturers can keep their prices low due to the lower cost of labor and materials in China, and they pass those savings on to their customers.

- When you source from China, you’ll have your pick of literally hundreds of different models and brands of acrylic laser cutting machines.

- No matter what your budget or specific needs are, you’re sure to find a machine that’s perfect for you.

- Just because Chinese machines are more affordable doesn’t mean they’re inferior in quality.

- Many Chinese manufacturers produce machines that are on par with—or even better than—their more expensive Western counterparts.

- Most Chinese manufacturers have been in business for decades and have amassed a wealth of knowledge and experience in manufacturing acrylic laser cutting machines.

- This experience means they can produce reliable, high-quality machines that meet your needs and exceed your expectations.

- When you buy from a Chinese manufacturer, you can rest assured knowing that you’ll receive excellent customer service before, during, and after the sale.

- Most Chinese companies offer 24/7 customer support, so help is always just a phone call or email away if you ever have any questions or concerns about your machine.

- As you can see, there are plenty of good reasons to consider sourcing your next acrylic laser-cutting machine from China.

- By taking advantage of the lower costs and increased selection, you’re sure to find the perfect machine for your needs—and save a lot of money in the process!

Why Dekcel's CNC Acrylic Cutting Machine is the Best Choice for Your Business

- Dekcel’s CNC acrylic cutting machine is made with high-quality materials designed to last.

- You won’t have to worry about replacing your machine anytime soon.

- With Dekcel’s CNC acrylic cutting machine, you can rest assured that your cuts will be precise.

- This is because our machine is equipped with a laser that ensures accuracy.

- One of the best things about Dekcel’s CNC acrylic cutting machine is its versatility.

- This machine can be used for various projects, making it a great investment for your business.

- When compared to other CNC acrylic cutting machines on the market, Dekcel’s machine is very affordable.

- This makes it a great option for businesses of all sizes.

- Our CNC acrylic cutting machine is easy, even if you’ve never used one before.

- This makes it a great choice for businesses that don’t have a lot of experience with these types of machines.

Best Acrylic Laser Cutter Recommend

Blogs About Acrylic Laser Cutter

The Guide To Acrylic Laser Cutter

Welcome to our comprehensive guide on Acrylic Laser Cutters. This guide is your one-stop resource for everything you need to know about this versatile tool. It’s designed to provide clear, concise, and useful information tailored to your needs.So, if you’re considering investing in an Acrylic Laser Cutter, stay tuned!

What is an acrylic laser cutter?

An acrylic laser cutter is a powerful tool used in the acrylic industry to cut sheets and materials with incredible precision. Architects, designers, sign makers, and fabricators rely on this equipment to create intricate designs. By harnessing the focused intensity of a high-powered laser beam, the acrylic laser cutter can quickly and accurately shape acrylic materials.

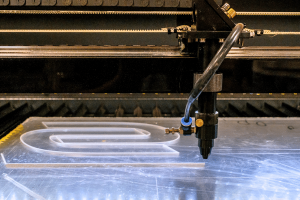

How it Works

The acrylic laser cutter works by directing a solid laser beam onto the surface of the acrylic material. This beam instantly melts and vaporizes the material, producing an exact cut. The machine utilizes CNC and CAD software to execute intricate designs, ensuring accuracy and efficiency. Safety precautions, such as specialized goggles and gloves, are essential when operating this equipment.

Benefits

The benefits of using an acrylic laser cutter are numerous. It easily handles complex designs with high precision, improving production times and efficiency. Compared to traditional cutting methods, the laser cutter can save on costs by eliminating material waste and minimizing the chance of errors that require rework.

Applications

Acrylic laser cutting has a wide range of applications across various industries. It excels at creating intricate designs of different shapes and sizes, making high-quality signage, and supporting acrylic fabrication industries. Architects and designers appreciate the precise cuts and ability to achieve complex shapes, while large-scale projects benefit from the cost-effectiveness and fast production times.

Types

Different types of acrylic laser cutters are available to cater to various user needs. There is a machine for every purpose, from small-scale projects to industrial settings. Popular styles include desktop laser cutters, hobbyist-level cutters, and large-format laser cutters capable of handling thicker and larger-sized acrylic sheets. The choice of machine depends on the user’s specific needs and intended application.

How to choose the best acrylic laser cutter?

Factors to Consider when Choosing an Acrylic Laser Cutter

The thickness of the material that the cutter can handle is one of the most important factors to consider. The cutting depth varies depending on the wattage of the laser cutter. Determining the thickness of the materials you plan to work with is essential to choosing the suitable laser cutter.

Another critical factor is wattage. The higher the wattage, the faster the cutter will work. Moreover, higher wattage allows for cutting thicker materials. That being said, higher wattage also means higher cost and maintenance.

Accuracy and precision are also crucial factors. The focal point determines the level of precision and accuracy. Automatic focusing can be very helpful to ensure consistent and accurate cuts.

Top Features to Look for in an Acrylic Laser Cutter

In addition to the factors mentioned above, other features can make your laser cutter experience more efficient and productive. Automatic focusing is a vital feature that helps ensure that your cuts are consistent and that your finished product is high quality. Another helpful feature is the rotary attachment, which provides the flexibility to engrave cylindrical and round objects.

Budget Considerations for Acrylic Laser Cutters

Acrylic laser cutters vary in price according to their specifications and features. Budget considerations include the wattage, the thickness of the materials to be cut, and the level of accuracy and precision. Generally, higher wattage and greater accuracy and precision tend to result in a higher cost.

Popular Brands of Acrylic Laser Cutters

Regarding acrylic laser cutters, there are many brands to choose from. Some popular brands include Dekcel. Dekcel is one of the leading Acrylic Laser Cutter manufacturers in China.

Reviews and Recommendations for Acrylic Laser Cutters

Before making your final decision, it’s essential to read reviews and recommendations to get an idea of the experiences of other buyers. Reviews can help identify potential problems and advantages and ensure you choose a reliable and efficient laser cutter.

In conclusion, choosing the best acrylic laser cutter involves an analysis of the factors, features, budget, and popular brands. With this guide, you can make an informed decision and ensure that you invest in a high-quality product that meets all your needs.

How does laser cut and engrave acrylic?

Preparing the acrylic for laser cutting and engraving

Before cutting or engraving acrylic with a laser cutter, it is essential to properly prepare the material to prevent damage or inconsistencies in the final product. The preparation process includes selecting the appropriate acrylic type, cleaning the surface, masking the acrylic, and positioning the material securely on the laser cutter bed. The kind of acrylic chosen depends on the project’s intended use and desired effect. Cleaning the cloth is necessary to remove oil, dirt, or debris that may affect the processing quality. Masking the acrylic surface helps to protect it from potential burns and facilitates the removal of excess waste. Positioning the material must be secure to eliminate the likelihood of it shifting during the cutting or engraving process.

Setting up the acrylic laser cutter for cutting and engraving

The laser cutter’s setting plays a significant role in achieving the desired result when cutting and engraving acrylic. The machine’s speed and power setting must be optimized to accommodate the acrylic’s thickness and density. The machine’s bed size should be adjusted to the acrylic sheet size and the cutting or engraving design. The focal point of the laser cutter is also essential, as it determines the depth and sharpness of the cuts and engravings.

Adjusting the laser settings for acrylic cutting and engraving

Acrylic cutting and engraving require different laser settings, and adjusting these settings is crucial to achieving a clean and precise cut or engraving. For cutting, the laser power needs to be set higher, and the cutting speed needs to be adjusted to maintain the quality of the edges. In contrast, the laser power needs to be set lower for engraving, and the engraving speed needs to be adjusted to ensure the engraved area’s clarity and depth. Testing the cutting and engraving settings on a small piece of acrylic before proceeding with the project to refine the ideal locations is recommended.

Tips and techniques for successful acrylic laser cutting and engraving

Apart from the technical settings, some tips and techniques for achieving successful acrylic laser cutting and engraving include proper ventilation for the machine to prevent smoke and fumes. Additionally, it is best to avoid touching the acrylic surface as it can leave fingerprints that may affect the finish. Changing the blade frequently when cutting acrylic is also recommended, as a dull knife can cause melting and charring, reducing the quality of the cut. Lastly, using a rasterized image for engraving can produce better results than a vector image.

Finishing and post-processing acrylic laser cut and engraved pieces

Once the acrylic cutting or engraving is complete, removing the masking is the first step in revealing the finished project. Sanding the edges or using a flame polisher can smooth the edges and enhance the finish. Applying a protective coating to the acrylic surface can add durability and gloss to the product. However, the layer must be compatible with the acrylic type and used carefully to avoid ruining the finished product. Following these steps can achieve a practical and aesthetically pleasing acrylic laser cutting and engraving project.

What are the different types of acrylic for laser cutting?

Overview of Acrylic Materials for Laser Cutting

When it comes to laser cutting, there are three main types of acrylic: extruded acrylic, cast acrylic, and impact-modified acrylic. Extruded acrylic is an affordable and flexible option, perfect for projects that require budget-friendly solutions. On the other hand, cast acrylic offers crystal-clear panels that provide superior precision in laser cutting. Impact-modified acrylic, or acrylic-polyvinyl chloride (PVC), combines transparency with high impact resistance.

Choosing the Right Type of Acrylic for Your Project

Selecting the right acrylic type for laser cutting depends on your project’s requirements. Extruded acrylic is ideal for affordability and flexibility, while cast acrylic excels in high precision and clarity, making it perfect for signage and display cases. If durability and strength are what you need, impact-modified acrylic is your best bet.

Pros and Cons of Using Different Types of Acrylic

Each acrylic type has its pros and cons in laser cutting. Extruded acrylic may result in rough cuts and melted edges, while cast acrylic ensures clean and precise cuts at a higher cost. Though highly durable, Impact-modified acrylic is less transparent compared to the other options, limiting its use in aesthetic applications.

Special Considerations for Laser Cutting Specific Acrylic Types

To achieve optimal results, consider the acrylic thickness and the laser wavelength. Thin sheets are prone to cracking, while heavier material may require longer cutting times. Additionally, each acrylic type requires specific laser settings. For instance, cast acrylic may require slower cutting speeds and more passes than extruded acrylic.

Examples of Projects Using Different Types of Acrylic

From DIY jewelry and keychains to commercial signage and impressive architectural features, acrylic is a versatile laser-cutting material. Extruded acrylic is excellent for creative DIY projects, while cast acrylic shines in commercial applications. Impact-modified acrylic finds its place in the medical field due to its exceptional impact resistance.

In conclusion, choosing the right acrylic type for laser cutting is crucial for project success. Consider cost, durability, precision, and aesthetics when making your decision. Understanding the properties and characteristics of each acrylic type will help you achieve outstanding results in your laser-cutting endeavors.

How to maintain and troubleshoot an acrylic laser cutter?

Regular Maintenance Tasks for An Acrylic Laser Cutter

It is crucial to perform regular maintenance tasks to maintain an acrylic laser cutter in optimal condition. These tasks include cleaning the machine regularly, lubricating moving parts, checking the alignment of the cutting bed and head, and inspecting the mirrors and lenses for dust and dirt. Properly performing these routine tasks can extend the machine’s longevity, reduce downtime, and prevent costly repairs.

Troubleshooting Common Issues with Acrylic Laser Cutters

Despite regular maintenance tasks, acrylic laser cutters may encounter common issues requiring troubleshooting. These issues may include loss of power, misalignment of mirrors and lenses, and improper calibration of the cutting head. This section will provide users with the necessary steps to identify and resolve common issues with acrylic laser cutters, reducing downtime and minimizing repair costs.

Cleaning and Cleaning Materials for Acrylic Laser Cutters

Keeping an acrylic laser cutter clean is essential in maintaining optimal performance and extending the machine’s service life. This section will provide users with guidelines on properly cleaning an acrylic laser cutter, the recommended cleaning materials, and the care to be taken when washing the machine. Proper cleaning of an acrylic laser cutter can prevent damage to the mirrors and lenses, ensure the accuracy of the cutting head, and prevent the accumulation of harmful fumes.

Replacing Parts and Components of an Acrylic Laser Cutter

Over time, parts and components of an acrylic laser cutter may wear out, requiring replacement. This section will provide users with the necessary information to identify damaged or worn parts and replace them with new ones. Information will be provided on acquiring replacement parts, the essential tools required for the replacement process, and the steps to follow when replacing parts. Properly replacing parts and components will ensure the machine’s optimal performance and extend its service life.

Professional Servicing and Repair Options for Acrylic Laser Cutters

Despite performing regular maintenance tasks, an acrylic laser cutter may occasionally require professional servicing or repairs. This section will provide information on available professional servicing options, including each option’s advantages and disadvantages and factors to consider before seeking professional servicing. Users will also be informed of available repair options, including the cost implications and how to choose the best repair option for their particular machine.

Contact Dekcel

Frequently Asked Questions

Q: What type of acrylic can be cut and engraved with a laser cutter?

A: A laser cutter can cut and engrave various types of acrylic, including clear acrylic, plexiglass, and thick acrylic sheets.

Q: What are some typical applications for laser-cut acrylic?

A: Laser-cut acrylic can be used for various applications, such as signage, displays, jewelry, model-making, architectural models, and personalized gifts.

Q: What is the best laser for cutting and engraving acrylic?

A: The best laser for cutting and engraving acrylic is typically a CO2 laser cutter. CO2 lasers are known for their versatility and ability to precisely cut through acrylic material.

Q: How does a laser cutting machine work?

A: A laser cutting machine directs a high-powered laser beam onto the surface of the acrylic material. The beam heats the material and vaporizes or melts it, creating a clean cut or engraving.

Q: What is the cutting speed of a laser cutter?

A: The cutting speed of a laser cutter can vary depending on the machine and the thickness of the acrylic material. However, laser cutters are generally faster than traditional cutting tools.

Q: Can a laser engraver engrave other materials besides acrylic?

A: Yes, a laser engraver can engrave a wide range of materials, including wood, glass, metal, leather, and plastic.

Q: What is the difference between a laser cutter and an engraving machine?

A: A laser cutter is primarily used for cutting materials, including acrylic, while an engraving machine is designed specifically for engraving designs or markings on different surfaces using a laser beam.