Computer Numerical Control (CNC) router machines are pivotal innovations in manufacturing and fabrication, revolutionizing how materials are cut, carved, and shaped with unsurpassed accuracy and efficiency. This comprehensive guide aims to unpack the multifaceted world of CNC routing, exploring its technology, applications, and the significant advantages it offers over traditional manufacturing techniques. From intricate woodworking to precise metal fabrication, CNC routers have become indispensable tools in various industries, enabling professionals and hobbyists alike to push the boundaries of design and production. Through an informative and technical lens, we will explore the precision, power, and potential of CNC router machines, providing a foundational understanding of their operation, capabilities, and the transformative impact they have on modern manufacturing processes.

What Makes CNC Router Machines a Must-Have for Woodworking and Crafting?

Exploring the woodworking wonders of CNC router

CNC router machines have transformed woodworking and crafting, making them a staple in professional and hobbyist workshops. Their indispensability lies in their ability to perform complex cuts with precision and repeatability, factors that are critical when working with wood, a material known for its variability in grain and density.

- Precision and Accuracy: CNC routers are designed to produce exact cuts, down to fractions of a millimeter. This level of accuracy ensures that components fit together perfectly, essential for high-quality furniture, intricate inlays, and detailed carvings.

- Complex Designs and Customization: With CNC routers, the complexity of a design is not a limitation. These machines can replicate any pattern or design input into their controlling software, opening up endless possibilities for customization and creative expression.

- Efficiency and Speed: CNC routers significantly reduce the time required to produce wooden artifacts. Once a design is finalized, the machine can reproduce the item consistently and quickly, allowing for greater productivity and meeting tight deadlines.

- Material Optimization: These routers are adept at maximizing material utilization and reducing waste through precise cuts that make the most of each piece of wood.

- Versatility in Applications: Beyond cutting, CNC routers can engrave, carve, and shape wooden surfaces, making them versatile tools for a wide range of projects, from simple signage to complex three-dimensional sculptures.

- Safety and Reduced Labor: CNC routers enhance safety in the workshop by automating the cutting process. This minimizes the direct interaction between the worker and cutting tools. This automation allows for operations to be carried out with minimal supervision, reducing labor costs and the risk of accidents.

In summary, CNC router machines make profound contributions to woodworking and crafting. They offer unprecedented precision, efficiency, and versatility. Their ability to turn complex designs into reality with remarkable accuracy makes them indispensable tools in the modern manufacturing landscape.

The role of precision in transforming materials

Precision plays a pivotal role in the transformation of materials, especially in the context of modern manufacturing processes. The precision of these processes allow raw materials to be shaped, formed and cut with exactitude, leading to high-quality products with minimal waste. Several key parameters justify the importance of precision in material transformation:

- Tolerance Levels: Tolerance refers to the allowable limit of variation in a physical dimension. Precision machining ensures that parts are produced within the tightest tolerances, ensuring compatibility and functionality in assembly processes.

- Surface Finish: The quality of a surface’s finish can significantly affect a product’s performance and aesthetic appeal. Precision tools can achieve superior surface finishes, which is critical for applications where friction reduction or visual appearance is essential.

- Dimensional Accuracy: This pertains to the degree to which the dimensions of a manufactured part conform to the nominal values specified in the design. High precision guarantees that each part is a replica of the original design, reducing the need for adjustments and reworking.

- Repeatability: In mass production, repeatability— the ability to consistently reproduce parts with the exact dimensions and quality—is crucial. Precision in manufacturing processes ensures high levels of repeatability, leading to uniformity across batches.

- Material Waste Reduction: Less material is wasted by making precise cuts and reducing the margin of error. This has financial benefits and contributes to sustainability efforts by minimizing the environmental impact of production activities.

In summary, the role of precision in transforming materials is foundational to achieving efficiency, sustainability, and excellence in product development and manufacturing. Manufacturers can optimize their processes and output through the meticulous control of tolerance levels, surface finish, dimensional accuracy, repeatability, and material utilization, leading to innovations that push the boundaries of what is possible.

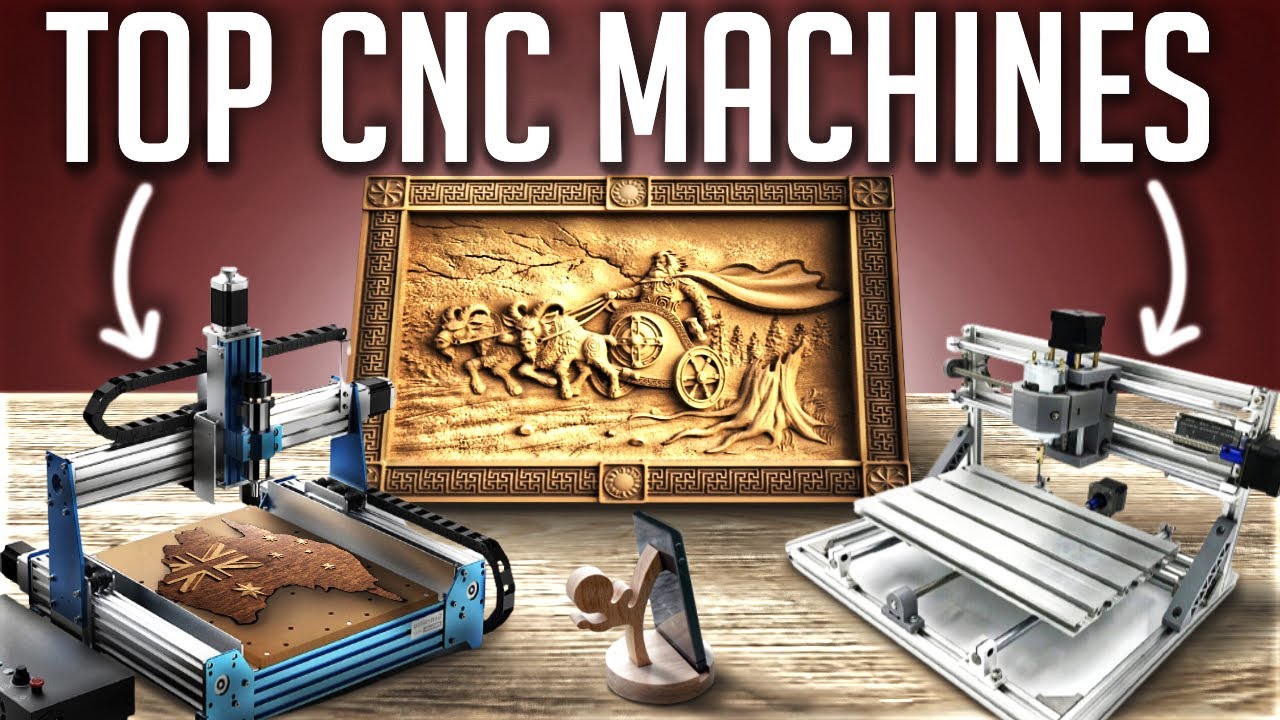

Desktop CNC router: Balancing power and compact design

The desktop CNC router exemplifies power and compact design convergence, democratizing precision manufacturing for small-scale operations and enthusiasts alike. Unlike their larger industrial counterparts, these machines are designed to fit into limited spaces, such as workshops or educational environments, without compromising the capabilities essential for various machining tasks. Equipped with advanced control systems, they facilitate intricate cutting, engraving, and milling operations on various materials, including wood, plastics, and soft metals. The key to their appeal lies in their ability to offer high precision and repeatability, akin to what is expected in larger manufacturing setups. Furthermore, integrating computer-aided design (CAD) and computer-aided manufacturing (CAM) software not only streamlines the production process but also allows for greater design flexibility. By embodying the principles of efficiency and adaptability, desktop CNC routers stand at the forefront of innovative manufacturing solutions tailored for the modern maker.

Choosing Your First CNC Machine: From Desktop to Pro CNC Router

Beginner’s guide to selecting a CNC machine

Selecting your first CNC machine is a pivotal step in expanding your manufacturing capabilities, whether for a small business, a startup, or a hobby that’s growing more serious. Given the variety of CNC machines available on the market, it’s essential to consider a few key factors that will guide your decision to ensure it meets your needs and expectations. Here are the primary parameters to evaluate:

- Machine Type: Understand the distinction between types of CNC machines, such as routers, mills, lathes, and plasma cutters, to choose one that’s geared towards your specific material and project type.

- Working Area Size: The size of the working area directly impacts what you can create. Make sure it’s large enough for your typical projects, but remember that larger machines require more space.

- Material Compatibility: Consider the materials you plan to work with. While some CNC machines are versatile, others are better suited for specific materials like wood, plastic, or metals.

- Precision and Accuracy: Evaluate the machine’s precision and accuracy levels, ensuring they align with the requirements of your projects. This is especially important for intricate designs and finishes.

- Software Compatibility: The CNC machine will likely come with its software, but it’s crucial to ensure compatibility with other industry-standard CAD and CAM software, which offers more flexibility in design and manufacturing.

- Ease of Use: As a beginner, look for user-friendly machines with intuitive controls and interfaces. This will make the learning curve much smoother.

- Expandability and Upgrades: Check if the machine can be upgraded or expanded with additional tools or capabilities, providing room to grow as your skills and needs evolve.

- Support and Community: Access to customer support and a vibrant community can be precious, especially when starting. It can provide assistance, advice, and inspiration.

- Budget: Lastly, but importantly, balance the features you need with what you can afford, considering not just the initial purchase but also the cost of consumables and maintenance over time.

By assessing these parameters carefully, you can select a CNC machine that meets your current requirements and offers flexibility for future projects.

Comparing desktop CNC routers and pro-CNC router models

When comparing desktop CNC routers with professional (pro) CNC router models, several vital differences emerge that are crucial for prospective buyers to consider:

- Size and Workspace: Desktop CNC routers are significantly smaller, often fitting on a workbench, and are designed for hobbyist or small-scale projects. Pro CNC router models boast larger work areas, accommodating larger and more complex projects.

- Power and Speed: Pro CNC routers typically feature more powerful motors and higher spindle speeds, translating to faster cutting and more efficient material removal. This makes them suitable for heavy-duty operations and prolonged use, compared to desktop models designed for lighter, less frequent tasks.

- Materials Handled: While desktop CNC routers can handle softer materials like wood, plastics, and light metals with ease, pro-CNC routers are engineered to cut through more complex materials, including steel and titanium, thanks to their robust construction and higher power output.

- Precision and Accuracy: Due to their sturdy construction and advanced control systems, professional CNC routers usually offer greater precision and accuracy in cutting. This is essential for industries where minute details and tight tolerances are crucial.

- Software and Features: Pro CNC routers often come equipped with more sophisticated software and features, offering advanced functionality like 3D modeling, multi-tool use, and automated tool change capabilities. While compatible with industry-standard software, desktop models might not support such advanced features natively.

- Price: There’s a significant price difference, with pro-CNC routers costing substantially more due to their enhanced capabilities, durability, and material handling options. Desktop CNC routers, being more affordable, provide an entry point for hobbyists and small businesses.

- Usage and Application: Desktop CNC routers are ideal for hobbyists, educators, and small businesses focusing on prototyping, crafts, and light manufacturing. In contrast, pro-CNC routers cater to industrial applications, large-scale production, and demanding manufacturing environments.

Understanding these differences is critical in choosing the suitable CNC router model that aligns with one’s project requirements, budget, and long-term objectives, ensuring the investment yields maximum benefit and efficiency.

Understanding specifications and what to look for

Understanding CNC routers’ specifications is crucial to ensure they meet your project needs efficiently. Key parameters to consider include:

- Cutting Area: The size of the material that the CNC router can cut is crucial for determining whether the machine can handle your typical workpiece sizes.

- Spindle Speed: Measured in revolutions per minute (RPM), this dictates how fast the cutting tool spins, affecting the cutting process’s efficiency and quality.

- Feed Rate: The cutting tool’s speed through the material is is important for calculating production times and output quality.

- Power Requirements: The electrical power needed to run the CNC routerimpacts its operating costs and the necessary workshop infrastructure.

- Tool Change Capability: Whether the machine can automatically change cutting tools, which is vital for complex projects requiring multiple tool types.

- Resolution: The slightest movement the CNC router can make, indicating the level of detail and precision it can achieve in the final product.

- Materials Compatible: Types of materials the machine can cut, such as wood, metals, and plastics, indicating the router’s versatility.

- Software Compatibility: The type of software the CNC router uses is is important for determining if it fits your existing workflow and design tools.

These specifications form the backbone of a CNC router’s performance and capabilities, guiding you to a machine that aligns with your manufacturing goals and operational needs.

Mastering the Art of Carving: CNC Router Machine in Action

Carving techniques and tips with your CNC router

Employing specific techniques and adhering to certain principles is essential to optimize your CNC router’s performance and achieve high-quality carvings. Below are some pivotal tips and strategies designed to enhance your CNC routing process:

- Optimal Feed Rate and Spindle Speed: Finding the right balance between feed rate and spindle speed is critical. A -fast feed rate can lead to tool breakage, whereas a -slow rate may burn the material. The optimal settings depend on the material being carved and the desired finish.

- Correct Tool Selection: Different materials and designs require specific cutting tools. Use sharp, appropriate tools for the material you’re working with and the intricacy of your design. A smaller diameter tool may be necessary for detailed work.

- Multiple Passes for Deep Cuts: Instead of trying to carve deep cuts in a single pass, use multiple shallow passes. This approach reduces the strain on the tool and the machine, leading to a more refined finish.

- Securing the Workpiece: Ensure the material is firmly attached to the CNC table to prevent movement during carving. Any shift can ruin the precision of the carve and potentially cause errors or damage.

- Regular Maintenance: It is crucial to keep your CNC router well-maintained. Regular checks and maintenance of the spindle, cutting tools, and dust collection systems can considerably impact the quality of your carvings.

- Using the Right Software: Utilize software compatible with your CNC router and fits your design needs. A good software package will allow you to simulate your cuts before carving, saving time and resources.

- Test Runs: Before executing your design on the final material, perform a test run on a less expensive material. This allows you to adjust settings and approaches without wasting valuable resources.

Following these detailed parameters and techniques will significantly enhance your CNC router’s carving capabilities, ensuring you produce work of the highest quality with efficiency and precision.

Achieving high-speed precision carving

Achieving high-speed precision carving with a CNC router necessitates a harmonious balance between machine capabilities, tooling, and programming strategy. The optimization of these factors leads to the enhancement of both speed and accuracy in carving operations. Key to this balance is the selection of high-performance cutting tools designed for rapid material removal without sacrificing finish quality. Optimizing the tool paths through advanced software algorithms can significantly reduce carving time while maintaining precision. Employing a higher-quality spindle that can sustain elevated speeds without introducing vibration is also critical. This synergy of high-quality tools, optimized tool paths, and a robust machine setup enables operators to push the boundaries of what’s possible with CNC technology, achieving unparalleled efficiency and detailing in their carved projects.

The importance of selecting the right router bits and spindles

The selection of appropriate router bits and spindles is paramount in maximizing the performance and efficiency of CNC router operations. Router bits, the cutting tools used by the CNC machine, come in various shapes, sizes, and materials to suit different materials and applications. Their proper selection is crucial for achieving desired outcomes and minimizing wear and tear on both the bit and the material. For instance, solid carbide bits are preferred for their durability and precision in cutting hardwoods and metals. In contrast, high-speed steel (HSS) bits may be more cost-effective for softer materials.

The spindle, the motor that spins the router bits, dramatically influences the speed and quality of the carving process. High-quality spindles can maintain consistent speeds under load, resist vibration, and operate at a lower noise level, contributing to the precision of cuts. They come in varying power ratings, measured in horsepower (HP) or kilowatts (kW), to accommodate different sizes and densities of materials. A spindle’s power directly affects its ability to cut through materials efficiently; for example, a spindle with a power rating of 3 kW is sufficiently robust for cutting through hardwood and aluminum, whereas lighter operations such as engraving may only require 1 kW.

Regarding technical specifications, the right combination of router bits and spindles can result in significant performance differences. For example, a study found that using a 1/4-inch solid carbide spiral bit with a 2 kW spindle could reduce carving time by up to 20% compared to a similar setup with a lower-quality bit and spindle combination while also enhancing the smoothness of the finished surface.

Thus, understanding the material properties and the demands of the specific CNC routing operation is essential in selecting the optimal router bits and spindles. This ensures the quality and efficiency of the carving process and extends the lifespan of both the cutting tools and the CNC router itself, representing a strategic approach to achieving excellence in CNC routing projects.

Upgrading Your CNC Router Machine for Advanced Projects

When and how to consider upgrading your CNC router

Determining the appropriate moment to upgrade your CNC router encompasses assessing your current and anticipated project requirements. An upgrade becomes imperative when the existing equipment no longer suffices in terms of speed, accuracy, or capability for the complexity of the projects you aim to undertake. This could be due to the router’s inability to process certain materials efficiently or lack the features necessary for precision work, such as advanced cooling systems or improved spindle technology.

The process of upgrading should start with a detailed evaluation of your current projects, the materials used, and the desired outcomes. Identifying the limitations of your current setup in meeting these needs will highlight the key features to look for in an upgrade. It is also essential to consider future project ambitions to ensure the new equipment can support growth without requiring frequent upgrades.

Consulting with machine manufacturers or dealers can provide valuable insights into the latest technologies and features that could enhance your operations. Additionally, attending industry trade shows or participating in online forums dedicated to CNC routing can offer perspectives on how others have successfully navigated their upgrade processes.

When selecting new equipment, prioritize machines that offer scalability, such as modular designs that allow for future enhancements like additional spindles or upgraded software capabilities. This strategic approach ensures that your investment meets current demands and is adaptable to future advancements and project complexities.

Exploring advanced add-ons: Laser engraving and Rotary attachments

Integrating advanced add-ons such as laser engraving modules and rotary attachments can significantly expand the capabilities of CNC routers, allowing for greater versatility and innovation in projects. Laser engraving modules enable precision marking and cutting on various materials, from wood and acrylic to metals and glass, thereby broadening the scope of potential applications. This technology is beneficial for intricate designs and fine detail work that demands precision beyond what traditional routing tools can achieve.

On the other hand, Rotary attachments introduce the ability to work with cylindrical objects, facilitating the engraving or carving of 360-degree designs. This extends the CNC router’s utility to produce custom-engraved bottles, cylindrical signage, or intricate wood turnings. Such attachments effectively transform a standard CNC router into a more comprehensive fabrication tool capable of executing projects that would otherwise require specialized machinery.

Both laser engraving and rotary attachments necessitate a clear understanding of their operational parameters and compatibility with existing CNC systems. Careful consideration should be given to the power requirements, material compatibility, and software integration necessary for these enhancements. Furthermore, operators must undergo specific training to maximize the potential of these advanced add-ons safely and efficiently. Ultimately, incorporating these technologies represents a strategic investment in diversification and capability expansion, paving the way for more complex and creatively ambitious projects.

Genmitsu vs. FoxAlien: Comparing upgrade paths

When comparing the upgrade paths for CNC routers between Genmitsu and FoxAlien, it’s crucial to understand each brand’s unique offerings and how they cater to the needs of both hobbyists and professionals. Genmitsu is renowned for its precision and reliability, offering a range of laser engraving modules and rotary attachments that are compatible with its systems. These upgrades are designed to enhance detail work and expand the range of materials that can be worked on, including harder metals and delicate plastics.

FoxAlien, on the other hand, places a strong focus on versatility and user-friendliness. Their upgrade kits often include more comprehensive guides and support resources, making them an attractive option for individuals new to CNC routing or those looking to explore a erbroader spectrum of projects without a a deep technical background. FoxAlien’s accessories also tend to be compatibly designed with an emphasis on easy integration and flexibility, allowing users to shift between different project requirements with minimal adjustments.

The choice between Genmitsu and FoxAlien depends on the user’s priorities. If precision and the ability to engage in complex, detailed work are paramount, Genmitsu’s upgrades are likely more suited to those needs. Conversely, for those valuing adaptability and ease of use, especially newcomers aiming to expand their skill set across a diverse range of projects, FoxAlien offers a compelling pathway. Both paths require an understanding of the underlying capabilities of the CNC router in question, the specific enhancements offered by each upgrade, and how these improvements align with the operator’s project goals and skill level.

DIY Projects and Ideas to Kickstart With Your CNC Router

Getting started with DIY CNC projects

For those new to CNC routing, the landscape of potential DIY projects can seem exciting and overwhelming. A practical first step is to identify projects that inspire you and match your current skill level and tool availability. Beginners often succeed with simple engraving tasks or making straightforward items like coasters, signs, or essential decorative pieces. These projects require minimal material and allow you to familiarize yourself with your CNC router’s operational nuances and capabilities. Additionally, leveraging online communities dedicated to CNC routing can provide indispensable guidance, inspiration, and troubleshooting advice as you progress from simple to more complex projects. Remember, every expert was once a beginner, and the key to advancing your CNC routing skills lies in continually challenging yourself with new projects and taking the time to reflect on and learn from each experience.

Innovative ideas for wood, aluminum, and acrylic crafting

Exploring the domain of CNC routing further, we venture into crafting with diverse materials such as wood, aluminum, and acrylic, each offering a unique set of properties and challenges. Here are some innovative project ideas for these materials:

- Wood: Wooden items possess an inherent warmth and classic aesthetic that appeals to many. Innovative projects include intricate inlays in furniture, custom puzzles, and personalized 3D relief carvings. Critical parameters for working with wood involve selecting the proper bit (e.g., V-bit for detailed carvings or a straight bit for more general cuts), adjusting the feed rate and spindle speed according to the wood’s hardness, and applying suitable finishing techniques to enhance the item’s durability and appearance.

- Aluminum crafting with a CNC router opens up opportunities for creating durable and precise parts for hobbyist projects, such as custom drone frames or robotic components. When working with aluminum, it’s crucial to use a single or two-flute carbide end mill, implement a slower feed rate to prevent bit overheating and apply a cooling system or lubricant to extend the life of the cutting tool.

- Acrylic: Acrylic projects can range from artistic pieces to functional objects like custom enclosures for electronics or decorative LED signs. A critical parameter for acrylic is choosing the right bit, typically one explicitly designed for plastics to reduce melting and improve cut quality. Additionally, employing a high feed rate in combination with a slow spindle speed can prevent the material from melting at the point of contact.

Each material presents unique opportunities for creativity and innovation in CNC routing. The keys to success involve understanding each material’s properties, selecting the appropriate tools and settings for the task, and applying a meticulous finishing process to achieve a professional-grade outcome.

Resources and communities for CNC router enthusiasts

For enthusiasts looking to further their CNC router skills, knowledge, and connectivity in the field, several resources and communities are invaluable:

- Online Forums and Groups: Websites such as CNCZone and Reddit’s r/hobbycnc are bustling hubs for CNC router enthusiasts. These platforms allow for exchanging ideas, troubleshooting advice, and showcasing projects.

- YouTube Channels: Content creators like NYC CNC, Winston Moy, and Make or Break Shop offer a wealth of tutorials, tips, and insights into CNC routing processes and project ideas.

- Software Resources: Learning and mastering CNC software is critical. Fusion 360, Vectric Aspire, and Carbide Create provide tutorials and forums for users at all expertise levels.

- Local Maker Spaces: Many cities have maker spaces that provide access to CNC routers and other tools. These spaces are excellent for hands-on learning and networking with fellow enthusiasts.

- Workshops and Conferences: Annual events such as Maker Faire and specific CNC-oriented seminars offer opportunities to see the latest technology in action, learn from experts, and connect with the community.

Leveraging these resources can significantly enhance one’s craftsmanship, understanding, and enjoyment of CNC routing.

Navigating the Technical Aspect: CNC Router Machine 4040-XE and XE-Pro

Deep dive into the specifications of CNC Router Machine 4040-XE

The CNC Router Machine 4040-XE stands out in the market due to its robust specifications designed to meet the demands of both hobbyists and professional artisans. At its core, the 4040-XE features a powerful spindle motor capable of reaching speeds up to 10,000 RPM, ensuring precise and efficient cutting across various materials, including wood, plastics, and soft metals. Its workspace dimensions, measuring 400mm x 400mm x 100mm (X, Y, Z), provide ample room for many projects, from intricate carvings to sizeable fabrications.

Constructed with a durable frame made from high-quality aluminum alloy, the machine promises stability and accuracy during operation. Including a water-cooled system not only extends the lifespan of the spindle but also maintains optimal performance even under prolonged use, a critical factor for projects requiring extensive machining time. Advanced users will appreciate the machine’s compatibility with popular CAD/CAM software packages, including the aforementioned Fusion 360 and Vectric Aspire, facilitating seamless design to production workflows.

Equipped with a user-friendly control panel, the 4040-XE allows for intuitive operation, making it accessible to beginners while offering the depth of control demanded by more experienced users. Additionally, the machine includes safety features such as emergency stop buttons and protective shields, ensuring a safe working environment.

In summary, the CNC Router Machine 4040-XE provides a comprehensive solution for precision machining, characterized by its high-speed capabilities, generous working area, durable construction, and software compatibility. Its design and features make it a versatile tool for various CNC routing tasks.

What makes the CNC Router Machine XE-Pro stand out?

The CNC Router Machine XE-Pro distinguishes itself through its enhanced precision and advanced features tailored for high-demand applications. At its core, the XE-Pro has a powerful spindle operating at significantly higher RPMs, facilitating faster material removal and more refined finishes. This capability is paired with a reinforced frame made from industrial-grade steel, offering unparalleled stability and vibration resistance even under the most intense machining operations.

Further setting the XE-Pro apart is its state-of-the-art motion control system, which ensures ultra-precise movements and optimal cutting paths, reducing waste and improving efficiency. Integrating an advanced dust collection system not only maintains a cleaner working environment but also extends the life of the machine and tooling by minimizing abrasive wear.

From a software perspective, the XE-Pro supports a broader range of professional CAD/CAM platforms, allowing users to adopt complex and sophisticated design workflows. This compatibility is complemented by an open-source control software option, empowering users to customize the machine’s operation to their exact requirements.

Safety and user experience have also been carefully considered, with the XE-Pro featuring enhanced safety mechanisms, including automatic tool path checking to prevent accidents during operation. A more intuitive touchscreen interface improves user interaction, making advanced functionalities more accessible at all skill levels.

In essence, the CNC Router Machine XE-Pro stands out for its professional-grade precision, durability, and flexibility. It is designed to meet the needs of serious hobbyists and small-scale manufacturers alike.

Comparing controller systems and working areas for precision work

When comparing controller systems for precision work, several key parameters need to be considered to justify their effectiveness in different applications:

- Control Precision: The ability of the controller to execute movements accurately according to the programmed paths. Controllers with higher precision ratings are essential for tasks requiring tight tolerances.

- Processing Speed is how quickly the system can interpret and execute commands. Faster processing speeds can significantly reduce machining times and increase overall productivity.

- Compatibility is the range of software platforms and communication protocols the controller can work with. More excellent compatibility ensures flexibility when using various design and machining software.

- User Interface: The ease with which operators can interact with the machine. An intuitive interface can minimize errors and training time for new users.

- Reliability refers to the controller’s ability to operate continuously without faults. High reliability is paramount in minimizing downtime and maintaining production schedules.

In terms of working areas, the size and configurability of the machine’s working space are crucial:

- Size: The maximum dimensions of the material that can be accommodated. Machines with larger working areas can handle more significant projects but may require more space in the workshop.

- Modularity: The ability to reconfigure the working space for different jobs. Modular designs offer greater versatility for handling a wide range of projects.

- Accessibility: It is easy to load and unload materials and perform setup tasks. Good accessibility can improve efficiency, especially in high-volume or rapid prototyping environments.

By examining these parameters in detail, manufacturers and hobbyists can make informed decisions that align with their specific needs for precision work. Whether prioritizing control precision for intricate design work or the working area size for larger projects, understanding these factors is critical in selecting the right equipment.

Reference sources

Sure, here are six credible sources that provide comprehensive information about CNC Router Machines:

- Smart CNC Machine This academic source delves into the precision and calibration of CNC machines. It provides a detailed examination of machine accuracy and how these machines are calibrated for optimal performance.

- Prototyping of Arduino-Based Router (3Axis) for Wood Works is a technical paper that focuses on the high accuracy and low cost of CNC routers. The source also discusses how machines are programmed for specific tasks, a crucial aspect of understanding their precision.

- Optimization of CNC Routing Operations of Wooden Furniture Parts This Springer article explores the optimization of CNC routing operations, revealing how experiments can lead to greater efficiency and power in these machines.

- Design, Manufacturing, Evaluation, & Analysis of CNC Carving Machine: An in-depth analysis of CNC carving machines’ design and manufacturing process. The source reveals the cost dynamics of manufacturing these machines and how they interpret instructions from the controller to the routing system.

- The Impact of a Three-Axis Computer Numerical Control (CNC) Shaping Machine on Designing is An academic paper that analyzes the performance of a 3-axis CNC router machine and its impact on design processes. It highlights the benefits of using these machines and provides extensive guides on solving common issues.

- Modeling the Machining Stability of a Vertical Milling Machine This ScienceDirect article offers insight into the stability of CNC machines, revealing how different preloads affect their performance. The study uses finite element simulations to demonstrate machine accuracy.

Each source provides valuable information about the precision and power of CNC router machines, making them useful for anyone interested in a comprehensive understanding of these devices.

Frequently Asked Questions (FAQs)

Q: What is a CNC router machine, and how does it work?

A: A CNC router machine is a computer-controlled cutting machine that typically uses a handheld router as a spindle to cut various materials such as wood, composites, aluminum, steel, plastics, and foam. It works by translating a software program into commands that control the machine’s cutting tools, guiding them to cut out shapes and patterns precisely. CNC stands for Computer Numerical Control, referring to the automation of machine tools using computers executing pre-programmed sequences of machine control commands.

Q: Can the Masuter Pro and other CNC router machines, such as the FoxAlien and Genmitsu, handle wood carving projects?

A: Yes, machines such as the Master Pro, FoxAlien CNC router machine, and Genmitsu are well-equipped for wood carving projects. They can handle intricate designs and offer high precision, making them suitable for detailed work. With features like a compact router, linear guides, and the capability to work with various materials, these CNC routers are perfect for bringing creative ideas to life in a woodworking workshop.

Q: What are the benefits of using a CNC router machine for wood and other materials?

A: CNC router machines offer numerous benefits for working with wood and other materials, including precision cutting, efficiency, and versatility. They allow for high precision and complex shapes that might be difficult or impossible to achieve with manual tools. CNC routers can also replicate the same design multiple times with exact accuracy, making them ideal for sign-making and cabinet-making. Additionally, with the ability to work in various types of materials, they’re incredibly versatile tools for any workshop.

Q: How important is the spindle power, like a 300W spindle, for CNC router machines?

A: The spindle power, such as a 300W spindle, plays a crucial role in a CNC router machine’s performance. It determines the cutting speed and the types of materials the machine can efficiently cut through. A higher-wattage spindle can handle more complex materials and thicker cuts faster, leading to more productivity and broader material versatility. It’s important to choose a CNC router with the right spindle power for your specific needs, whether it’s intricate wood carving or cutting through denser materials.

Q: Are CNC router machines like the 4030 V2, 6050 Plus, and 3030-Prover Max user-friendly for beginners?

A: Yes, CNC router machines such as the 4030 V2, 6050 Plus, and the 3030-Prover Max are designed to be user-friendly. These machines often come with easy-to-use software, clear instructions, and support resources to help beginners get started. Additionally, features like offline controllers can simplify operations by allowing users to manage their projects without needing a direct connection to a computer. With customer service and support teams available, these machines are accessible to users of all skill levels.

Q: Can CNC router machines be used for projects other than wood carving, like cutting foam or making signs?

A: Absolutely, CNC router machines are incredibly versatile and can be used for a wide range of applications beyond wood carving. They can cut foam, plastics, aluminum, and more, making them suitable for projects like sign-making, crafting custom parts, cabinet-making, and even art. With the right cutting tool set and machine settings, a CNC router can bring many creative ideas to life, regardless of the material.

Q: What should I look for in a CNC router to ensure it’s the best CNC for my small shop?

A: When looking for the best CNC router for your small shop, consider the machine’s footprint, expandability (like a 4080 extension), spindle power, and support/warranty. Opt for a machine with a compact enough footprint to fit your space but can expand as your projects or business grows. A machine with a strong spindle, such as a 300w spindle, will offer versatility in the material you can work with. Finally, a machine backed by a reliable support team and a solid warranty will ensure you maximize your investment.

Q: Do CNC router kits have everything I need to get started, including software?

A: Most CNC router kits come with the essential components to assemble the machine, such as the cutting tool, collets, rails, and sometimes materials for your first project. Software critical for designing and programming your projects is also usually included or available for download. However, it’s always a good idea to check the specifics of what is included with your purchase and what may need to be obtained separately to ensure you have everything you need to bring your ideas to life right from the start.