What is Laser Engraving Stone and How Does it Work?

Laser engraving stone is the process of using high-powered lasers to etch designs onto stone surfaces. This innovative technique works by focusing a laser beam onto the stone surface to vaporize the material, leaving behind a permanent and precise mark. It’s a non-contact, thermal-based process that ensures that the stone is not physically damaged during marking. This technique is increasingly popular due to its precision and versatility, enabling intricate designs on a range of stone types including granite, marble, and basalt. Laser engraving on stone finds extensive use in various sectors such as monument engraving, architectural detailing, and decorative art.

Understanding the principles of laser marking on stones

The underlying principles of laser marking on stones revolve around two key aspects: the laser’s power and the absorption characteristics of the stone. The laser’s power, typically measured in watts, dictates the depth and speed of engraving, with higher power enabling deeper and faster engraving. It’s crucial to adjust the power output to match the hardness and color of the stone for optimal results. Darker stones typically absorb more laser energy and therefore require less power compared to lighter stones. The stone’s absorption characteristics also determine the contrast and visibility of the engraving. For instance, smoother stones yield higher contrast markings due to their uniform absorption pattern. Understanding these principles helps achieve the best engraving outcomes and opens up a wide range of artistic possibilities.

Differences between various types of lasers used for stone engraving

In the realm of stone engraving, different types of lasers are used, each with its unique characteristics and advantages. Primarily, there are two types of lasers used: CO2 lasers and fiber lasers.

CO2 Lasers: CO2 lasers are the most common type used for stone engraving. They are characterized by a long wavelength, which allows for an excellent absorption rate on a wide range of materials, including stone. CO2 lasers are known for their precision, allowing for intricate designs and high-detail engraving. However, they tend to be larger and require more maintenance than fiber lasers.

Fiber Lasers: Fiber lasers, on the other hand, use a different type of technology. They generate a laser beam by using an optical fiber doped with rare-earth elements. Fiber lasers are more durable, require less maintenance, and have longer lifespans than CO2 lasers. However, they are typically more expensive and are not as widely used for engraving on stone due to their shorter wavelength which is not as well absorbed by stone materials.

When choosing the type of laser for stone engraving, one must consider factors such as the type of stone to be engraved, the desired level of detail, the engraving speed, and the overall budget for the project.

Choosing the right stone for laser engraving

Choosing the right stone for laser engraving is an essential step to ensure a successful outcome. Stones can vary greatly in hardness, grain, and density, factors that can influence the result of the engraving. Marble is a favorite choice due to its uniform density and fine grain, which allows for precise, detailed engraving. Granite is also commonly used for its durability and the contrast it offers when engraved. Slate, with its fine grain and uniformity, is a popular choice for both indoor and outdoor applications. More exotic stones such as onyx and travertine can also be used, offering unique aesthetics. However, these stones are softer and may require more care during the engraving process. Ultimately, the choice of stone depends on the desired aesthetic effect, the purpose of the engraved piece, and the characteristics of the chosen laser system.

The importance of laser power and speed in stone engraving

The selection of the appropriate laser power and speed plays a critical role in the quality and efficacy of stone engraving. Higher laser power can carve deeper into the stone, providing a pronounced and permanent engraving. However, a caveat is that too much power can cause the stone to crack or chip, potentially ruining the engraving. On the other hand, lower power settings can be used for intricate, detailed work, or more delicate stones.

Laser speed is another crucial aspect to be considered. A slower speed allows the laser to make a deeper impact for a high-contrast finish, but it also increases the engraving time. Conversely, a higher speed results in a lighter engraving and is suitable for creating delicate, intricate patterns. The right balance of power and speed must be tailored not only to the specific type of stone being used but also to the level of detail desired in the engraving.

It is equally important to note that the settings for power and speed depend on the machine’s specifications and the properties of the specific stone. Therefore, testing on a sample piece before proceeding with the actual engraving may be advisable.

Common applications of laser-engraved stone products

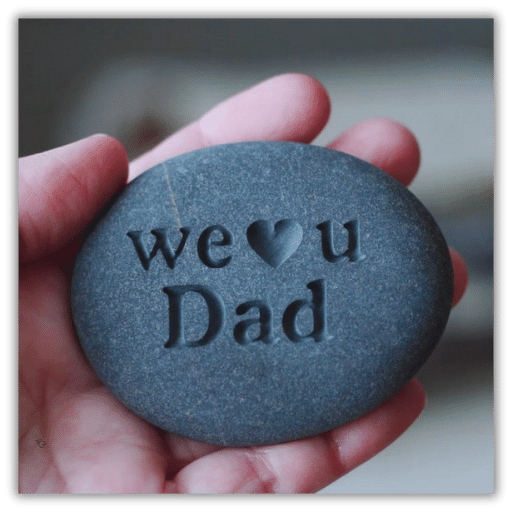

Laser-engraved stone products are widely used in a variety of sectors due to their durability, beauty, and versatility. One common application is in the creation of personalized home decor items such as engraved stone fireplace mantels, garden stones, or bespoke kitchen backsplashes. In the world of business, stone engraving is often used for creating high-impact signage or promotional items that make a statement. In the realm of arts and crafts, stone engraving can be used in jewelry making, creating unique, personalized pieces. Additionally, memorial stones and plaques are often laser-engraved, allowing for a high level of detail and a truly personalized tribute. Lastly, in the construction industry, laser-engraved stone is used for intricate architectural detailing and design elements. These applications exemplify the vast potential of laser-engraved stone products.

Choosing the Right Laser Engraving Machine for Stone

Choosing the right laser engraving machine for stone involves a careful consideration of several key factors. Firstly, it’s essential to consider the machine’s power level. Stone engraving requires a machine with sufficient power to carve into the hard surface, so a higher-wattage machine may be necessary for harder stones.

The size of the machine’s engraving area is another crucial consideration. Depending on your projects, you might need a machine with a larger working area. If you plan to work on small stones for jewelry, a small working area would suffice. For larger projects such as architectural detailing or signage, a larger engraving area would be more suitable.

The machine’s resolution is another critical factor. Higher-resolution machines can provide more detailed engravings, which can be particularly important for intricate designs or when working with fine-grained stones.

Support and warranty are also essential factors. A machine with good support can help you resolve any issues that arise, and a robust warranty can provide peace of mind.

It’s also recommended to consider the software that comes with the machine. Some machines include proprietary software, while others may require third-party software. The right software should be user-friendly and should support the design file types you plan to use.

Finally, cost is a key factor. While you may be tempted to go for the cheapest option, it’s essential to consider the machine’s features and the support offered by the manufacturer. A higher upfront cost can sometimes result in greater long-term value. It’s therefore crucial to consider all these factors together, and not just focus on any one aspect in isolation. This can help ensure that you choose the right laser engraving machine for your specific stone engraving needs.

Exploring different types of laser engraving machines for stone

There are several types of laser engraving machines for stone, each with distinct features and capabilities.

CO2 Laser Engravers: These machines use a carbon dioxide gas mixture to produce the laser. CO2 laser engravers are versatile and can be used to engrave on a variety of materials including stone. They are particularly good at engraving detailed images into surfaces.

Fiber Laser Engravers: In contrast to CO2 models, fiber laser engravers use a solid gain medium, making them more effective for engraving harder materials like stone. They offer high precision and durability, consequently making them more expensive.

Green Laser Engravers: These types of laser engravers are ideal for engraving on heat-sensitive materials. However, they can also be used for stone engraving and offer a high-quality finish.

UV Laser Engravers: UV laser engravers are typically used for high-precision engraving, especially on materials that are sensitive to heat. While they are capable of engraving stone, they are better suited for delicate and precise work.

When choosing a laser engraving machine, it is important to consider the type of stone you will be working with, as different types of stones may require different types of lasers. Always consult with the manufacturer or an expert to ensure you select the right machine for your needs.

Considerations for selecting the best laser engraver for stone material

Selecting the best laser engraver for stone material involves several key considerations.

Material Characteristics: The hardness, density, color, and texture of the stone can affect the engraving outcome. Softer stones like limestone might require less power, while harder stones like granite may require a more potent laser.

Engraving Precision: The level of detail necessary for the engraving is also a significant factor. For intricate designs, a machine like the UV laser engraver, known for its precision, maybe a better choice.

Speed and Efficiency: If you’re operating on a commercial scale, the speed of the engraving process may be crucial. Fiber laser engravers, for instance, are highly efficient and durable, making them suitable for large-scale operations.

Cost Effectiveness: While high-end machines like fiber and UV laser engravers offer excellent precision and speed, they come with a higher price tag. Depending on your budget, a CO2 laser engraver might be a more cost-effective option.

Maintenance and Durability: The operational costs, including maintenance and part replacement, also need to be considered. Engravers with solid-state lasers, like fiber and UV laser engravers, generally have longer service lives and require less maintenance.

Ease of Use: Lastly, the user interface and software compatibility are important for smooth operation. Machines that come with user-friendly software and good technical support can make the engraving process much more manageable.

Advantages of CO2 laser versus fiber laser in stone engraving

- Versatility: CO2 lasers are capable of engraving on a wide range of materials, including stone, wood, glass, and plastic, making them more versatile compared to fiber lasers which mainly work with metals.

- Lower Initial Cost: The purchase price of CO2 laser engravers is typically lower than fiber lasers, making them a more affordable choice for small businesses or individual artists.

- Higher Quality on Non-Metal Materials: While fiber lasers excel on metals, CO2 lasers often deliver better quality on non-metal materials, including stone. They can produce smoother gradients and softer edges, which are essential for detailed and intricate designs.

- Lower Power Consumption: CO2 lasers generally use less power than fiber lasers during the engraving process, leading to lower operational costs.

- User-friendly: CO2 lasers are known for their user-friendly nature. Their setup and operation processes are typically straightforward, making them ideal for beginners in the engraving industry.

Etching and marking capabilities of laser engraving machines on stone

Laser engraving machines, particularly CO2 lasers, exhibit remarkable etching and marking capabilities on stone. They can create detailed, high-resolution designs with impressive accuracy and precision. These machines work by emitting a laser beam that heats the stone surface, causing it to vaporize in a controlled manner. This results in a permanent, weather-resistant mark that won’t fade over time. The depth of the engraving can also be adjusted, providing flexibility for various design requirements. It’s important to note that different types of stone, such as granite, marble, or basalt, may react differently to the laser, affecting the final appearance of the engraving. CO2 lasers are particularly effective for engraving softer stones, while harder stones may require multiple passes for a more pronounced effect.

Key features to look for when purchasing a stone laser engraving machine

- Power and Speed: The power and speed of the laser engraving machine significantly affect the quality and efficiency of the engraving process. Higher power allows for deeper engravings and faster operation, while adjustable speed provides flexibility for different design requirements.

- Working Area Size: Depending on your specific needs, the size of the machine’s working area is crucial. For larger projects, a bigger working area is necessary.

- Material Compatibility: Ensure the machine is capable of engraving your desired types of stone. Some machines are better suited to softer stones like marble, while others can handle harder stones like granite.

- Ease of Use: Consider a machine with user-friendly software and controls, especially if you are a beginner. A straightforward setup process and intuitive interface can save time and reduce the learning curve.

- Reliability and Durability: The machine should be robust and reliable, capable of operating for long sessions without needing frequent maintenance or repairs.

- Customer Support: Opt for brands that offer excellent customer support and after-sales service. This feature can be invaluable for troubleshooting and maintenance advice.

- Budget: Last but not least, consider your budget. While higher-priced machines often offer more features and capabilities, you must balance this with your specific needs and financial constraints.

Best Practices for Laser Engraving on Different Stone Types

When it comes to laser engraving on different types of stones, specific practices can enhance the result of your project.

- Marble: Marble is relatively soft and responds well to laser engraving. Use lower power settings and high-speed rates to achieve fine details without causing cracks or chipping.

- Granite: Granite is a harder stone, which requires higher power settings for effective engraving. However, patience is key—try multiple passes at a lower power setting instead of one pass at high power to prevent damage.

- Slate: Slate’s layered structure can cause flaking during engraving. To prevent this, use a lower power setting and adjust the speed accordingly.

- Limestone and Sandstone: These stones can differ in hardness significantly, and they may contain sand or other particulates that can interfere with engraving. Test your settings on a scrap piece before engraving your final work.

Remember, always clean the stone surface thoroughly before engraving to remove any dirt or dust that could interfere with the laser’s path. Always conduct a small test on an inconspicuous area or scrap piece of the same material before starting the actual engraving. This will help you to fine-tune your machine settings and obtain the best possible results.

Understanding the properties of marble for laser engraving

Marble is a metamorphic rock primarily composed of calcite or dolomite. It’s characterized by its fine grain and variable color patterns, which can range from pure white to richly multicolored. In terms of hardness, it’s softer than granite and slate, making it a favorable material for laser engraving. Its softness allows for intricate detailing without causing unwanted fractures or chipping. However, due to the variations in color and vein patterns, engraved designs might appear inconsistent in color tone and depth. The smoother and more homogeneous the marble surface, the cleaner and more precise the engraving result. Understanding these properties can help optimize your laser power settings and engraving strategy for marble. Always remember to perform a test engrave on a non-visible or scrap section of the marble to ensure optimal engraving settings for the specific piece.

Efficient techniques for laser engraving on granite and slate

Granite and slate, both igneous rocks, have unique characteristics that require specific engraving techniques. When dealing with granite, its hardness and grainy structure can be challenging. Therefore, using a high-power laser along with slow engraving speed can produce the best results. The laser should be focused precisely to ensure optimal depth and clarity of the engraving. It is also advisable to use multiple passes instead of a single high-power pass to prevent surface damage.

Slate, on the other hand, has a layered structure that can peel or flake off during the engraving process. To minimize this, a lower power setting and faster speed are recommended. Ensure the slate surface is clean and free from dust before engraving. As with granite, multiple passes can be beneficial to achieve the desired depth without causing excessive surface damage. As a general rule, always conduct a test engraving on an inconspicuous area or scrap piece of the same material before starting the actual engraving. This will enable you to determine the most effective laser settings for your project.

Exploring possibilities of laser marking on tile, acrylic, and brick

Each material presents unique challenges and possibilities when it comes to laser marking.

Tiles, especially ceramic ones, are laser-friendly due to their glazed surface. However, the color and type of glaze can affect the contrast and clarity of the mark. A low-power setting with high speed is often effective, but testing is crucial to determine the optimal settings.

Acrylic, on the other hand, absorbs infrared light very efficiently, making it an excellent material for laser marking. Clear acrylic, when engraved, turns a frosty white color, providing excellent contrast. However, due to its sensitivity to heat, the power and speed settings must be carefully controlled to prevent melting or warping.

Brick, a porous and uneven material, can be a challenge for laser marking. However, with a sufficiently powerful laser, high-quality results can be achieved. The marking process creates a permanent, water and fade-resistant mark, ideal for outdoor applications.

As always, it’s recommended to perform a test marking on a non-visible or scrap section of the material to fine-tune your laser settings.

Special considerations for laser engraving on metal and ceramic stones

Metal and ceramic stones, while different in their composition, both require careful handling when it comes to laser engraving.

For metals, not all types respond well to laser marking without pre-treatment or the use of marking compounds. Precious metals, for instance, are difficult to engrave directly and may require a specialized laser system. The heat produced during the process can also cause changes in the coloration of the metal, resulting in a unique, but sometimes unpredictable, appearance.

Ceramic stones, on the other hand, are typically more receptive to laser marking. However, the hardness and density of the stone can influence the effectiveness of the laser. High-density stones may require a higher power setting or slower engraving speed to achieve a clear, deep engraving. The color of the stone can also affect visibility, with darker stones often producing better contrast.

As with any material, it’s advisable to carry out a test engraving on a hidden area or scrap piece to ascertain the optimal settings.

Optimizing laser settings for pebble, marble, and other stone types

Just like metals and ceramics, pebbles, marble, and other stone types require specific considerations when determining optimal laser settings. For pebbles, the irregular surface can present unique challenges. Make sure to adjust the focal point of your laser to account for any variations in depth. You may need to engrave at a slower speed to ensure the laser effectively marks the stone’s surface.

Marble, on the other hand, is a relatively homogenous material with a smooth surface. It generally responds well to laser engraving, with white marble providing the best contrast. However, marble’s relative hardness might necessitate the use of higher power settings for deeper engraving.

For other stone types, the critical factors to consider are color, density, and texture. Lighter-colored stones typically provide better contrast, whereas high-density stones might require higher power settings or slower speeds. Always remember to conduct a test engraving on an inconspicuous or scrap piece of the material to fine-tune your settings.

Mastering the Art of Precision Marking with Laser Engraving Systems

Mastering the art of precision marking with laser engraving systems is a craft rooted in understanding the nuances of your material and the fine-tuning of your equipment. The depth, speed, and power of the laser engraver must be delicately balanced to achieve the desired effect. The focal point of the laser, for instance, needs continuous adjustment for irregular materials like pebbles, while harder, denser materials may necessitate higher power settings.

The chosen engraving speed equally plays a pivotal role. A slower speed can often lead to deeper, clearer engravings, especially for harder materials like marble. Further, it’s crucial to comprehend the impact of color and texture differences among various stones. For example, lighter-colored stones typically provide superior contrast, boosting the visibility of the engraving.

In essence, mastering precision marking with laser engraving systems is about practice, patience, and a keen understanding of the interplay between the laser settings and the material characteristics. Always remember that conducting a test engraving on an inconspicuous or scrap piece of material is an invaluable step in perfecting your engraving technique.

Maximizing the engraving area with different laser systems

Maximizing the engraving area with different laser systems is a crucial step to optimize productivity and enhance the quality of the outcome. Depending on the size and type of the material, the engraving area needs to be accurately determined to ensure efficient usage of the laser system.

For larger materials, utilizing a laser system with a wider engraving area may be necessary to complete the job without needing to reposition the material. Conversely, smaller, more intricate designs may benefit from a laser system with a smaller engraving area, offering a greater level of precision.

In addition to the size of materials, the shape also influences the selection of the laser system. Flat materials require different handling than curvilinear or irregularly shaped ones, as the latter may necessitate rotary attachments to maximize the engraving area.

Therefore, understanding the capabilities and limitations of different laser systems and tailoring them to the specifications of your material is key to maximizing the engraving area, thereby ensuring efficient and high-quality laser engraving outcomes.

Overview of stone engraving and marking using diode and fiber lasers

Stone engraving and marking using diode and fiber lasers is a sophisticated process that offers high precision and fine detailing. Diode lasers, with their narrow wavelength light, are particularly suitable for engraving materials with darker shades like granite or basalt. They work by heating the material, causing it to vaporize, thus leaving a permanent mark. On the other hand, fiber lasers employ a different technology. Their beam quality and operational wavelength make them ideal for engraving lighter-colored stones. They create high contrast and highly detailed images by directly modifying the stone’s surface structure. Both types of lasers have their specific advantages, and understanding their distinct qualities can help determine which one is best suited for a particular stone engraving project. Hence, the selection of either a diode or fiber laser would depend on the material characteristics of the stone and the required level of detail for the engraving.

Customization and personalization with logo and text laser engraving on stones

Customization and personalization through logo and text laser engraving on stones have opened up a plethora of opportunities for businesses and individuals alike. This technique allows for the creation of uniquely designed merchandise, corporate gifts, memorials, or even personalized jewelry. With precision and high resolution, laser engraving can accurately reproduce intricate logos and fonts on stone surfaces. The engraving depth can also be adjusted, offering a range of aesthetic choices from subtle markings to deep impressions. Furthermore, the permanency of laser engraving ensures that these unique designs will not fade or wear over time, making them suitable for both indoor and outdoor applications. Whether it’s a company logo, a favorite quote, or a loved one’s name, laser engraving offers an unparalleled level of customization and personalization on stone materials.

Exploring the capabilities and limitations of desktop laser engraving machines

Desktop laser engraving machines offer the convenience of compact size and ease of use, making them an ideal choice for small businesses and hobbyists. These machines are capable of engraving a variety of materials, including stones, with a high degree of precision and detail. They can reproduce intricate designs and fonts, making them suitable for personalized engravings.

However, desktop engravers also have their limitations. The engraving area is typically smaller than that of industrial laser machines, limiting the size of the projects that can be undertaken. Also, while they are capable of engraving a range of materials, they may not perform as well on harder stones compared to industrial-grade machines. Furthermore, the lifespan of their laser diodes may not be as long as those found in commercial-grade machines, resulting in a need for more frequent replacements. Finally, while desktop machines are generally user-friendly, they still have a learning curve and require an understanding of design software and machine operation.

How to achieve intricate designs with laser engraving on stone surfaces

To achieve intricate designs with laser engraving on stone surfaces, there are several steps to follow. First, one must choose an appropriate design that will work well with the material and surface of the stone. Complex designs with fine details often work best on smooth, flat surfaces.

Next, the design must be digitized using graphic design software, such as Adobe Illustrator or CorelDRAW. It is important to ensure that the design is set to the correct size and resolution for the stone to be engraved.

Once the design is prepared, it can be sent to the engraving machine. The laser parameters like speed, power, and dpi (dots per inch) must be set properly, depending on the stone material and the intricacy of the design. Higher resolution settings can provide better detail but may take longer to engrave.

The stone should be placed in the machine ensuring it is level, clean, and secure. After a final check of the design and settings, the engraving can begin.

Lastly, after the engraving process is complete, it’s recommended to clean the stone surface to remove any residue, which will enhance the final appearance. The same process can be repeated for multiple stones or designs.

With the right design and laser settings, laser engraving can create intricate and personalized designs on stone surfaces, adding a unique touch to any piece.

Ensuring Quality Results: Tips for Optimizing Laser Engraving on Different Stone Materials

Different stone materials have distinct characteristics, which can impact the laser engraving process and the final result. Here are some tips to optimize your laser engraving process for various types of stone:

- Granite: Highly durable and typically dark in color, granite provides a striking contrast when engraved. Using lower dpi settings (around 150-200 dpi) will give better results.

- Marble: With its smooth surface and lighter color, marble requires a bit more power for engraving compared to granite. A higher resolution (300 dpi) can help maintain the details in your design.

- Slate: Slate’s uneven surface may pose a challenge. It’s recommended to use a lower resolution (150 dpi) with a higher power setting for optimal results.

- Limestone: This softer rock requires less power and speed for engraving. To avoid chipping or damage, use a lower resolution (around 150 dpi) and a slower speed.

Remember, testing different settings on a small piece of the material first can help ensure optimal results. Always clean the stone thoroughly before and after engraving to reveal the true beauty of your design.

Factors that impact the precision and quality of laser engraving on stones

Several factors come into play that can impact the precision and quality of laser engraving on stones:

- Material Characteristics: The type of stone, its color, hardness, and texture, can immensely affect the engraving process. Each material interacts differently with the laser, resulting in varying degrees of contrast, depth, and detail in the final engraving.

- Laser Power and Speed: The engraving’s depth and precision are determined by the laser’s power and the engraving speed. Higher power and slower speed result in deeper engravings, while lower power and faster speed yield shallower engravings.

- Choice of Lens: The lens’s focal length can impact the precision of the engraving. A shorter focal length results in higher precision and finer details but a smaller work area, while a longer focal length provides a larger work area but less detail.

- Quality of Artwork: The quality and resolution of the artwork being engraved will also affect the final result. High-resolution images lead to more detailed engravings.

- Maintenance of Equipment: Regular checks and maintenance of the laser engraving machine can also contribute to the quality and precision of the engraving. Dirty or damaged lenses and mirrors can reduce the laser beam’s quality and precision.

Remember, understanding these factors and how they interact will allow you to optimize your process for the best possible results.

Overcoming challenges in laser processing for specific stone types

Certain stone types pose unique challenges in laser processing. For instance, darker stones like granite offer higher contrast engraving but may require power adjustments to prevent excessive material burn. Lighter stones, such as limestone or marble, can struggle with contrast, although this can be mitigated by applying a color fill post-engraving.

- Granite: This stone provides excellent contrast due to its dark natural color; however, it’s crucial to find a balance with the laser power to prevent overburning. Testing different power and speed settings on scrap material before the actual engraving can help identify optimal settings.

- Marble and Limestone: These stones are typically lighter, which can result in a lack of contrast. After engraving, a color fill can be applied to enhance the visibility of the design.

- Slate: Slate is a soft stone that engraves well at lower power settings. Due to its layered structure, however, the engraving depth must be carefully controlled to prevent the design from flaking off.

Proactive testing on different materials, careful calibration of the laser settings, and post-processing techniques are key strategies to overcoming the challenges associated with engraving specific types of stones.

Maintaining the integrity of engraved stone during post-processing

Preserving the integrity of the stone during post-processing is essential to ensure the longevity and aesthetics of the final product. This can be achieved through careful cleaning and sealing practices.

- Cleaning: After engraving, the stone surface should be gently cleaned to remove any residual debris. This can be done using a soft brush and a mild, non-abrasive cleaning agent. It’s crucial to avoid vigorous scrubbing or harsh chemicals, as these could damage the engraving or the stone surface.

- Sealing: After cleaning, sealing the stone can help to protect it from weathering and other external factors. This is particularly important for porous stones like limestone or marble. The sealant should be applied carefully and evenly, ensuring that it covers the entire surface without pooling in the engraved areas.

In conclusion, post-processing plays a vital role in engraving processes. By implementing proper cleaning and sealing techniques, you can maintain the integrity of the engraved stone, thereby enhancing its durability and aesthetic appeal.

Enhancing the permanence of laser engraving on stones

Ensuring the permanence of laser engraving on stones is a multidimensional task, demanding a careful selection of stones, precise calibration of laser parameters, and meticulous post-processing.

- Selection of Stone: Not all stones are alike. The hardness, color, structure, and composition of stones can greatly affect how they react to laser engraving, impacting the durability of the final product. It’s advisable to opt for harder stones such as granite, as they often produce clearer, more lasting engravings than softer stones like limestone or sandstone.

- Laser Calibration: The intricacies of laser engraving require precise calibration of the laser’s power, speed, and frequency. Too much power can cause deeper engraving, which may lead to flaking or cracking over time. On the other hand, too little power might result in shallow engravings that can fade away with weathering or cleaning.

- Post-Processing: As discussed earlier, post-processing techniques, like cleaning and sealing, are critical for the longevity of the engraving. An additional step could be periodic maintenance, especially for outdoor installations exposed to harsh environmental conditions. Regular cleaning and re-sealing can help preserve the engraving and extend its lifespan.

In essence, enhancing the permanence of laser engraving on stones involves an intertwining of careful stone selection, accurate laser calibration, and diligent post-processing. Understanding these aspects is key to creating engravings that stand the test of time.

Best practices for engraving intricate designs on various stone surfaces

When it comes to engraving intricate designs on various stone surfaces, the following best practices can help ensure the quality and clarity of the final product:

- Vector Images: Use vector images for intricate designs as they offer the flexibility of resizing without compromising the design quality. The sharpness of lines and curves in vector graphics ensures a precise blueprint for the laser to follow.

- High-Resolution Images: For photorealistic engravings, use high-resolution photographs. Adequate resolution ensures the laser accurately reproduces the fine details, resulting in a more clear and detailed engraving.

- Select the Right Stone: Some stones are better suited for intricate designs than others. For example, black granite and marble have a consistent structure that allows for detailed work. Their colors also provide excellent contrast for the engraved design.

- Test Engraving: Always perform a test engraving on a sample piece of stone. This helps in verifying the right calibration settings for the specific design and stone type and allows for adjustments to be made before engraving the final piece.

- Regular Maintenance: For intricate designs, regular maintenance is crucial. Dirt and grime can accumulate in the detailed carvings over time, diminishing the design’s clarity. Regular cleaning with a soft brush and water can help maintain the design’s vibrancy.

Following these best practices can greatly enhance the outcome of intricate engraving designs on various stone surfaces. It’s a balance of correct image selection, adequate testing, and precise laser settings. Regular maintenance also plays a key role in preserving the intricate details over time.

Recommended Reading: 9060 Laser Cutting and Engraving Machine

Frequently Asked Questions

Q: What types of stones can be used for laser engraving?

A: Laser engraving can be done on a wide variety of stones, including granite, marble, slate, and other natural stones.

Q: What is a fiber laser marking machine and how is it used for stone engraving?

A: A fiber laser marking machine is a type of laser engraving machine that uses fiber lasers to mark materials, including stones. It works by emitting a high-intensity laser beam to engrave or etch designs onto the surface of the stone.

Q: What factors should be considered when choosing a cutter for stone engraving?

A: When choosing a cutter for stone engraving, factors such as the type of stone, the desired depth of engraving, and the contrast required in the design should be taken into consideration.

Q: What are some of the common stones used in laser engraving?

A: Some common stones used in laser engraving include granite, marble, slate, and other natural stones. Each type of stone may require different laser settings for optimum results.

Q: How does the power of the laser affect the engraving process?

A: The power of the laser determines the depth and speed of the engraving process. Lower-power lasers are suitable for surface engraving and etching, while higher-power lasers are capable of deeper engraving on stones and other materials.

Q: What is the recommended power range for laser engraving on stones?

A: A power range of around 20W to 30W is commonly recommended for stone engraving. However, the specific power requirement may vary depending on the type of stone and the desired engraving depth.

Q: How does the surface finish of a stone affect the laser engraving results?

A: The surface finish of a stone, such as its polish and texture, can impact the contrast and quality of the engraved design. Different surface finishes may require adjustments to the laser settings for optimal results.

Q: Is laser engraving on stones time-consuming?

A: The time required for laser engraving on stones depends on factors such as the complexity of the design, the type of stone, and the desired engraving depth. However, intricate designs and deep engravings can be time-consuming processes.

Q: What are the benefits of using a fiber laser for stone engraving?

A: Using a fiber laser for stone engraving offers advantages such as high precision, minimal maintenance, and the ability to achieve detailed and intricate designs on various types of stones.

References

- Laser Engraving in the Stone Sector: Applications and Possibilities: This scientific research paper discusses the technological advances and the innovative applications related to laser engraving in the stone sector.

- Laser Engraving Basics: This article from Engravers Journal delves into the fundamentals of laser engraving, including engraving on stone surfaces.

- The Art of Laser Engraving: A Complete Guide: This book offers a comprehensive guide to the process of laser engraving, including on stone surfaces.

- Epilog Laser: Stone Engraving: The Manufacturer’s website offers practical advice and guidance on laser engraving stone, including detailed instructions and guidelines.

- Stone Laser Engraving Machines: Online marketplace featuring a variety of stone laser engraving machines, providing insights into different models and their capabilities.

- Laser Engraving Techniques: This resourceful blog post discusses various techniques for laser engraving, including those specific to stone.

- Modern Methods of Carving: Academic journal article discussing the modern methods of carving, including laser engraving on stone.

- Laser Engraving vs Traditional Engraving: In-depth blog post comparing laser engraving to traditional engraving methods.

- The Detailed Guide on How To Use A Laser Engraver: Comprehensive guide on laser engraving, including recommendations and best practices for engraving on stone.

- Stone Engraving Technical and Safety Guidelines: Official guidelines from OSHA, providing safety instructions for working with stone engraving machinery, including laser engravers.