In the current fast-paced world, a lot of people are looking for innovative tools that can help them express themselves while on the move. This need has seen the rise in the popularity of portable laser engravers. These gadgets have completely changed how artists, designers, and enthusiasts bring their ideas into reality. What this means is that they are able to work from anywhere at any time. Additionally, these small devices give users the freedom to engrave complex patterns onto different materials like wood, leather, glass, or even metals such as steel and aluminum. They can do this with an accuracy never seen before in such machines which were too bulky for portability purposes. It doesn’t matter whether you’re new at using one or not since most models come with easy-to-use interfaces through which you can control speed levels as well as depth levels during engraving, thereby opening up infinite options when it comes down to personalization, hence sparking off creativity making them a must-have for those who want their projects to stand out.

What is a Really Portable Laser Engraver?

Describing “Portable” in Relation to Laser Engraving

When we speak of portability as it pertains to laser engraving, we mean the ability for a device to be easily moved from one place to another and used outside of the traditional workshop or studio environment. This means that an actual portable laser engraver should be light in weight, small-sized, and usually powered by batteries so that artists can bring them along anywhere they go for work. It’s not just about being compact, though; durability against traveling hassles plus versatility when dealing with different materials on the fly are other things that must be considered, too, if an engraver is going to really qualify as portable. Portability stretches creative spaces beyond physical boundaries, enabling users to realize their dreams virtually anywhere without limits.

Comparing Compact and Moveable Models: LaserPecker, Xtool, and Others

In the portable laser engraving sector, two names that can not be ignored are LaserPecker and Xtool. Both brands have many features to offer suitable for different preferences and project requirements.

LaserPecker engravers are famous for being extremely small-sized. These devices are made as lightweight as possible so that they can fit in with the creators on the move perfectly. What sets it apart is how easy they are to use – having applications that work smoothly when connected to a smartphone or laptop computer, which allows fast setup and operation. Although small in size, they do not lack accuracy; hence, they can create finely detailed engravings even on various materials.

On the other hand, Xtool is known for its versatility and strength. Although still mobile tools, they usually come with larger engraving areas than other models, plus the ability to cut through thicker materials, thus giving users more flexibility for bigger projects. They also come along with stronger software options that give more control over the engraving process, such as adjusting the power of the laser or fine-tuning the speed/depth of engravement, etc.; this makes it preferred by professionals who need high-performance levels from their devices while still being able to carry them around easily during work trips or hobbyists looking for more powerful portables.

When comparing these models against others on sale, one may consider the following parameters:

- Size & Weight– This determines how easy you can carry the device around, i.e., portability

- Battery life – crucial factor especially if doing lots of outdoor engraving where there might be no power source nearby.

- Material compatibility – The types of materials an engraver can work with e.g., wood, leather, glass or metal affects what projects could be done.

- Engraving area– Size of space where laser beam can mark into at any given time; affects how big work can be done using that particular machine.

- Software & Connectivity– How easy it is for users to connect an engraver to other devices and design projects intuitively.

- Power & Speed– Affect quality of an engraving process in terms of ability to cut through materials or detail with which engravings are made over short period.

By evaluating these aspects one will be able to choose a portable laser engraver that suits their creative needs and project requirements best thus enabling them to select a tool which complements their workflow while enhancing their capacity for bringing ideas into reality.

The Significance of Size and Weight in Portable Engraving Equipment

For professionals and hobbyists who are always shifting from one project or location to another, the importance of a laser engraver’s size and weight cannot be underestimated. Smallness in a design means that it can easily be carried around; besides being light, it makes it possible for one to start working within no time after reaching new places. This feature is crucial for customization on site, attending craft fairs or even casual engraving outside one’s usual workshop. Users increase their operational flexibility when they make size and weight among their top considerations, hence allowing them to be creative without being tied down by fixed bulky setups.

Uncovering What Handheld Laser Engravers Can Do

Handheld vs Desktop Laser Engravers: Trade-offs Explained

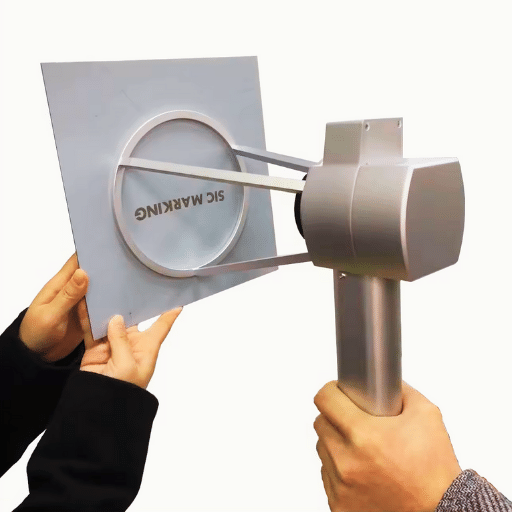

The handheld laser engraver has unmatched versatility and convenience because it allows people move freely as well as engrave objects which may not be easily reached by those using desktop models. However, this mobility often sacrifices the intensity of engraving power alongside accuracy levels that can be achieved with the latter machines. Conversely, although desktop models are usually more powerful and thereby capable of achieving finer details, they are larger in size and heavier, thus limiting their portability. Therefore, individuals should consider what matters most between these two types – anywhere ability against greater power/precision required for choosing an engraver.

New developments in portable laser devices

To make handheld lasers more manageable and precise manufacturers of the newest handheld laser technology developments have placed their focus on compactness and accuracy. By this time, there are power-regulating models that permit users to choose what power level is suitable for different materials or depths of engraving. In addition to this, batteries can now be used for longer periods due to advances made in them as well, thus reducing the frequent recharges necessary. One big step forward has been taken with smart integration, where some handheld engravers support Bluetooth connectivity alongside companion apps, too. These applications allow people to design easily and customize engraving patterns before transferring them straight into their mobile devices and then eventually streaming them onto the equipment used for engraving; such improvements save time greatly. With these new technicalities, professionals will never look at things the same way again, and neither will hobbyists because it makes one’s work even easier while being equally effective.

Assessing the Best Portable Laser Engravers on the Market

To identify which are the best portable laser engravers on the market, it is necessary to examine some essential parameters that are important for ensuring that you choose rightly according to your needs. Below is a breakdown of these parameters:

- Power and Accuracy: The greatest thing to consider is power against accuracy and how they are balanced by an engraver. Those devices which provide adjustable power settings should be sought; this will enable one work on different materials and depths while still maintaining finer details.

- Battery Life: When selecting among various models, keep in mind that the portability factor plays a big role here; hence, battery life has become one of the major considerations, too. Choose advanced batteries with extended work periods or better still those designed such as to offer hours of operation from just a single charge.

- User-Friendly: Look at the user interface as well as general ease of use especially if you have never used any before. Opt for something having intuitive controls plus smart connectivity features where possible so that transferring designs can be done easily through mobile devices like phones or tablets.

- Solidness: These tools may find themselves being used across different places thus making them less vulnerable is crucial too. Ensure they have been built using high-quality materials capable of withstanding wear and tear, thereby safeguarding your investment always.

- Smart Functions: With technology advancements came Bluetooth enabled systems together with companion apps all aimed at streamlining engraving processes thus making them friendlier to users. It would therefore help a lot in terms of workflow from design stage up until execution point if only those engravers supporting such technologies were considered during selection.

Therefore, by taking into consideration these factors, evaluating each model based on power, battery life, ease of use, durability, and smart functions will enable you to discover which among them is the best handheld laser engraver for your particular engraving needs.

Understanding High Accuracy and Rapid Engrave Features

What High Accuracy Engraving Means for Users

In industries where detail and precision are everything, high-accuracy engraving is a must-have for users. It ensures that even the most complex artwork or functional markings are produced with the least amount of error possible by duplicating intricate designs and texts clearly. This implies that fine workmanship is not only improved but also extended beyond limits previously considered achievable into areas that were believed to be unimaginable through creative design doors opened up by such precise levels among professionals as well as amateurs. Moreover, it saves materials from being wasted and time taken redoing things thereby saving on resources too while working on any project.

Comparing the Quickest Mobile Laser Etcher: Velocity vs Excellence

The trade-off between speed and quality becomes apparent when considering the fastest mobile laser etchers. Faster engraving speeds often mean that each pass takes less time, which can affect the depth and accuracy of the engraving, potentially sacrificing detail for quickness. However, there have been significant developments in engravers that manage to achieve a good balance due to advancements in laser technology and software algorithms. Precise controls and optimized power settings are now integrated into high-speed machines so that even at faster speeds, the quality of an engraving is better retained. The right machine is selected by examining project needs and being aware that for intricate designs requiring high fidelity, it may be necessary to reduce speed slightly without compromising on desired quality.

Diode Lasers’ Role in Achieving Speed as well as precision

In portable laser engraving, diodes marry precision with speed by performing seemingly conflicting functions. These lasers are famous for their small size and efficiency because they emit a very narrow beam of light which enables accurate removal of materials at high rates. Diode lasers achieve accuracy during tasks like engravings where details need to be fine by producing consistently controlled outputs so that they can give consistently, detailed outputs whenever required. In addition to this, while working on different parts of an object quickly without making any compromises on its fineness, these devices are able to heat materials rapidly through vaporization, thereby saving the time taken by other devices moving slowly over workpieces. More advanced models improve upon this harmony through the inclusion of intelligent software capable of adjusting power dynamically depending on real-time changes in speed, thus ensuring optimal performance across various materials and designs during etching processes. For both excellence and efficiency in engraving projects, diodes become tools no one should lack.

How to Choose the Correct Stuff for Your Portable Laser Engraver

The Most Suitable Materials for Engraving: Metal, Wood, Plastic and Leather

The decision about what materials are best for engraving mainly depends on the properties of those materials as well as the engraver’s possibilities. Among the most demanded metals are aluminum and stainless steel, which are known for their strength and smooth finish that can be achieved with them. Such characteristics make them perfect for manufacturing items of professional quality or creating personalized gifts. Wood is a versatile option that allows deep visible engravings that are suitable for decorative objects or custom signs. Plastics especially acrylic can be engraved with great precision in order to produce detailed artwork or industrial labels. Leather, on its part, offers a unique texture, thus being good at making personalized wallets, belts, etcetera. Different materials interact with lasers in various ways, hence affecting the depth contrast and general quality of an engrave, which requires an understanding of specific engraving properties if one wants to achieve optimal results.

The Do’s and Don’ts of Laser Engraving Various Materials

To be able to laser engrave, you need to know what materials can be used in the process. Below are some important “do’s” and “don’ts” that will help direct your technique:

Do’s:

- Conduct a pre-test on a small area of the material to check for the laser’s compatibility and adjust settings as necessary.

- Clean the material both before and after engraving for the best finish; especially metals and plastics which can leave behind residue.

- Apply protective coatings on metals to improve engraving quality and prevent damage.

Don’ts:

- Do not engrave PVC or any other material that gives off toxic fumes when it is being lasered.

- Never overlook the thickness of your chosen material; thicker materials may need multiple passes or an adjusted focus for clean, deep engravings.

- Avoid rushing through by using too high speed or power levels, as this can cause uneven engravings or damage to the workpiece.

How to Set Up for Different Materials: A Fast Guide

Customizing laser settings for different materials is important if you want the desired engraving outcomes. This article will give you a summary on how to do it effectively.

Test First: Always start with lower power setting and then increase gradually. Each material absorbs energy from the laser in its own way, so figuring out what works best is key.

- Material Thickness: If you have thicker materials, try slowing down or increasing power so that laser can cut through them well enough. Conversely, with thinner ones, higher speeds and lower powers prevent burning.

- Resolution Settings: High resolution settings work great on metals or hard plastics which can handle intricate designs. Lower resolutions should be used when working with softer materials such as wood or leather to avoid too much burning.

- Focus: You need proper focus because an unfocused laser will not engrave properly at all. Make sure that it is focused correctly onto the surface of your workpiece by either moving the machine closer or further away from it until everything looks sharp and clear.

- Frequency (Hz): Lower frequency (pulse rate) often works better on harder materials like metal as it gives more energy per pulse hence engraving deeper. On soft surfaces, higher frequencies are good because they leave a smoother finish.

Optimize these settings towards your specific material type and every engraving will come out neat-looking every time!

How to Discover the Greatest Deals and Customer Reviews

Finding Reliable Feedback: Interpreting Customer Reviews

When interpreting customer reviews, look for feedback from verified buyers to ensure its genuineness. Seek detailed reviews that transcend mere satisfaction or dissatisfaction because they usually reveal more about how well the product performed and its durability. In addition to considering the number of positive and negative reviews, also take into account what criticisms were made against it and how the company responded to these complaints — which is indicative of their quality of customer service. Websites with structured review systems that allow prospective buyers to ask questions answered by previous customers are invaluable resources; such platforms enable shoppers to make informed decisions based on others’ experiences with similar goods/services. Do not forget that while individual comments may be useful sometimes, patterns within feedback can tell you a lot about reliability or performance issues associated with a given item.

Where to Buy: Amazon Prime vs Direct Sellers vs Specialty Shops

Each option has its own benefits when it comes to where one should buy laser engraving machines or materials. For those who want things done fast without much hassle, Amazon Prime offers quick deliveries alongside a wide variety of products, thus making them suitable for people looking for convenient returns policies too but don’t mind paying slightly higher prices than elsewhere. Alternatively, direct sellers often have lower costs due to cutting out middlemen as well as being able give advice straight from manufacturers themselves, especially if dealing with specialized equipment or requiring custom solutions; this can save time and money in such cases, so considering this wouldn’t hurt either way – besides there’s nothing wrong about getting expert opinion right? Then again, specialty shops serve specific markets and hence boast high levels of customer care plus knowledge about what works best where, so when looking for guidance regarding personalization during the purchase decision-making process around engraving needs, these places become must-visit points; moreover, their unique products could also come in handy someday somewhere somehow so why not check them now? Ultimately, where you decide will depend on what matters most to you, be it price, speed, expert advice, or product niche specialization.

Previewing and Testing: Ensuring You’re Making The Right Choice

To ensure that you are making the correct choice for a laser engraving machine, consider previewing and testing it whenever possible. Attend trade shows or go to manufacturer showrooms where they’re in action; this lets you see them up close and personal. Not only can you judge the quality yourself by inspecting the engravings produced under different conditions, but you also ask any technical questions about how these devices work best on various materials, etcetera. If there is no way to test them directly, then look out for online demonstrations done by trusted industry experts or video reviews made by such people, too, which would suffice greatly in helping one with deciding which product suits their needs most appropriately before committing oneself finally through purchasing either of these items .

Emerging Techs and What’s Next for Portable Laser Engravers?

The Evolution of Laser Technology: Carbon Dioxide to Diode & Infrared

The change has been great over time in terms of laser technology used during engraving, starting from carbon dioxide (CO2) all through the diode alongside current infrared lasers. For many years now, CO2 lasers have remained popular due to their flexibility when cutting diverse materials coupled with high-efficiency levels achieved in doing so within the minimum time frames possible. However, this came into being after some people invented diode ones, which are smaller than those mentioned earlier but consume less power while at the same time being able to etch metals that may be problematic using CO2 technology together with plastics, among other things like this which need higher precision rates during marking processes than any other kind available today besides saving space as well because they don’t require much area.

Dual Laser Systems and IR Engraving: Pioneers of Portable Laser Technology

In the portable laser technology sector, dual laser systems and IR engraving are at the forefront as they usher in a new age of efficiency, precision, and flexibility. Dual laser systems combine two or more laser sources into one machine, which sometimes means different types of lasers are employed to complement each other’s strengths. For example, a CO2 laser could be paired with a diode; this would allow users to switch between or use both at once depending on the material being worked on as well as desired outcome. By doing so, these double-pronged methods enable better abilities, such as working with a wider range of materials or achieving finer details that may not be achieved by single-laser systems.

On the other hand, IR engraving focuses specifically on using infrared light; these have been found to excel in producing high-energy beams that work best for making clean cuts through hard surfaces while still revealing small details during the engraving process. Some advantages associated with this type of technology when incorporated into portable laser engravers include:

- Accuracy and detail improvements: Traditional lasers cannot produce such fine lines therefore resulting in more complex designs becoming difficult or impossible thus making them unsuitable for industrial applications where precision is key. In such cases an infrared (IR) wavelength can come in handy since it allows one to achieve much higher resolution than what would otherwise be possible using any other kind of system.

- Efficiency with tough materials: There exist some metals like copper that tend to reflect most visible wavelengths but readily absorb those emitted within the near-IR region, thereby making it possible for lasers operating at longer wavelength ranges, e.g., 1064nm Nd: YAG or 10µm CO2 types easily penetrate deeply into these substrates before getting reflected back out again hence causing localized heating along their path until reaching the point where final ablation occurs due mainly to heat accumulation effects caused by multi-pass interactions between incident radiation and material atoms.

- High Speed: IR engraving systems work fast, hence reducing production time, thereby increasing business or hobbyist throughput, especially for those targeting high productivity levels.

By combining the dual approach of laser systems with the infrared capabilities in engraving, it becomes possible for the portable laser engraver to be used in a wider range of projects both commercial and personal. This is not only an improvement on traditional lasers but also opens up endless possibilities for creators and innovators across different fields.

Predicting the Future of Laser Engraving Machines

Looking forward, there are several main directions in which the laser engraving industry may develop. Among them is likely to be a prominent place for AI and machine learning, which can make operations more self-directed and accurate when it comes to engraving details. Another trend expected to come up has to do with environmental considerations whereby machines will be made sustainable by the use of energy-saving technology while adopting eco-friendly materials for engraving purposes. Additionally, engravings will get smaller, thereby becoming more convenient for personal use or for small businesses that need such services frequently done on-site. Lastly, material possibilities are set to increase through advancements in lasers’ capabilities, hence enabling designers and creators from different sectors to achieve unimaginable artistic expressions.

Reference sources

- Source: “Exploring Portable Laser Engravers for On-the-Go Creators” – Maker Pro Blog

- Summary: Maker Pro Blog’s online article talks about portable laser engravers. Their portability, compactness, and user-friendliness are the main focus of the discussion. It also emphasizes that these devices are not only designed for people working remotely but also for those with limited spaces to operate in. The report highlights some important specifications as well as potential uses and tips on how to select an appropriate engraving machine.

- Source: “A Comparative Study of Portable Laser Engravers for DIY Enthusiasts” – Journal of Digital Fabrication

- Summary: To help do-it-yourselfers choose a device, The Journal of Digital Fabrication offers a side by side comparison of portable laser engraving machines sold today, evaluating factors such as precision in engraving, compatibility with software and portability.

- Source: “Portable Laser Engraver Solutions for Small Businesses” – Glowforge Manufacturer Website

- Summary: Glowforge’s maker website demonstrates lots of portable laser engravers for small enterprises, featuring their user-friendliness, cloud-based software integration and customer triumphs. It also gives ideas about how these machines can simplify production processes and improve product personalization.

Frequently Asked Questions (FAQs)

Q: What are diode lasers used for in portable laser engravers?

A: Diode laser is a title that refers to the kind of technology placed in portable laser engravers, which allows them to be accurate when engraving at fast speeds.

Q: In what ways are portable laser engravers different from traditional laser engraving machines?

A: They are much smaller and more compact than their traditional counterparts, so they can be carried around and used anywhere. This makes them great for small-scale projects or on-the-go tasks.

Q: Can portable laser engravers work on materials such as acrylic and wood?

A: Yes, portable laser engravers can work with many different materials, including but not limited to acrylics, woods, plastics, leathers, even some metals.

Q: What is the quickest laser engraver that can be moved around and easily sold in stores?

A: Among the most rapid portable laser engravers is the Xtool F1, which is known for its high precision and efficiency when it comes to engraving tasks.

Q: Why should one opt for an infrared-enabled portable laser engraver?

A: When dealing with complex patterns or intricate engravings, a portable laser engraver with IR tech will provide the necessary precision and accuracy.

Q: In what ways does Laserpecker 2 supersede other portable laser engravers?

A: The thing that makes Laserpecker 2 unique is that it has a small size and can be carried from place to place easily, its ability to perform accurate engravings on various materials like metal, wood, plastic or acrylic.

Q: What role does a rotary attachment play in relation to portable laser engravers?

A: A rotary attachment enables portable laser engravers to carve on cylindrical objects such as bottles or glasses, thereby widening the types of projects that can be done using this machine.